Molded Case Circuit Breakers (MCCBs) play a crucial role in electrical systems, safeguarding them from overcurrents and short circuits. As technology advances, so does the manufacturing process of these essential components. In this article, we delve into the innovations that have shaped the landscape of MCCB manufacturing, ensuring safety, efficiency, and reliability in electrical distribution networks.

Evolution of MCCBs: From Conventional to Advanced Manufacturing

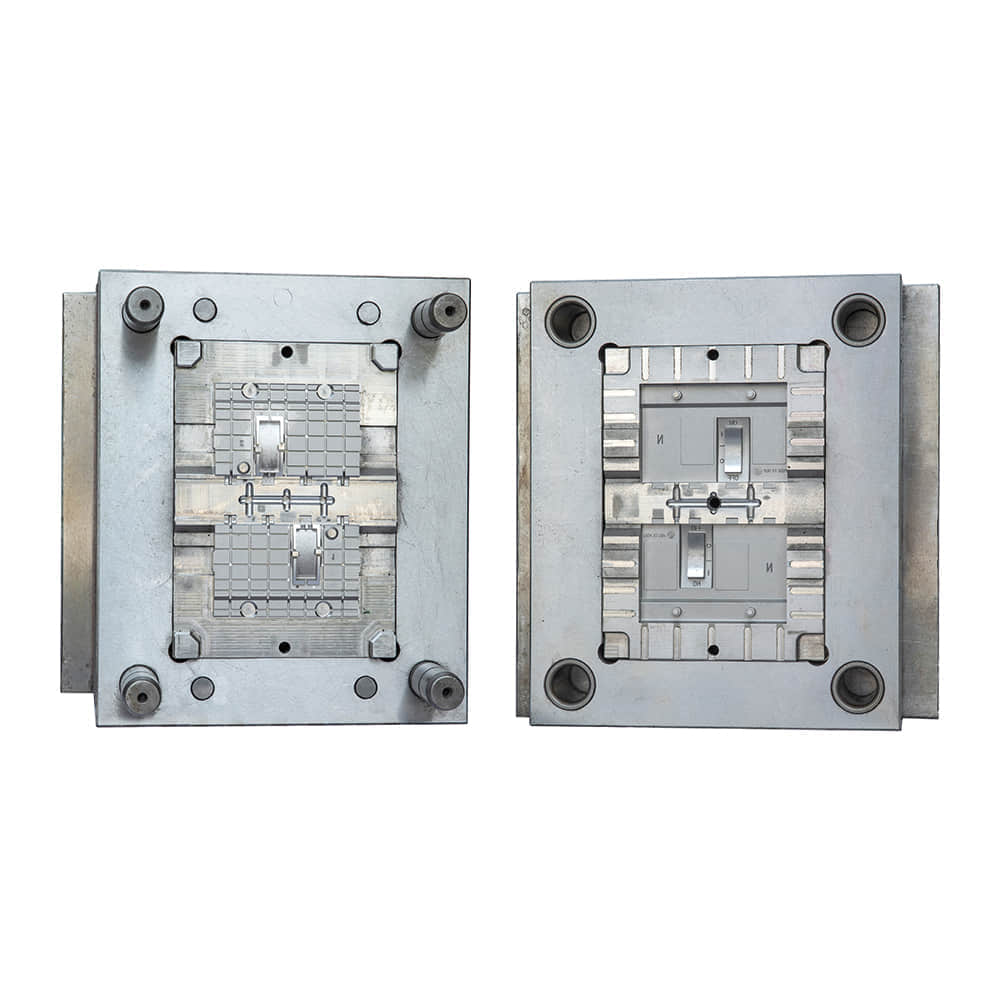

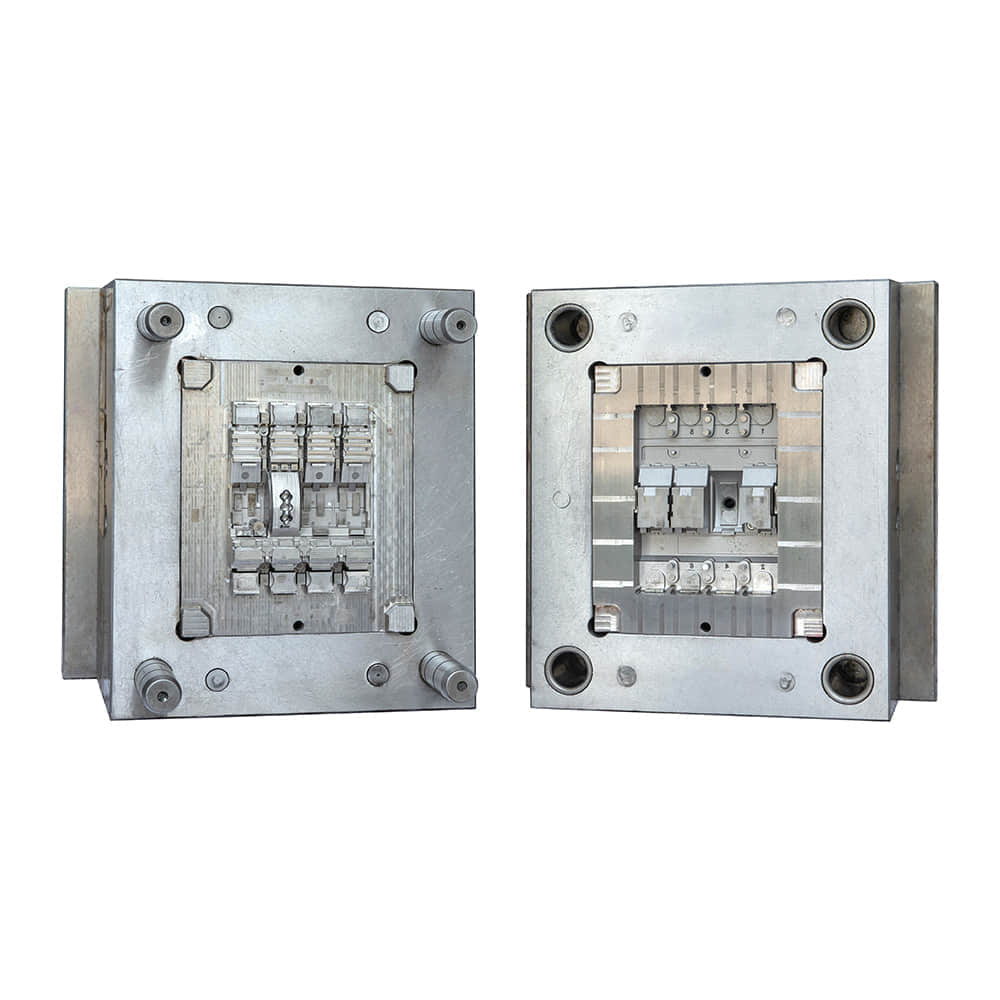

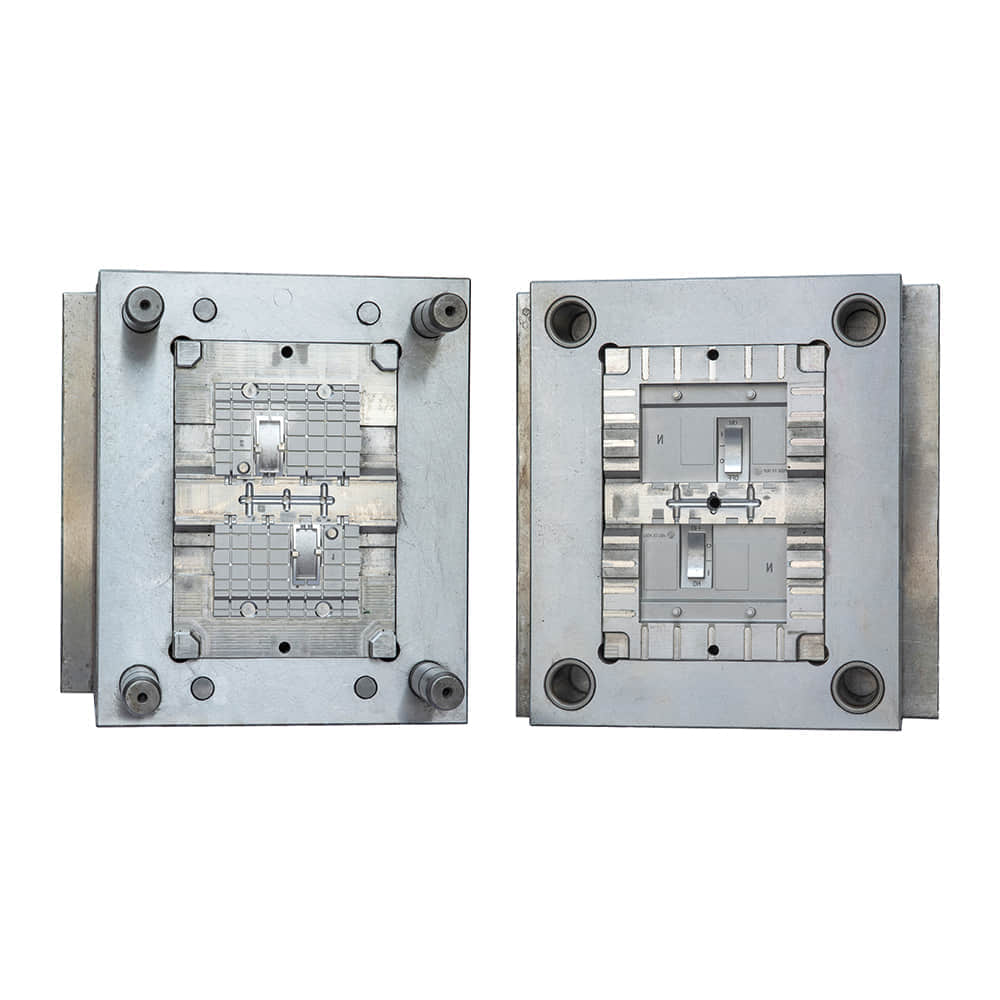

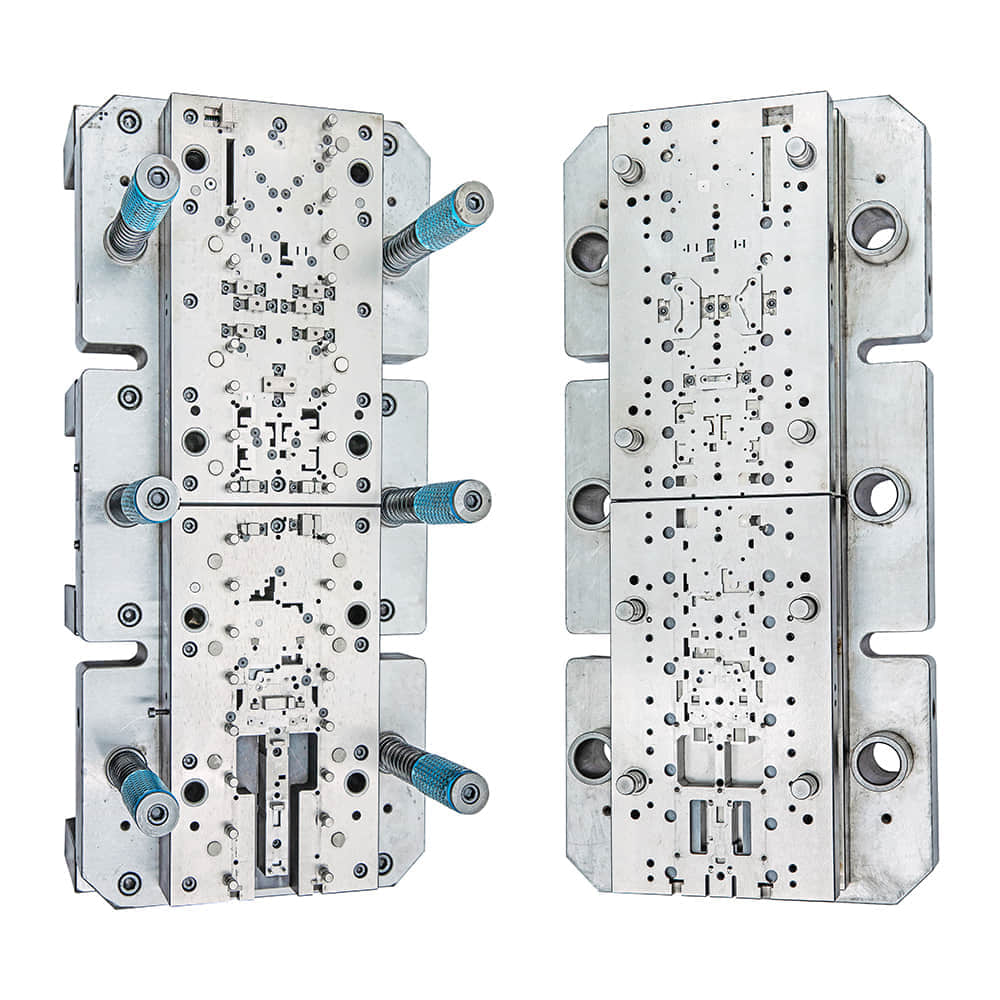

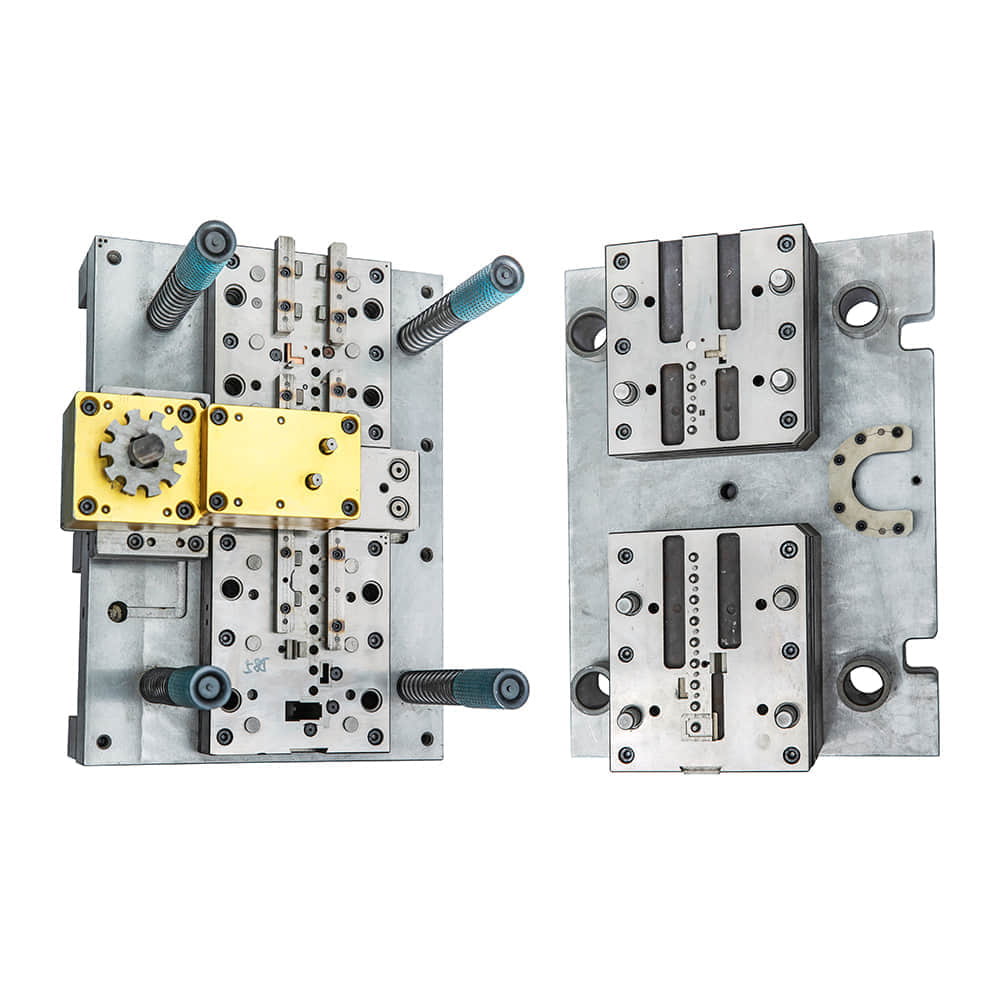

