An explosion-proof damper actuator is an essential piece of equipment used in a variety of industrial systems, particularly in environments where explosive atmospheres may exist. Designed to operate in high-risk settings, these actuators provide a safe, reliable way to control the flow of air or gases through ductwork while preventing the propagation of flames or explosions. In this article, we will delve into the construction, application, and benefits of explosion-proof damper actuators, highlighting their critical role in safeguarding industries from potential hazards.

What is an Explosion-proof Damper Actuator?

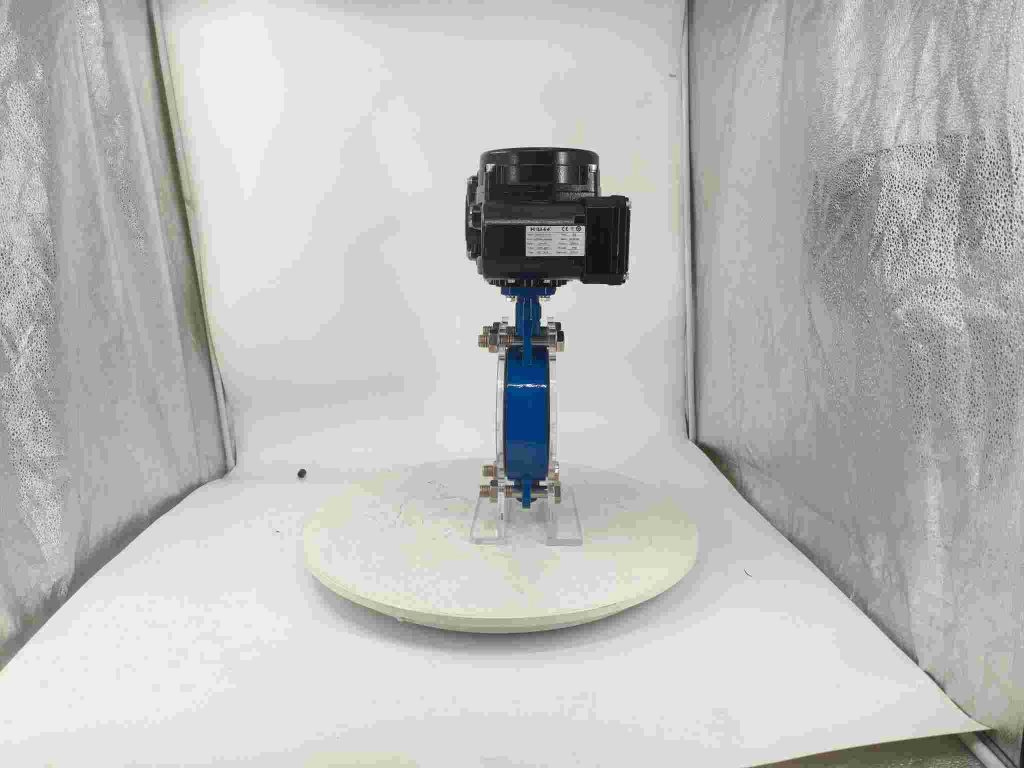

A damper actuator is a device that controls the opening and closing of dampers, which are used to regulate airflow in HVAC (Heating, Ventilation, and Air Conditioning) systems, industrial ventilation systems, or other processes that involve the movement of gases. These actuators play a crucial role in ensuring the proper functioning of ventilation systems, particularly in hazardous environments where the risk of explosion exists. An explosion-proof damper actuator is specifically engineered to prevent the ignition of flammable gases or dust in explosive atmospheres. The actuator is housed in a protective enclosure that is capable of withstanding internal pressure and containing any potential explosion. It is designed to function reliably even in harsh, dangerous conditions, making it a key component in systems where safety is paramount.