In the world of industrial automation, valves are essential components that regulate the flow of liquids, gases, and other materials in piping systems. Among these, the electric flanged butterfly valve stands out for its efficiency, durability, and versatility. As industries continue to grow and demand more advanced solutions, China has emerged as a global leader in manufacturing electric flanged butterfly valves. With advanced technologies, stringent quality controls, and cost-effective production methods, Chinese manufacturers are setting new standards for the global valve industry.

What is an Electric Flanged Butterfly Valve?

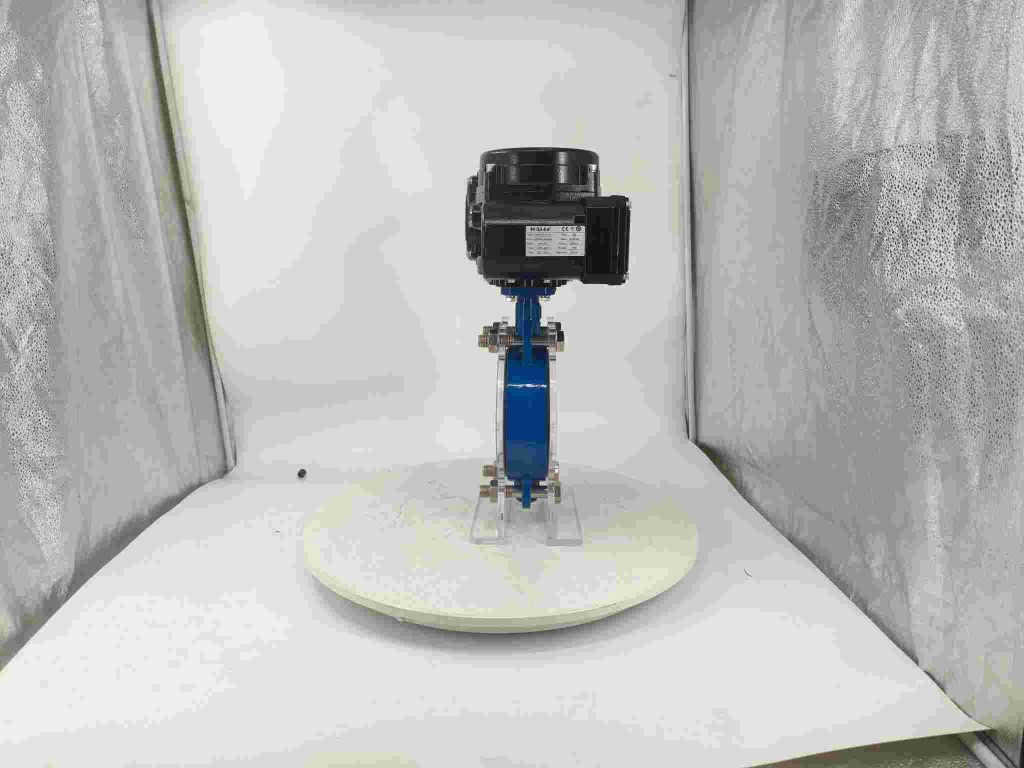

An electric flanged butterfly valve is a type of valve that uses a circular disc to control the flow of substances in a pipeline. The valve is operated by an electric actuator, which rotates the valve disc to either open or close the valve, thereby controlling the flow rate. The “flanged” design refers to the way the valve is connected to the pipeline using flanges that bolt the valve securely in place. This type of valve is commonly used in industries like water treatment, HVAC, oil and gas, and chemical processing, where reliable and automated flow control is essential. Electric flanged butterfly valves offer precise control, low maintenance requirements, and the ability to operate in both high and low-pressure systems, making them an ideal choice for many applications.