In today’s industrial landscape, safety is paramount, particularly in environments where flammable gases, vapors, or dust may be present. One of the critical components used to enhance safety in these hazardous conditions is theexplosion proof electric actuator. These actuators are designed to operate safely in areas classified as hazardous, ensuring that machinery functions reliably without risking ignition of explosive materials. This article explores the design, functionality, applications, and benefits of explosion proof electric actuators.

Understanding Explosion Proof Electric Actuators

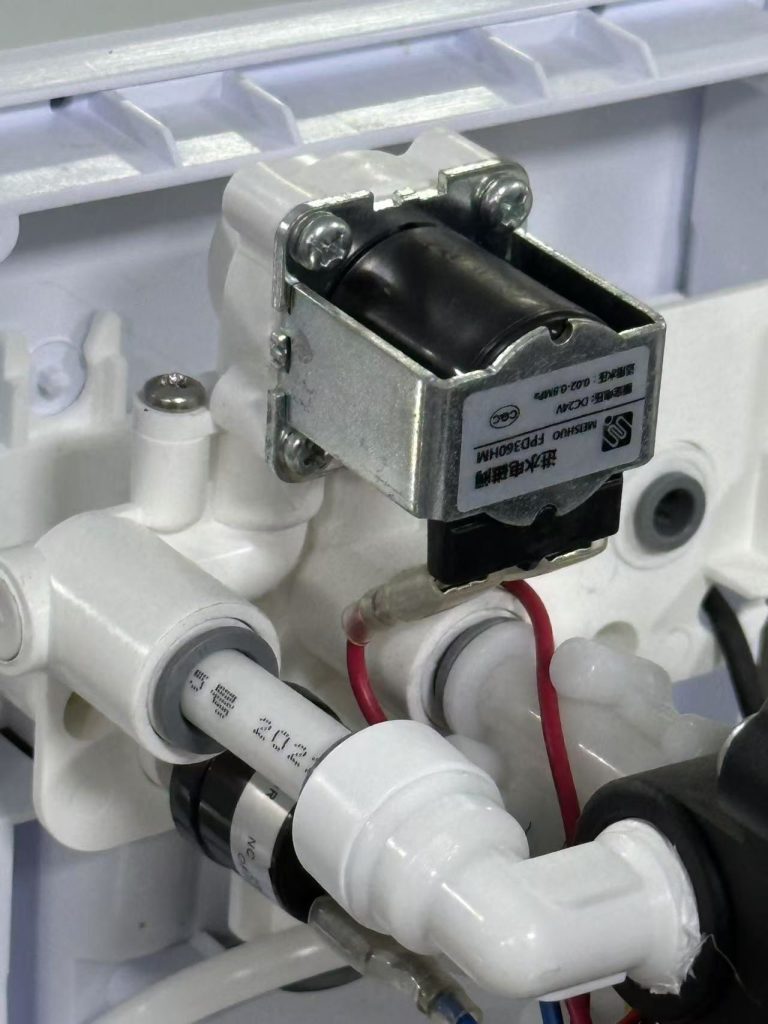

An explosion proof electric actuator is an electro-mechanical device that converts electrical energy into mechanical motion, typically to control the movement of valves and dampers in various industrial processes. These actuators are specifically designed to withstand the harsh conditions often found in hazardous environments. They comply with stringent safety standards and are tested to prevent any ignition sources from escaping their enclosures. The design of explosion proof electric actuators usually features robust materials, such as aluminum or stainless steel, which provide both strength and corrosion resistance. These materials are often treated to resist various chemicals and environmental factors, making them suitable for applications in oil and gas, chemical manufacturing, and other sectors where safety is a concern.