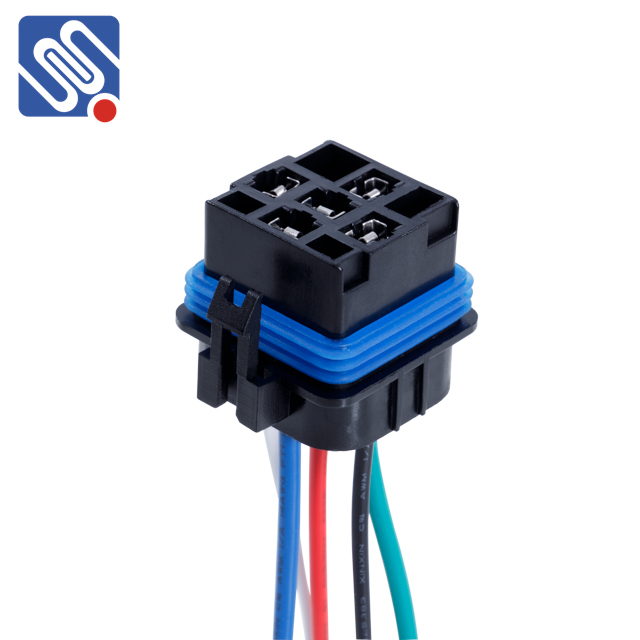

Relay connectors are crucial components in various electrical and electronic systems, enabling the reliable connection between relay devices and external circuits. These connectors provide a practical solution for wiring, ensuring secure electrical contacts and simplifying the maintenance and replacement of relays in different applications. This article explores the importance, types, and applications of relay connectors, offering insights into their essential role in modern electronics and industrial automation.

What Are Relay Connectors? Relay connectors are interfaces designed to link a relay with its power source or controlled devices. A relay, in itself, is an electrical switch that opens or closes a circuit under the control of an external signal, often in low-power circuits. However, to connect a relay to higher-power circuits or systems, relay connectors are used to facilitate a seamless electrical connection, ensuring both safety and efficiency. Typically, relay connectors include pins or terminal blocks that make it easy to attach wires and ensure solid connections for transferring current. Depending on the specific application, relay connectors come in various forms, offering flexibility for different industries and technologies.