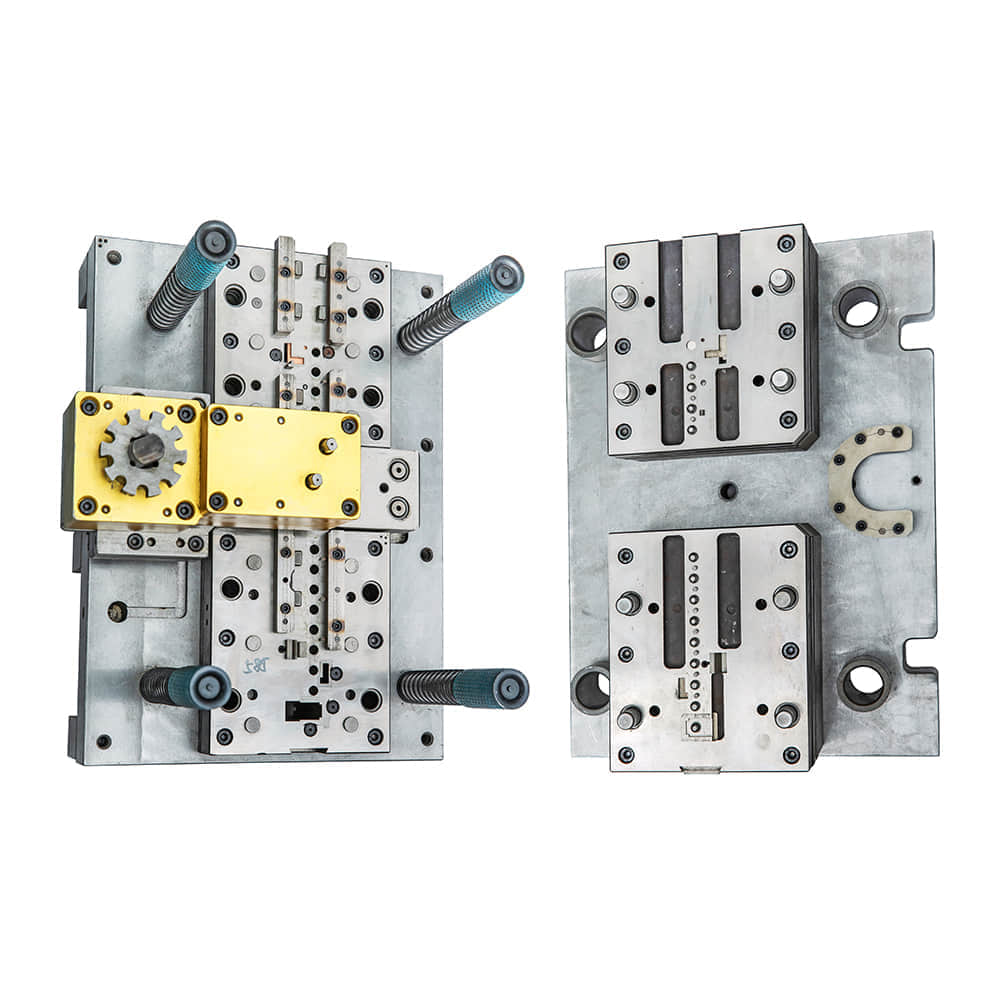

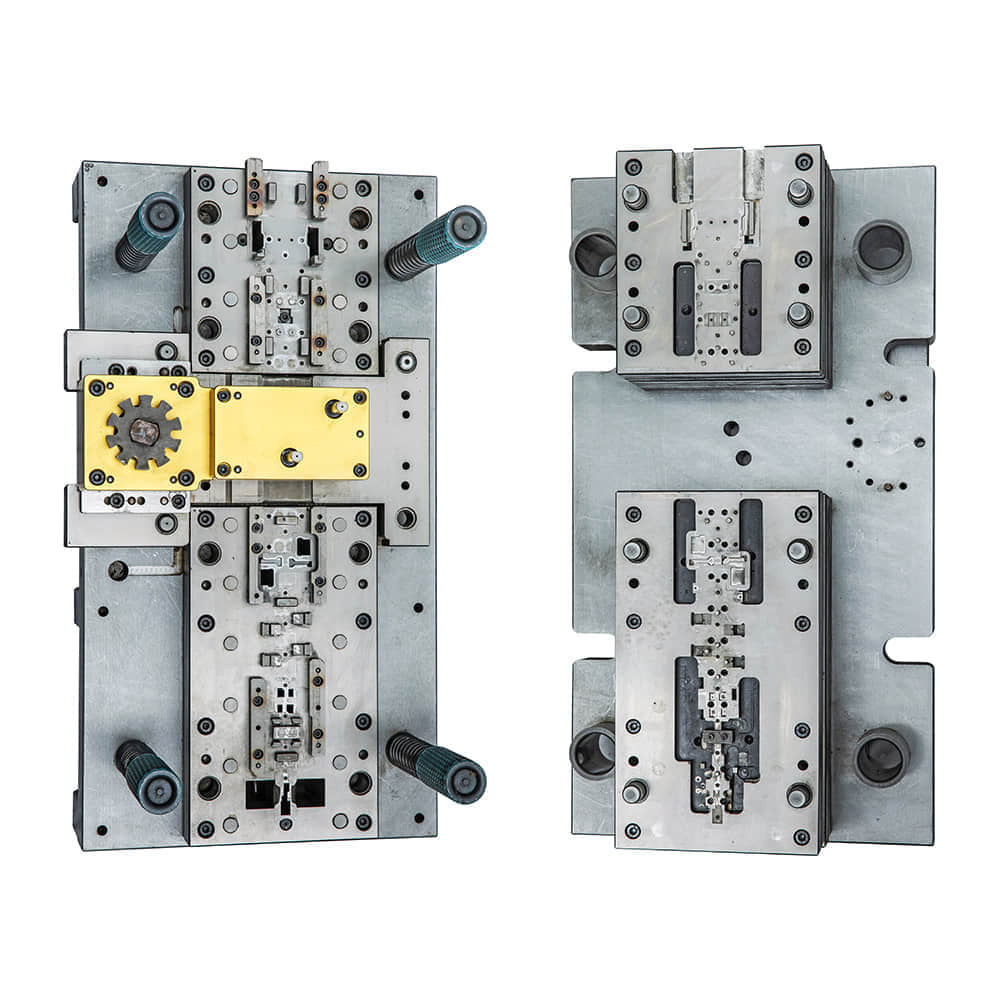

China Molded Case Parts Manufacturer has emerged as a prominent player in the manufacturing landscape, setting new standards of excellence, precision, and innovation in the industry. With a relentless commitment to quality and cutting-edge technology, this company has not only captured the domestic market but has also gained global recognition for its exceptional molded case parts.

