In today’s rapidly advancing world, electrical systems have become an indispensable part of our daily lives. From powering our homes to driving industrial processes, electricity plays a pivotal role. However, with great power comes great responsibility, and ensuring electrical safety is paramount. One innovative solution that has emerged to address this concern is the Molded Case Circuit Breaker (MCCB) with Residual Leakage Protection. In this article, we will delve into the significance of this technology and how it contributes to enhancing electrical safety.

Understanding the MCCB with Residual Leakage Protection

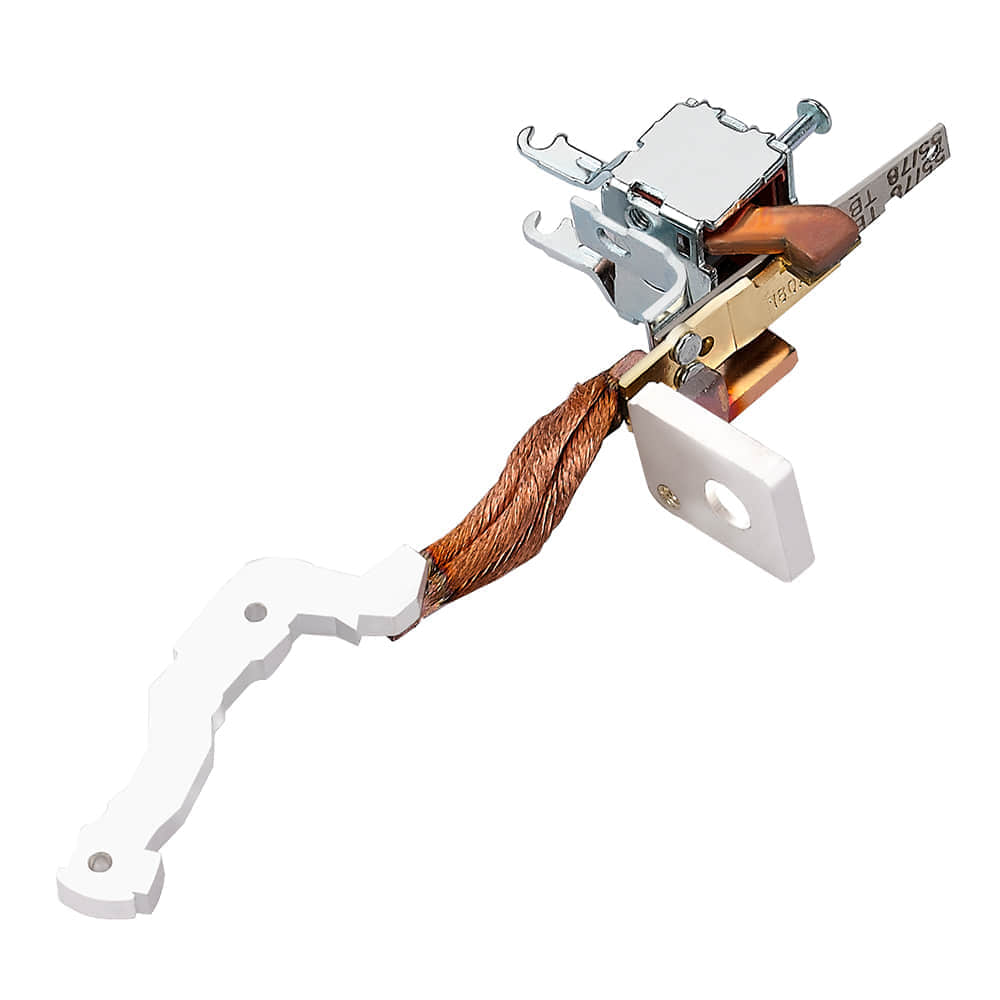

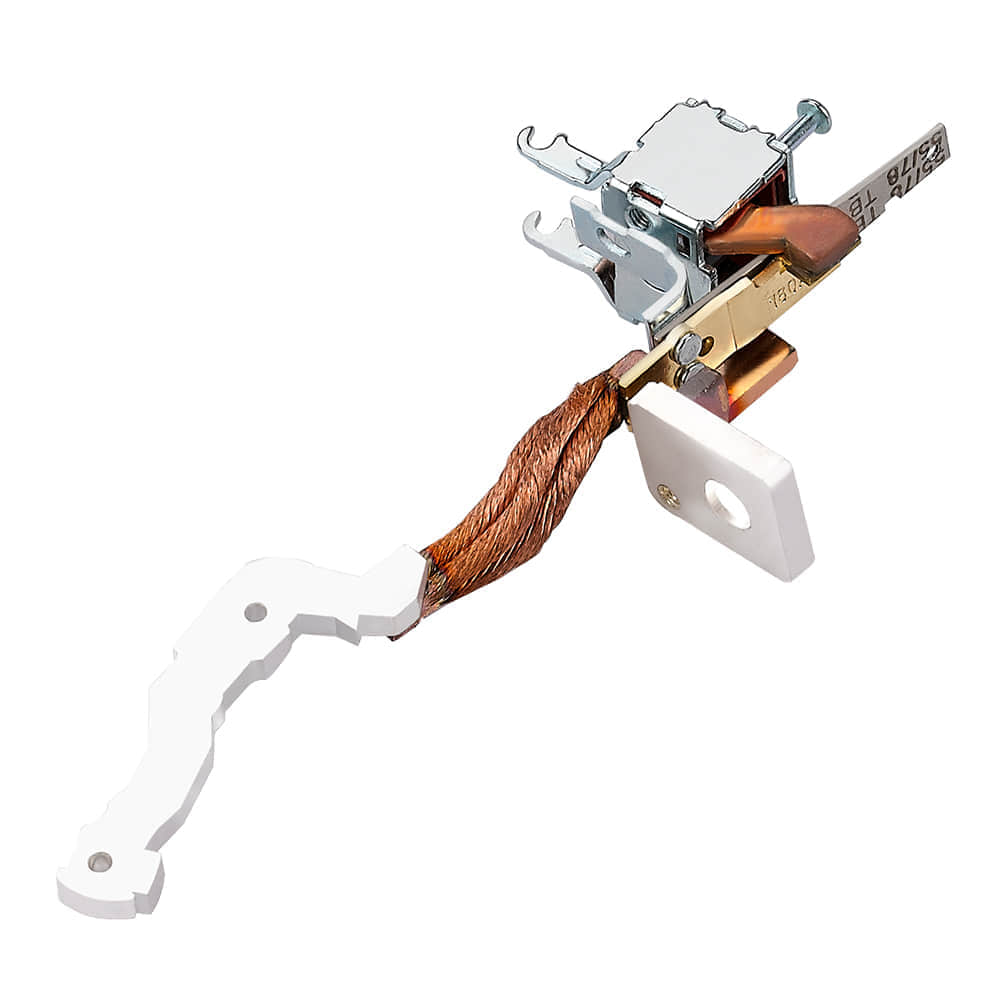

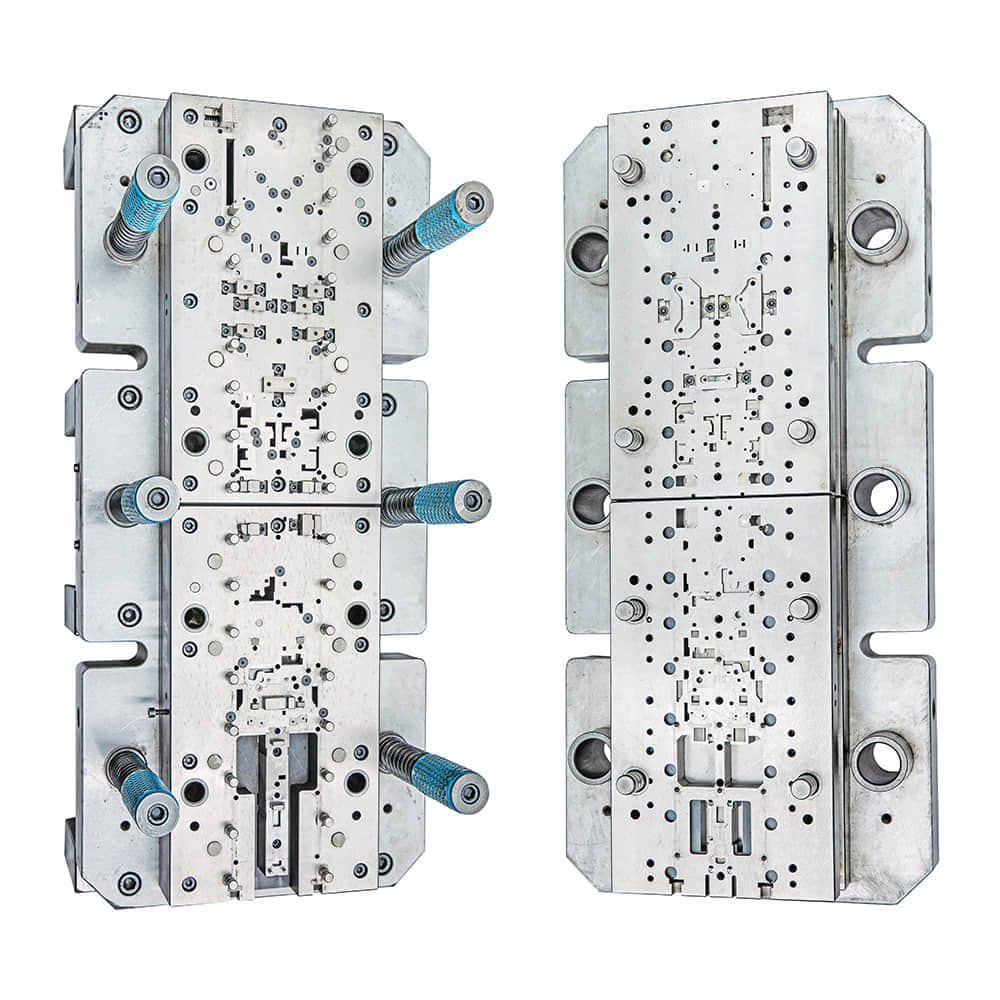

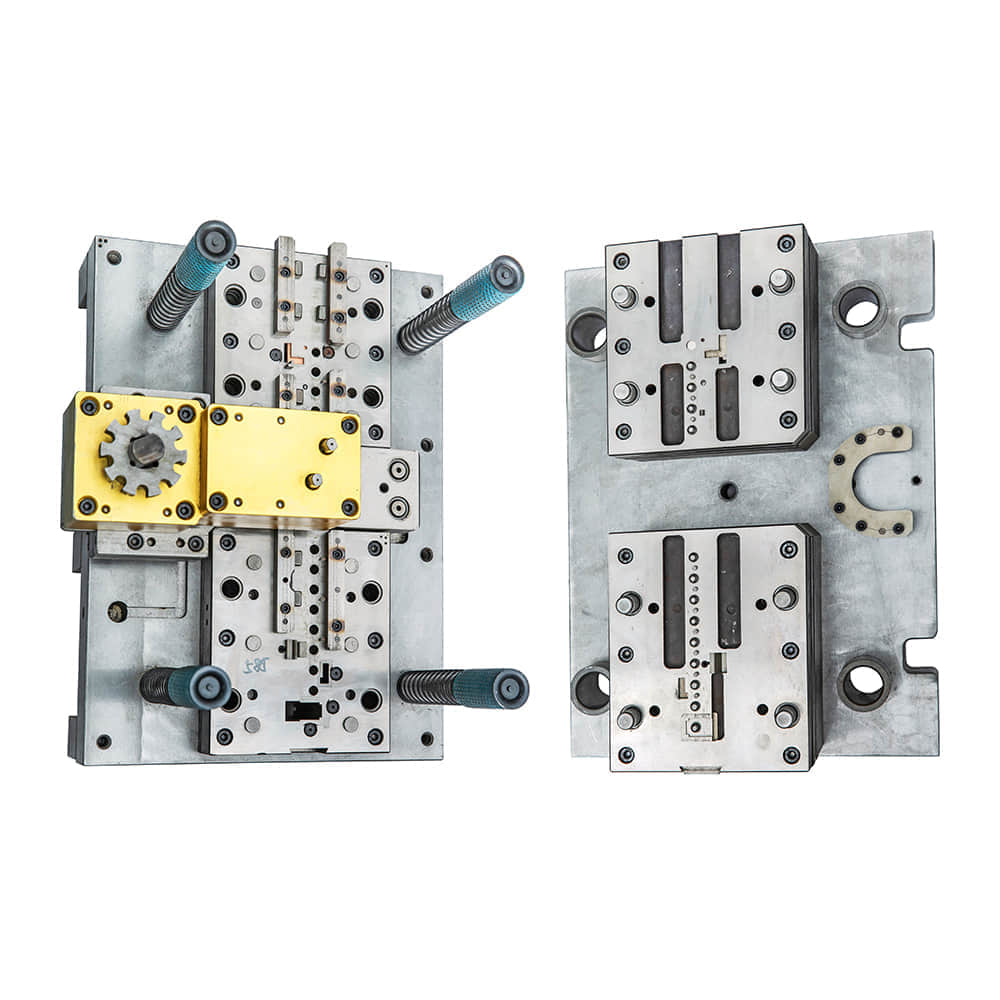

MCCBs, at their core, are electromechanical devices designed to protect electrical circuits from overloads and short circuits. They are commonly used in both residential and industrial settings. These circuit breakers automatically open the circuit when they detect an abnormal condition, thus preventing damage to