The rise of electric vehicles (EVs) has marked a significant shift in the automotive industry, driving a new wave of innovation in energy storage and power management. Among the key components ensuring the smooth and efficient operation of electric vehicles, the EV Battery Relay stands out. This critical device plays a pivotal role in managing the flow of electricity from the battery to the motor, as well as protecting the battery from potential damage. In this article, we will explore the function, types, applications, and challenges of EV Battery Relays, shedding light on why they are essential for modern EVs.

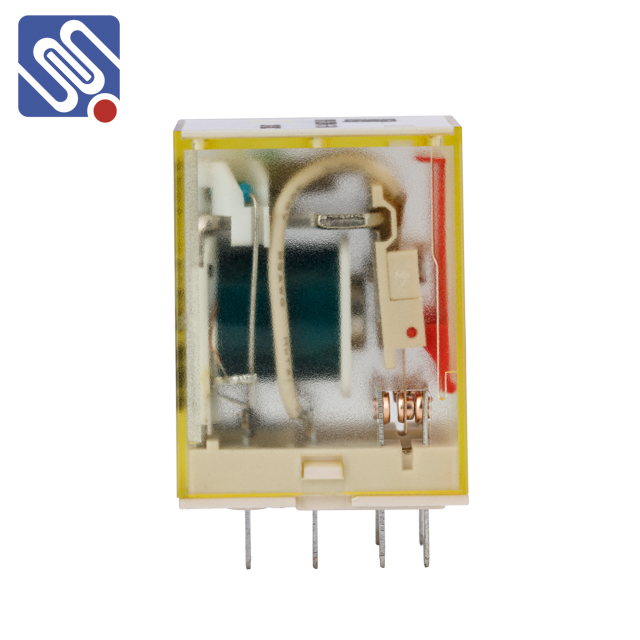

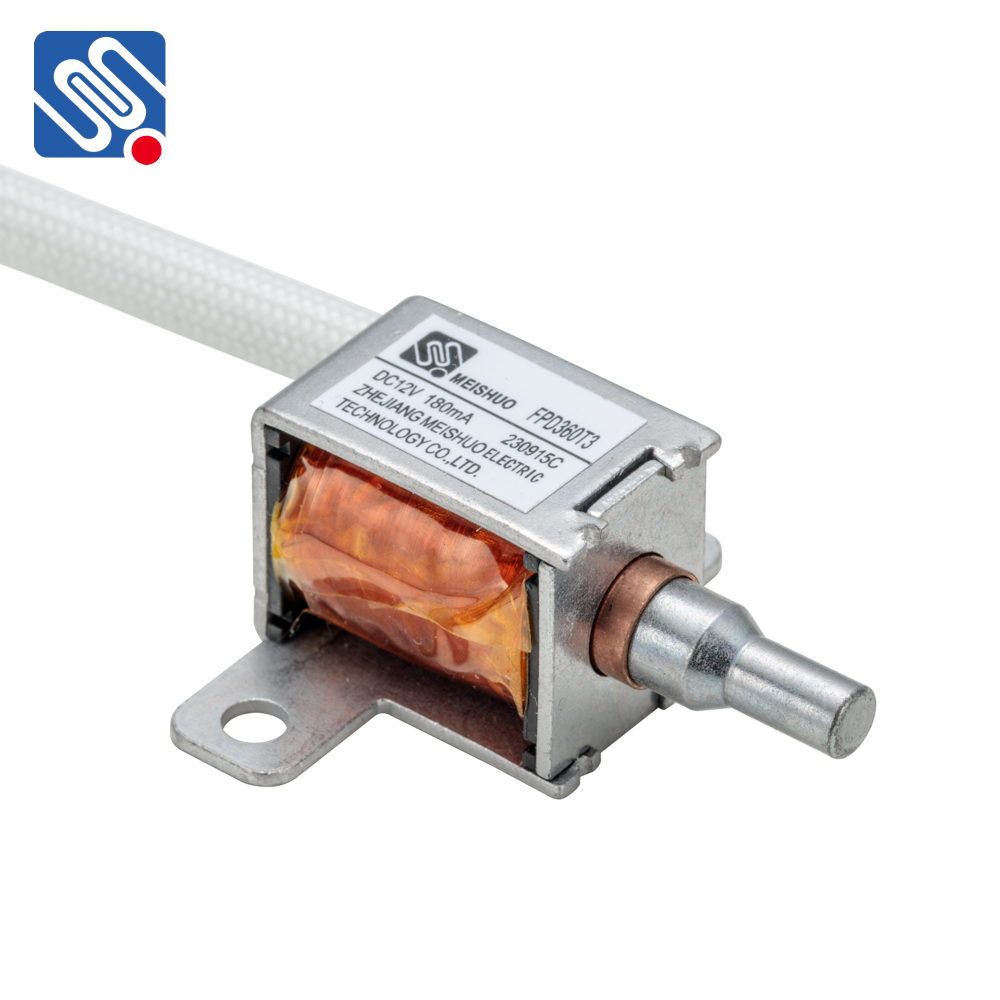

What is an EV Battery Relay? An EV Battery Relay is an electromechanical switch that connects and disconnects the high-voltage battery pack of an electric vehicle to its powertrain and charging system. It controls the flow of electricity from the battery to the motor when the vehicle is in operation and ensures the battery remains disconnected when it is not in use. This relay is vital for the vehicle’s energy management system, as it helps regulate charging, discharging, and protects the battery from harmful conditions such as overcurrent, overheating, and short circuits. Functions of an EV Battery Relay