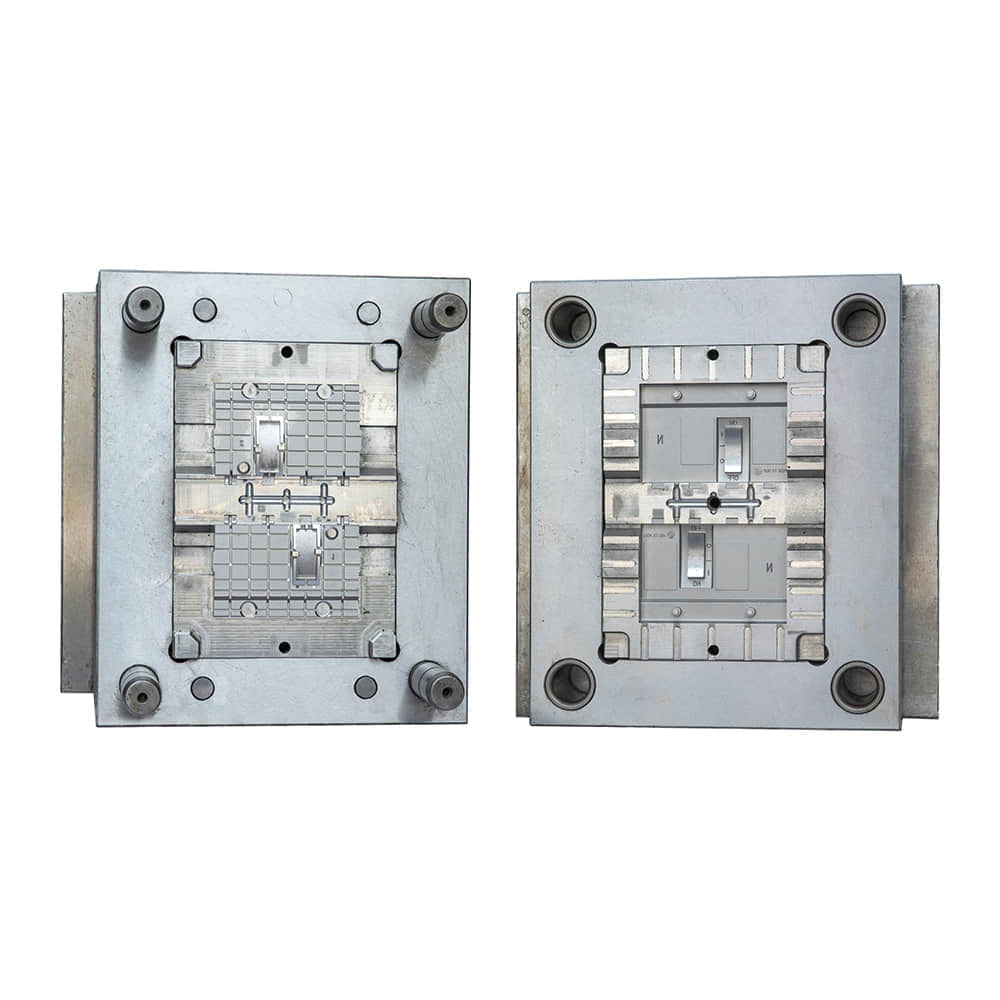

In the realm of electrical systems and distribution, ensuring safety, reliability, and efficiency is paramount. Molded Case Circuit Breakers (MCCBs) play a pivotal role in safeguarding electrical circuits and equipment from overcurrents and short circuits. Among the crucial components that contribute to the functionality and protection of MCCBs are the base cover parts. These components are designed and manufactured by specialized MCCB base cover parts manufacturers, who play a vital role in upholding the integrity of electrical systems.

