In the world of industrial manufacturing, precision and durability are paramount. Molded case parts play a pivotal role in ensuring the longevity and functionality of various machines and equipment. These parts, manufactured by specialized companies known as molded case parts manufacturers, are the unsung heroes that keep industries running smoothly. In this article, we will explore the significance of molded case parts manufacturers and delve into the key aspects of their operations.

The Backbone of Industrial Machinery

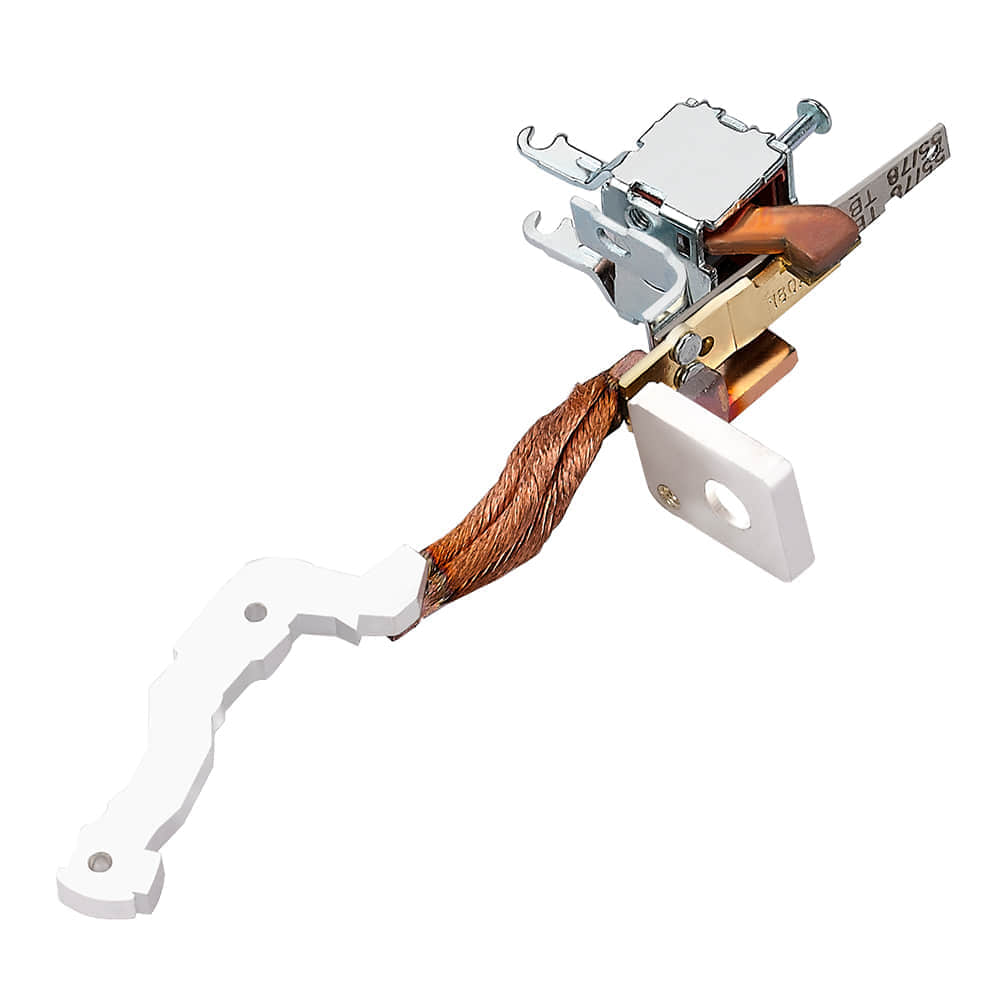

Molded case parts are crucial components used in a wide range of industries, including automotive, aerospace, electronics, and more. These parts are meticulously designed and manufactured to fit specific applications, ensuring seamless integration into various systems. Molded case parts manufacturers are the backbone of industrial machinery, providing essential components that facilitate the smooth operation of factories, transportation, and technology. Quality and Precision One of the defining characteristics of molded case parts manufacturers is their unwavering commitment to quality and precision. These companies invest heavily in state-of-the-art technology and employ skilled engineers and technicians to produce parts with unparalleled accuracy. Each component undergoes rigorous testing and quality control measures to meet the highest industry standards. Whether it’s a tiny connector or a complex housing, precision is the name of the game for these manufacturers. Customization and Versatility Molded case parts manufacturers understand that one size does not fit all. Industries have diverse needs, and customization is often essential. These manufacturers excel in tailoring their products to meet specific requirements. Whether it’s modifying the material composition, adjusting the dimensions, or incorporating unique features, they have the expertise to deliver precisely what their clients need. This versatility sets them apart as problem solvers in the industrial landscape. Material Expertise Choosing the right materials for molded case parts is crucial for their performance and longevity. Molded case parts manufacturers are well-versed in the properties of various materials, such as plastics, metals, and composites. They can recommend the ideal materials based on factors like strength, heat resistance, and electrical conductivity, ensuring that the final product excels in its intended application. Environmental Responsibility In today’s world, sustainability is a growing concern. Molded case parts manufacturers are increasingly embracing eco-friendly practices. Many of them use recyclable materials and employ energy-efficient manufacturing processes to reduce their carbon footprint. By doing so, they not only contribute to a healthier planet but also meet the sustainability demands of their clients. Global Reach and Supply Chain Management Molded case parts manufacturers often operate on a global scale, serving clients around the world. Managing a vast supply chain and ensuring timely delivery of parts is a complex endeavor. These manufacturers have perfected the art of logistics, leveraging technology and efficient distribution networks to meet their customers’ demands, no matter where they are located. Innovation and Research Staying at the forefront of technological advancements is imperative in the manufacturing industry. Molded case parts manufacturers invest in research and development to create cutting-edge solutions. Whether it’s developing new materials, refining manufacturing techniques, or enhancing product performance, innovation is a driving force behind their success. Conclusion Molded case parts manufacturers are the unsung heroes of the industrial world, providing essential components that keep industries running smoothly. Their commitment to quality, precision, customization, and sustainability sets them apart as indispensable partners for various sectors. With their expertise and dedication to innovation, these manufacturers continue to shape the future of industrial manufacturing, ensuring that machinery and equipment perform at their best, day in and day out.