the electrical system and reducing the risk of electrical fires. What sets the MCCB with Residual Leakage Protection apart is its ability to detect ground faults or residual currents that may occur due to insulation breakdown or contact with water. This technology goes beyond conventional MCCBs, adding an extra layer of protection by monitoring the difference between incoming and outgoing currents. When an imbalance is detected, indicating a leakage of current to ground, the MCCB with Residual Leakage Protection trips the circuit, effectively cutting off the power supply. Key Advantages Enhanced Safety: The primary advantage of MCCBs with residual leakage protection is the heightened level of safety they provide. Traditional MCCBs may not detect leakage to ground, which can be a precursor to dangerous electrical shocks. By swiftly interrupting the circuit upon detecting ground faults, this technology significantly reduces the risk of electrical accidents. Protection Against Fire: Ground faults are a common cause of electrical fires. MCCBs with residual leakage protection play a crucial role in preventing such incidents by promptly disconnecting the power supply in case of a fault. Versatility: These devices are adaptable and can be used in various applications, from protecting household circuits to safeguarding industrial machinery. Their versatility makes them a valuable asset in ensuring electrical safety across different sectors. Compliance with Standards: MCCBs with residual leakage protection are often designed to meet stringent safety standards and regulations, ensuring that installations are in compliance with electrical safety codes. Remote Monitoring: Some advanced MCCBs with residual leakage protection offer remote monitoring capabilities, allowing users to keep track of their electrical systems’ status and respond to issues promptly, even from a distance. Applications The applications of MCCBs with residual leakage protection are diverse: Residential Use: In homes, these devices protect occupants from electrical shocks and reduce the risk of fires in the event of a ground fault. Commercial Buildings: They are used in offices and commercial spaces to safeguard electrical circuits, ensuring the uninterrupted operation of critical equipment. Industrial Facilities: MCCBs with residual leakage protection are essential in industries where electrical faults can lead to costly downtime and damage to machinery. Renewable Energy: They play a crucial role in the renewable energy sector, safeguarding solar panels and wind turbines from electrical faults. Construction Sites: These devices are employed at construction sites to protect workers and equipment from electrical hazards. Conclusion In an age where electricity powers our world, the safety of electrical systems is of paramount importance. The MCCB with Residual Leakage Protection stands as a testament to the continuous innovation in electrical safety technology. By detecting ground faults and acting swiftly to disconnect power, it not only prevents accidents but also safeguards property and investments. As we continue to rely on electricity for an ever-expanding range of applications, embracing such advancements in electrical safety becomes not just a choice but a necessity for a safer and more secure future.