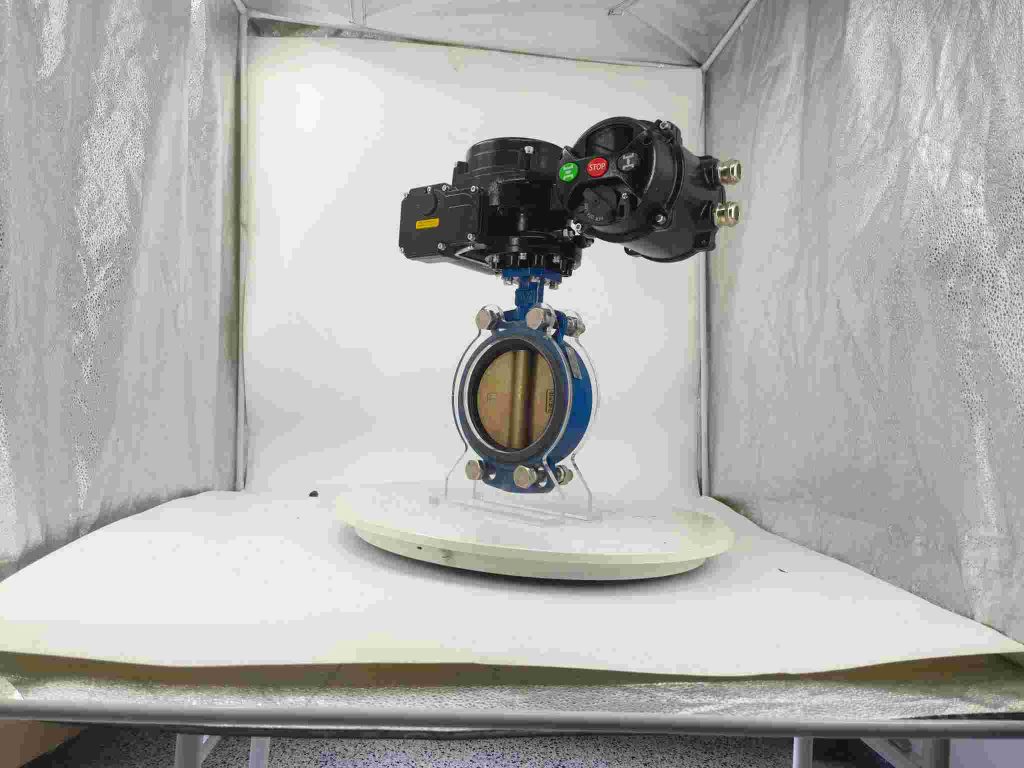

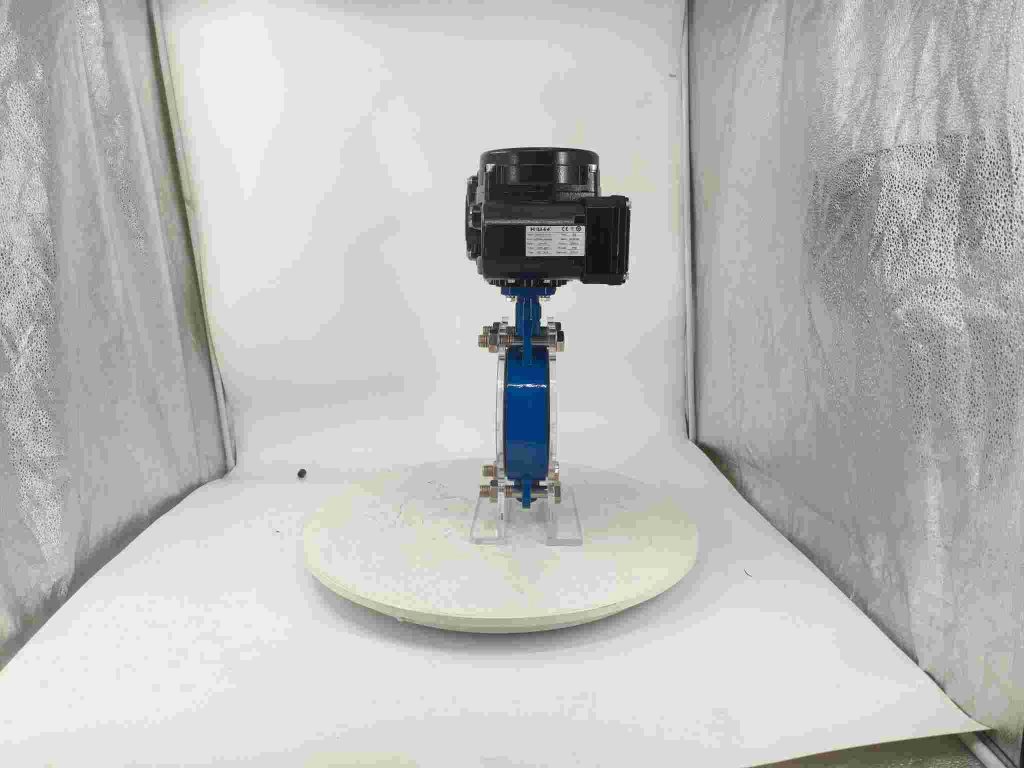

In today’s rapidly advancing industrial landscape, the need for efficient, reliable, and automated fluid control systems has never been greater. Among the key components driving this demand is the electric globe valve, a critical piece of equipment used across a wide range of industries for regulating the flow of fluids. As industries look to optimize their operations, the role of an Electric Globe Valve OEM (Original Equipment Manufacturer) becomes increasingly vital in delivering tailored, high-quality solutions.

What is an Electric Globe Valve?

An electric globe valve is a type of valve that uses an electric actuator to control the flow of fluids through a piping system. Unlike manual globe valves, which rely on mechanical manipulation, electric globe valves are powered by electric motors that move the valve’s internal components, such as the plug or disc, to adjust flow rates automatically. This makes electric globe valves essential in systems where precise flow control and automation are necessary, such as in heating, ventilation, and air conditioning (HVAC), chemical processing, water treatment, and oil & gas industries. The electric actuator typically includes a motor that is connected to a control system, allowing for remote operation, often via a central command center. This type of valve offers a significant advantage in terms of ease of use, efficiency, and safety, especially in complex systems that require continuous, real-time adjustments.