In the rapidly evolving world of industrial automation, the need for reliable and durable components is more critical than ever. One such component that plays a significant role in various automation systems is the electric actuator. For industries where environmental conditions pose a significant challenge, waterproof electric actuators have become a game-changer. As industries push forward to create more robust and efficient systems, waterproof electric actuator manufacturers are at the forefront, ensuring that these essential components can withstand harsh conditions and continue to perform reliably.

Understanding Waterproof Electric Actuators

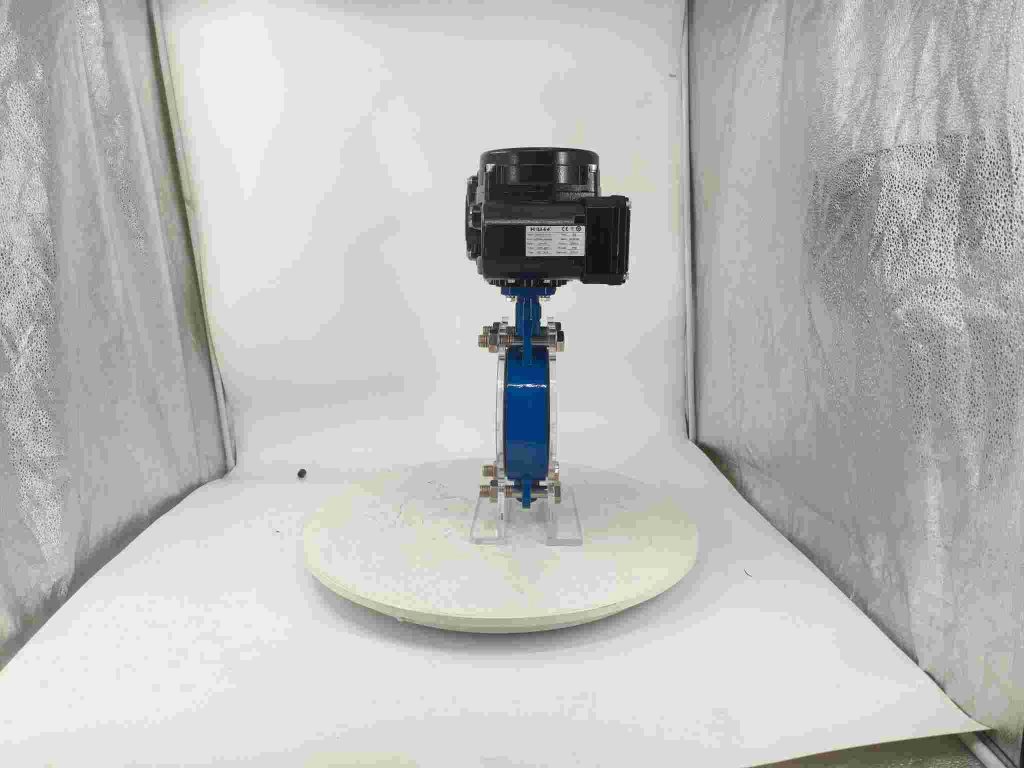

Before diving into the importance of waterproof electric actuators and the role of manufacturers, it’s essential to understand what electric actuators are and why waterproofing is critical. Electric actuators are devices that convert electrical energy into mechanical movement. They are used in a wide array of applications, such as opening and closing valves, controlling the position of machinery parts, and even adjusting mechanical settings in various automated systems. Waterproof electric actuators are designed to operate in environments where they may be exposed to moisture, rain, or even submersion in water. These actuators are crucial for industries like marine, chemical processing, oil and gas, wastewater treatment, and agriculture, where moisture or extreme weather conditions are a constant factor. The primary benefit of waterproof electric actuators is their ability to function without degradation or failure, regardless of the exposure to water or other harsh elements.