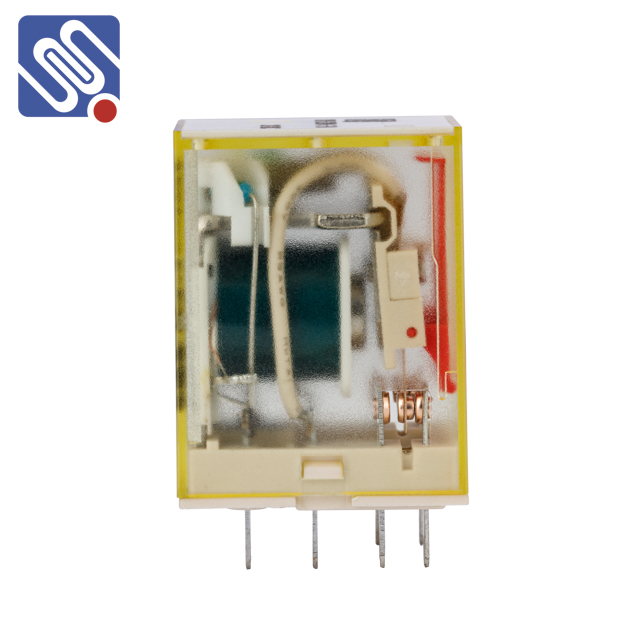

An industrial relay is an essential component in modern automation and electrical systems, playing a vital role in controlling high-power devices with low-power signals. These electro-mechanical devices are widely used across various industries, from manufacturing plants to power plants, ensuring safe and efficient operation of equipment. This article aims to provide a comprehensive overview of industrial relays, including their types, applications, and key features.

What is an Industrial Relay? An industrial relay is an electrically operated switch that allows low-voltage control circuits to switch high-voltage or high-current systems on and off. It consists of an electromagnet (coil), a movable armature, and a set of contacts. When the relay coil is energized, the magnetic field generated attracts the armature, causing the contacts to change their state, either closing or opening the circuit. Industrial relays can be used in a wide range of applications, including automation, control, protection, and safety systems. Types of Industrial Relays Electromagnetic Relays