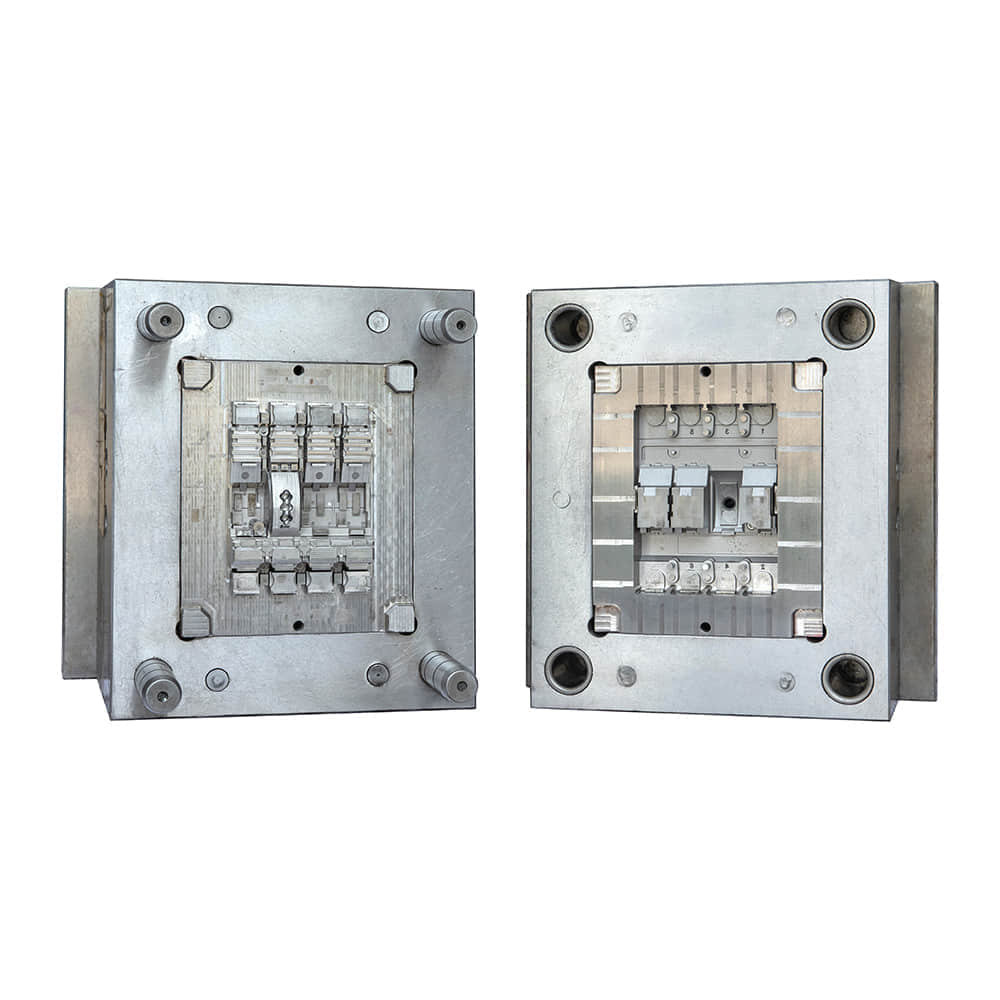

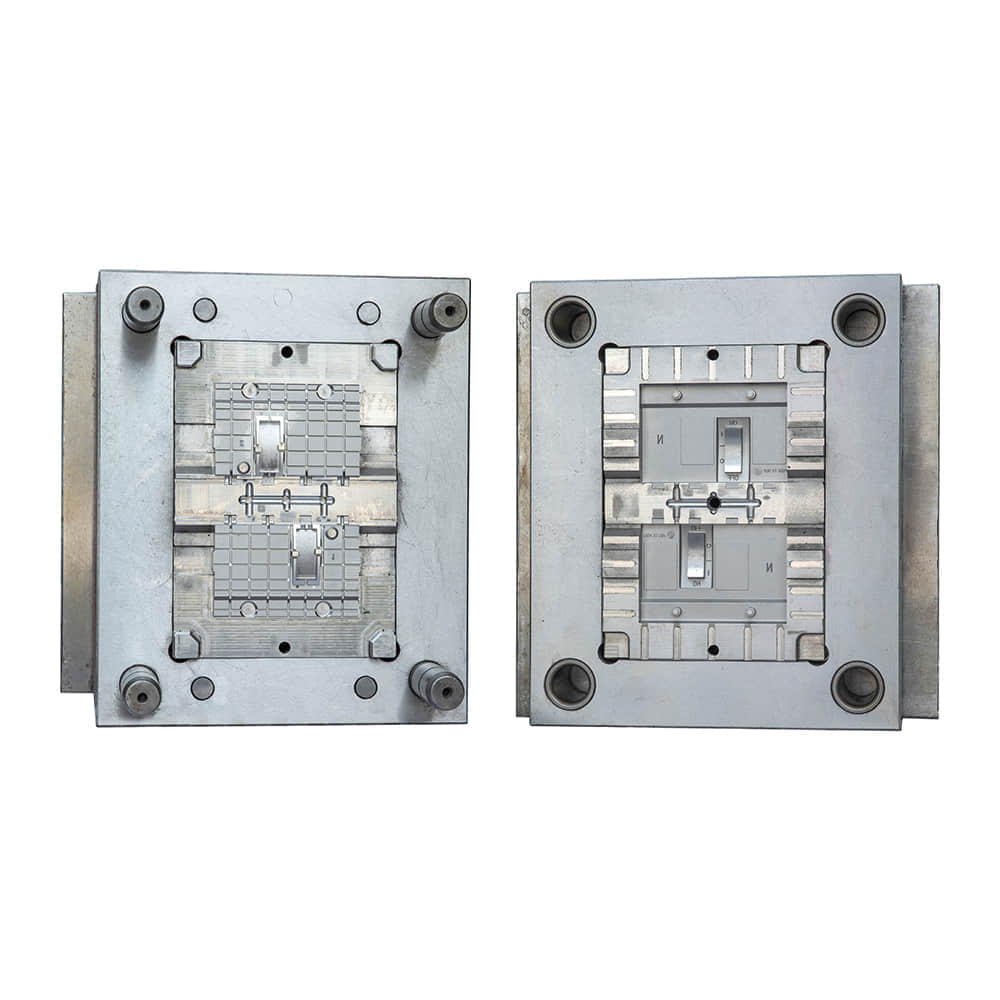

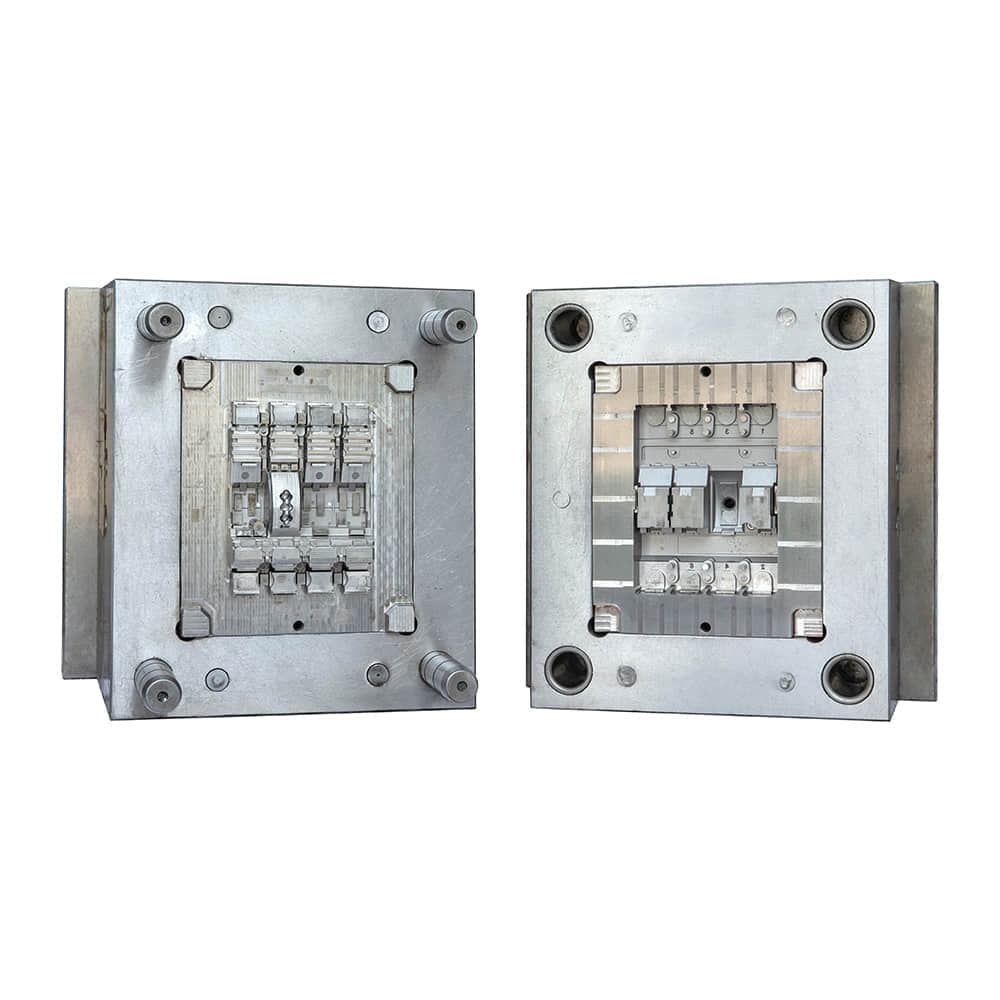

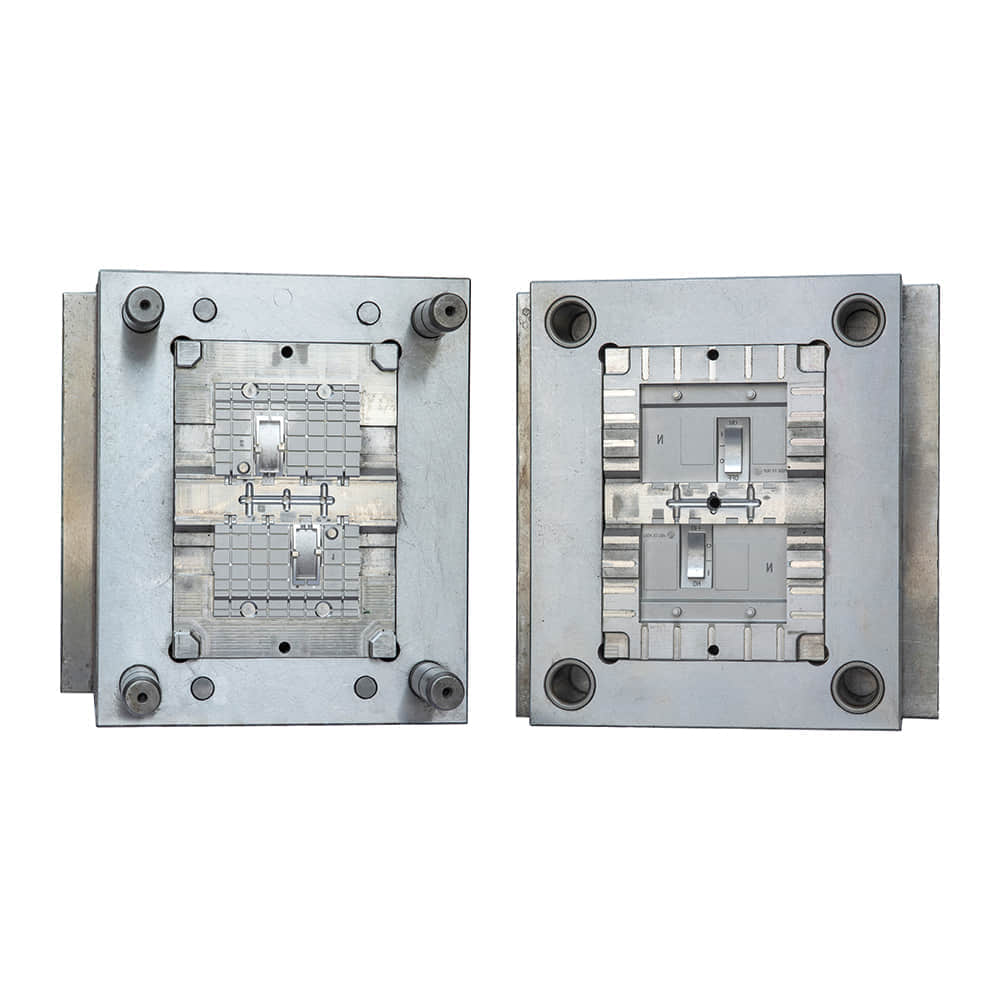

MCCB base cover parts manufacturers are dedicated to producing high-quality components that meet the stringent demands of modern electrical infrastructure. These components, often crafted from robust materials like thermoplastics or thermosetting plastics, provide mechanical support, insulation, and protection to the critical components within the MCCB assembly.

One of the primary functions of the base cover parts is to enclose and shield the internal components of the MCCB. This protection not only prevents physical tampering but also guards the components against environmental factors like dust, moisture, and contaminants. Manufacturers utilize advanced engineering techniques to ensure that the base covers are tightly sealed, maintaining the MCCB’s reliability