In the realm of industrial safety, the Explosion-proof Power off Reset Valve stands as a testament to technological advancements in preventing accidents in potentially explosive environments. This valve, with its unique combination of safety features and automation, has revolutionized the way we approach safety in industries dealing with flammable substances.

The Explosion-proof Power off Reset Valve is designed to mitigate the risks associated with electrical malfunctions or other emergencies that could lead to explosions. Its primary function is to automatically disconnect the power supply and reset the system in case of any abnormalities. This swift action prevents the ignition of flammable gases or vapors, thus averting potential disasters.

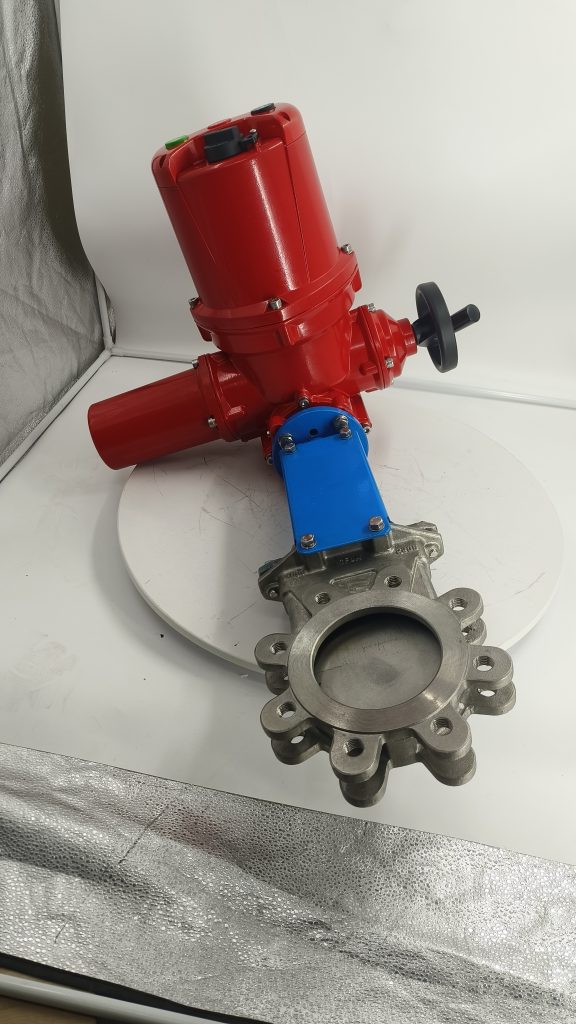

The valve’s explosion-proof design ensures its reliability even in the harshest industrial environments. It is constructed using materials that can withstand high temperatures and pressures, while also resisting corrosion and other forms of degradation. This durability ensures that the valve remains operational even under extreme conditions, providing a constant layer of protection for workers and equipment. Moreover, the Explosion-proof Power off Reset Valve incorporates advanced automation technology that allows it to respond quickly and accurately to any changes in the system. Sensors monitor the operating conditions continuously, and in case of any deviations from the norm, the valve springs into action, cutting off the power supply and initiating the reset process. This automation greatly reduces the need for manual intervention, minimizing the risk of human error and ensuring a consistent level of safety.