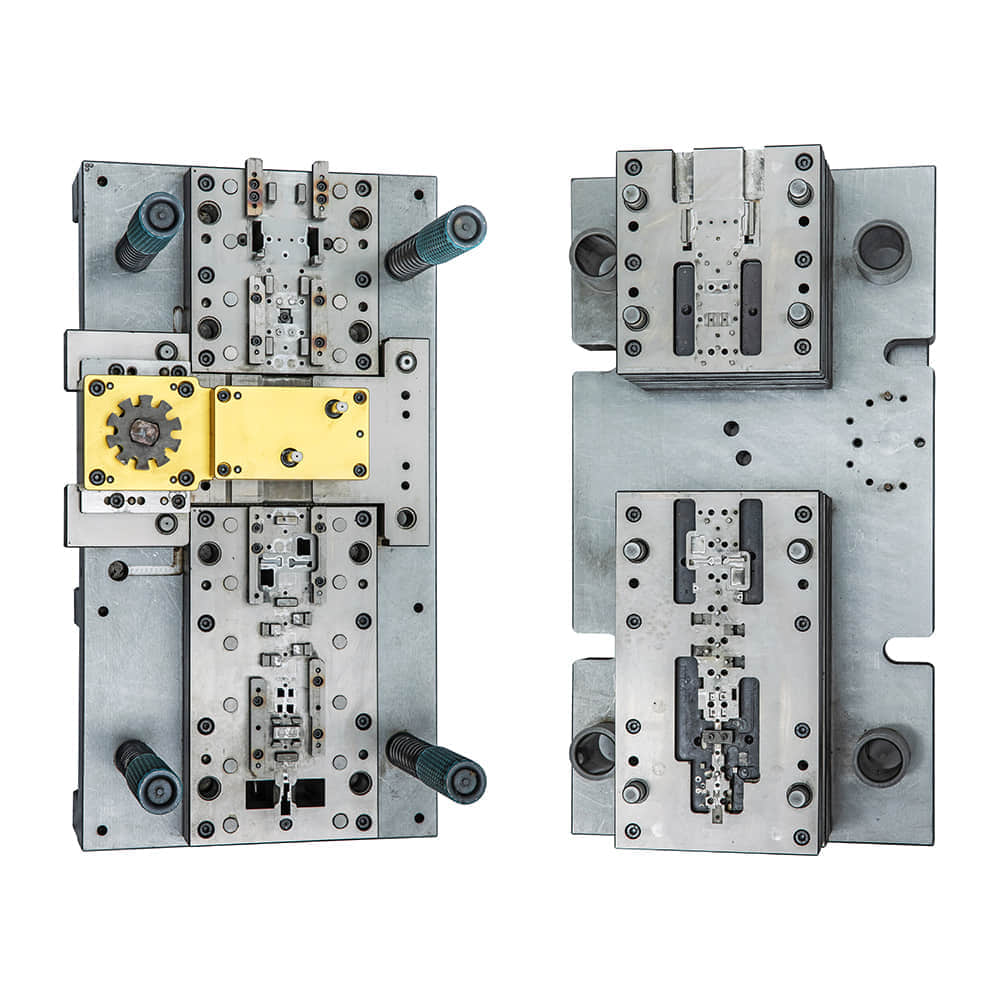

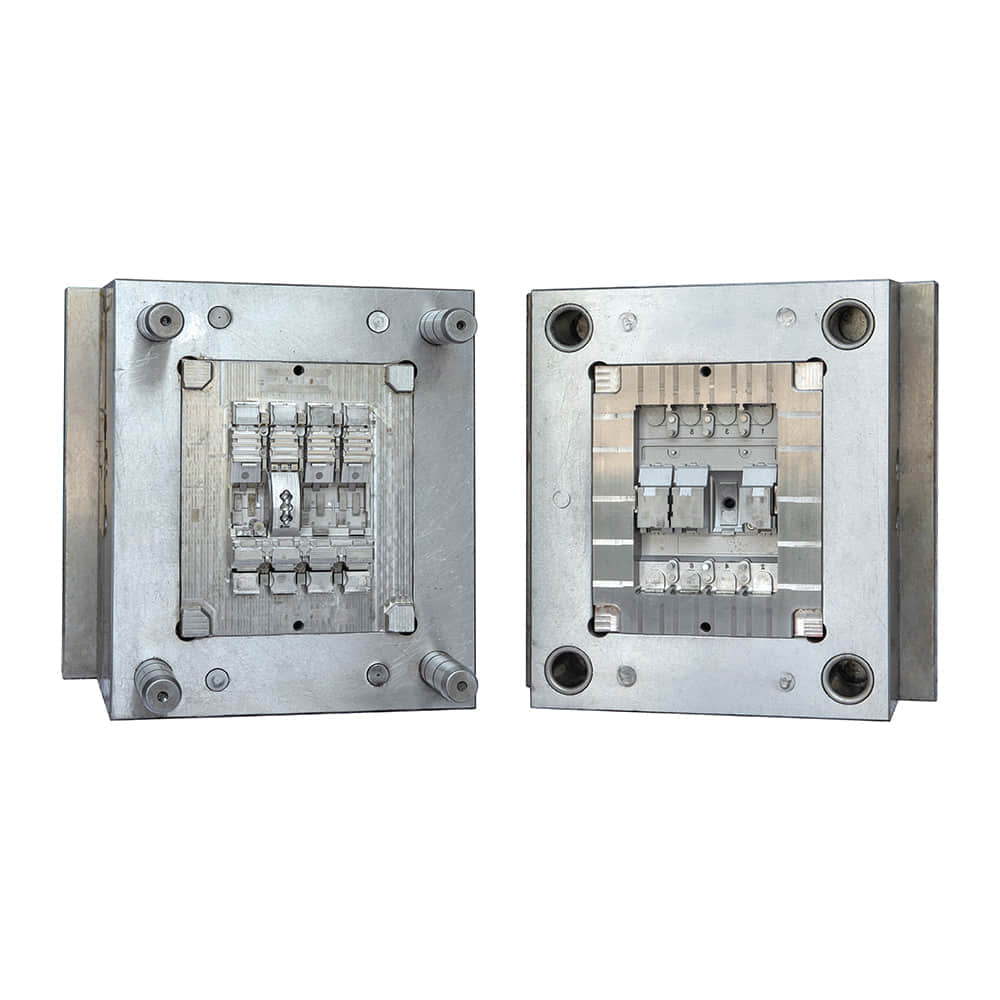

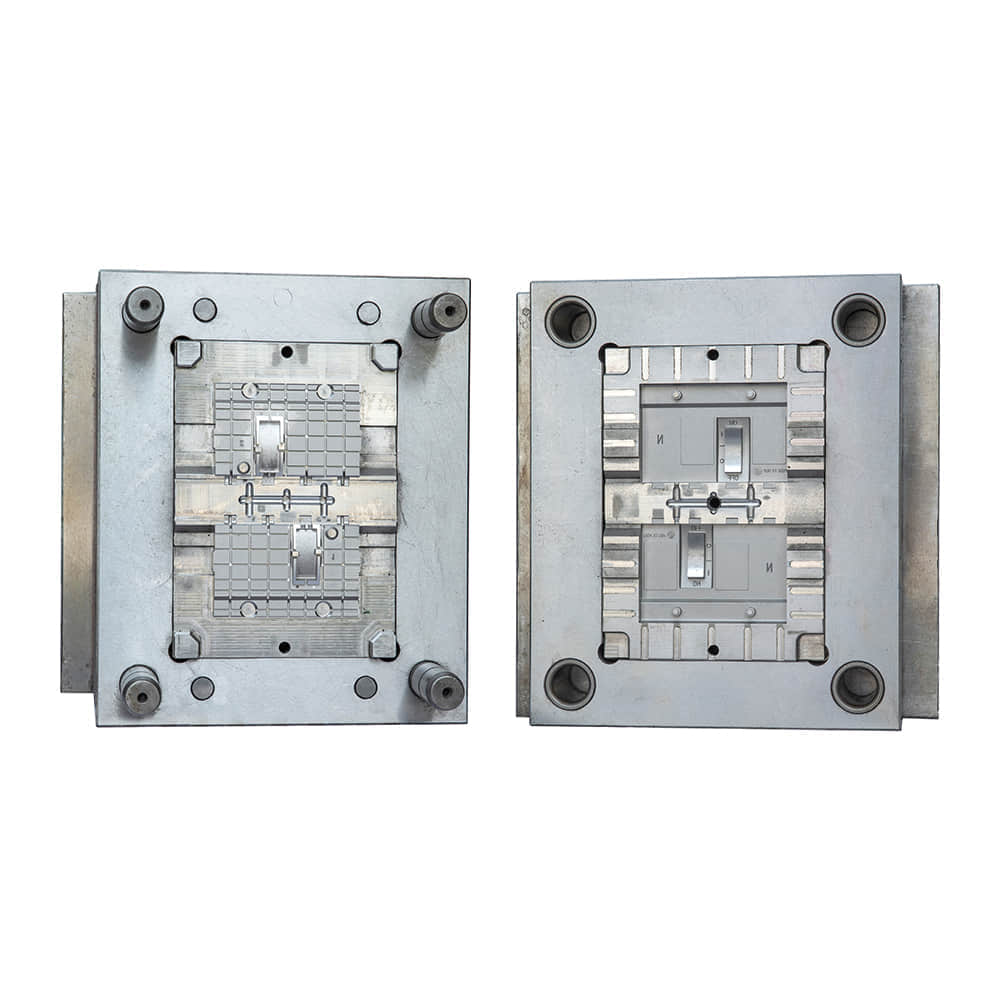

Traditionally, MCCBs were manufactured using labor-intensive processes, often involving manual assembly and testing. However, the demand for increased performance, enhanced features, and higher reliability prompted a shift towards automated manufacturing techniques. Modern MCCB manufacturing facilities now utilize cutting-edge technologies such as robotics, computer-aided design (CAD), and advanced quality control systems. Precision Engineering and Design One of the key advancements in MCCB manufacturing is precision engineering. CAD software allows