Durable plastic solenoid valves are an essential component in numerous industries where fluid and gas control are critical. These valves, constructed primarily from durable plastic materials such as polypropylene, PVC, and nylon, offer a reliable and cost-effective solution for managing the flow of liquids and gases. While they are not as commonly associated with high-pressure or extreme-temperature environments as their metal counterparts, durable plastic solenoid valves present several advantages that make them ideal for various applications, especially where corrosion resistance and lightweight design are of paramount importance.

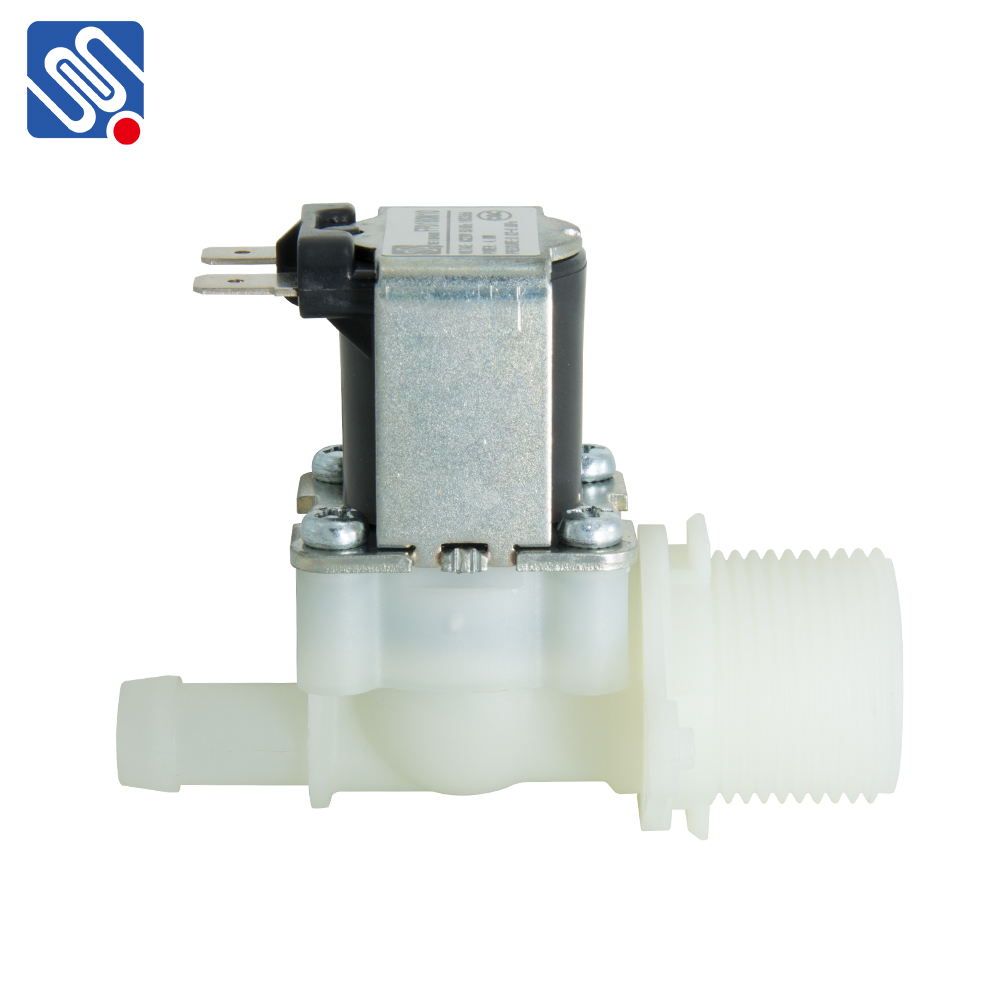

What Is a Durable Plastic Solenoid Valve? A solenoid valve is an electromechanically controlled valve that regulates the flow of liquids or gases within a system. The valve is activated by an electromagnetic coil that, when energized, creates a magnetic field to move the valve’s plunger or diaphragm, which either opens or closes the flow passage. In the case of durable plastic solenoid valves, the body of the valve is made from robust plastic materials that are capable of withstanding exposure to corrosive substances, thus offering long-lasting performance in challenging environments.

Advantages of Durable Plastic Solenoid Valves