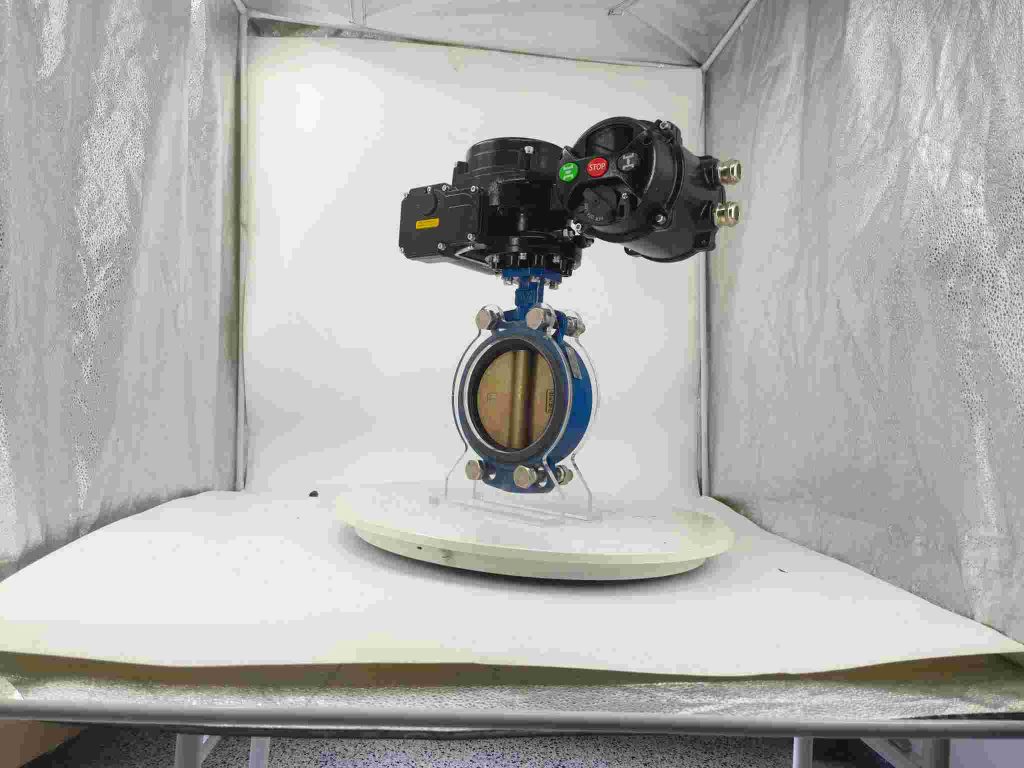

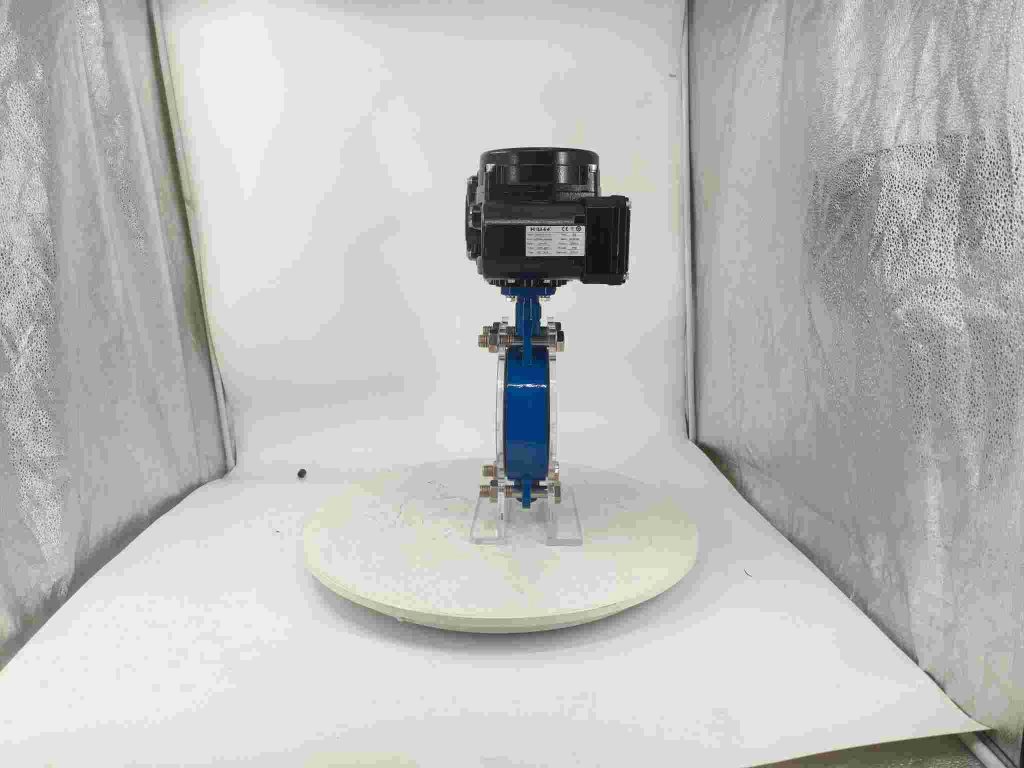

Electric ball valves have become integral components in various industries, ranging from water treatment to oil and gas. These valves, known for their reliability and precision in controlling fluid flow, are often produced by Original Equipment Manufacturers (OEMs) specializing in electric ball valve technology. This article delves into the significance of electric ball valve OEM manufacturers, their processes, and the advantages they bring to the market.

Understanding Electric Ball Valves

Electric ball valves utilize an electric actuator to control the opening and closing of the valve. The ball, featuring a hole through its center, rotates to either allow or restrict flow. This mechanism ensures quick operation and minimal pressure drop, making electric ball valves an ideal choice for automated systems requiring precise flow control. The Role of OEM Manufacturers Electric ball valve OEM manufacturers design and produce valves tailored to specific customer requirements. They play a crucial role in ensuring that these components meet industry standards and customer specifications. The customization offered by OEMs allows businesses to integrate electric ball valves seamlessly into their existing systems.