engineers to design intricate components with meticulous accuracy. This results in better-fitting parts, improved performance, and reduced energy losses within the breaker. Moreover, computer simulations enable manufacturers to assess various design iterations before selecting the optimal one for production. Smart Manufacturing and IoT Integration The rise of Industry 4.0 has influenced MCCB manufacturing significantly. Smart manufacturing techniques involve the integration of the Internet of Things (IoT) devices and sensors throughout the production process. These sensors monitor various parameters, such as temperature, pressure, and vibration, in real-time. This data is then analyzed to detect anomalies, predict maintenance needs, and optimize the manufacturing process for higher efficiency and quality. Materials Innovation The choice of materials has a direct impact on the performance and longevity of MCCBs. With advancements in material science, manufacturers now have access to lighter, more durable, and heat-resistant materials. These materials not only improve the MCCBs’ efficiency but also extend their operational lifespan, reducing the need for frequent replacements. Quality Control and Testing Ensuring the reliability of MCCBs is paramount. Advanced testing methods, including thermal imaging, X-ray inspection, and automated functional tests, guarantee that each MCCB leaving the production line meets the strictest quality standards. Manufacturers can identify potential defects early in the process, reducing the likelihood of faulty products reaching consumers. Environmental Considerations In today’s environmentally conscious world, sustainable manufacturing practices are gaining importance. Manufacturers of MCCBs are focusing on reducing energy consumption during production, optimizing material usage, and implementing recycling programs for end-of-life MCCBs. This approach not only minimizes the environmental impact but also aligns with the global push for a greener future. Customization and Flexibility Every electrical system is unique, and MCCBs must be tailored to suit various requirements. Advanced manufacturing allows for greater customization and flexibility in MCCB design and production. Manufacturers can swiftly adapt their processes to produce MCCBs with specific features, ratings, and sizes, meeting the diverse needs of customers across industries. Global Outreach and Accessibility Innovations in MCCB manufacturing have not only enhanced their quality but also increased their accessibility on a global scale. As developing countries expand their electrical infrastructure, the availability of reliable MCCBs becomes crucial. Advanced manufacturing techniques enable manufacturers to produce high-quality MCCBs at a larger scale and more affordable costs, contributing to the electrification of remote and underserved areas. Conclusion The manufacturer of molded case circuit breakers has evolved significantly over the years, driven by technological advancements and the need for safer and more efficient electrical systems. From precision engineering and smart manufacturing to materials innovation and quality control, these innovations have revolutionized MCCB manufacturing. As our reliance on electricity continues to grow, these advancements ensure that our electrical distribution networks remain robust, resilient, and prepared for the future.