even in challenging conditions. Safety is of utmost concern in electrical systems, and MCCB base cover parts manufacturers take this responsibility seriously. The base cover components are designed to provide an extra layer of protection against accidental contact with live parts, reducing the risk of electric shocks and ensuring the safety of maintenance personnel and end-users. The use of flame-retardant materials adds an additional safety measure, minimizing the potential for fire hazards. Reliability is another critical aspect addressed by MCCB base cover parts manufacturers. By adhering to strict quality control procedures and utilizing durable materials, these manufacturers create base cover parts that can withstand the rigors of long-term operation. This reliability ensures that the MCCBs maintain their performance over time, contributing to the overall stability of the electrical systems they protect. Customization is often a key feature offered by MCCB base cover parts manufacturers. Electrical systems can vary widely in terms of design and application. As a result, these manufacturers offer a range of base cover designs, sizes, and features to accommodate diverse requirements. This adaptability not only ensures proper fit and integration but also enhances the visual appeal of the MCCB assemblies. In a rapidly evolving technological landscape, MCCB base cover parts manufacturers also keep pace with innovation. They stay updated with the latest industry trends, regulations, and standards to continually improve their designs. Integration of smart technologies, such as sensors for monitoring and diagnostics, is becoming more prevalent in MCCB base cover parts, further contributing to the efficiency and functionality of electrical systems. Collaboration between MCCB manufacturers and base cover parts manufacturers is crucial for seamless integration and optimal performance. Engineers and designers from both sides work together to ensure that the base cover parts align perfectly with the MCCB design, allowing for smooth assembly and optimal protection. This partnership ultimately benefits the end-users by providing MCCBs that are not only safe and reliable but also easy to install and maintain. In conclusion, MCCB base cover parts manufacturers play a pivotal role in the realm of electrical safety and distribution. Through their commitment to quality, safety, and innovation, they provide essential components that enhance the reliability and functionality of MCCBs. These components not only protect the internal circuitry but also contribute to the overall efficiency and longevity of electrical systems. As technology continues to advance, MCCB base cover parts manufacturers will undoubtedly remain at the forefront of shaping safer and more reliable electrical infrastructures.