Precision Engineering at its Finest

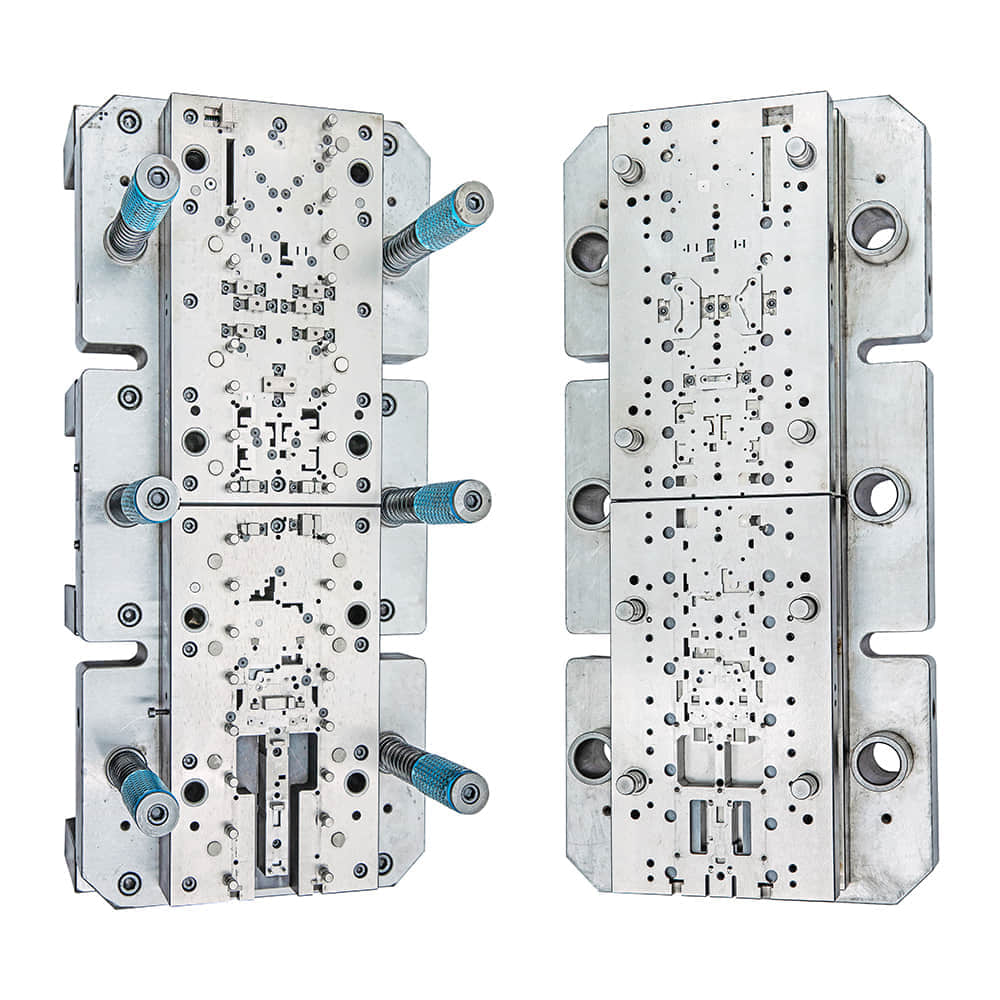

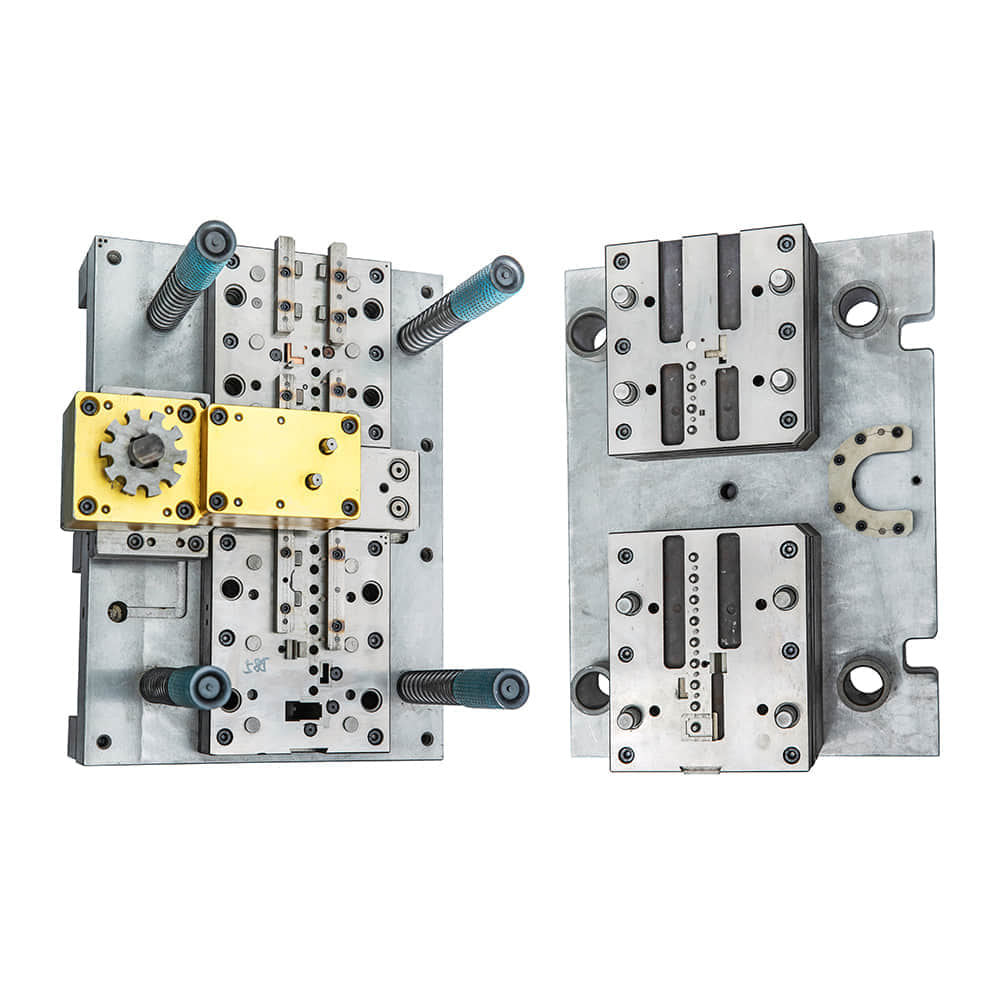

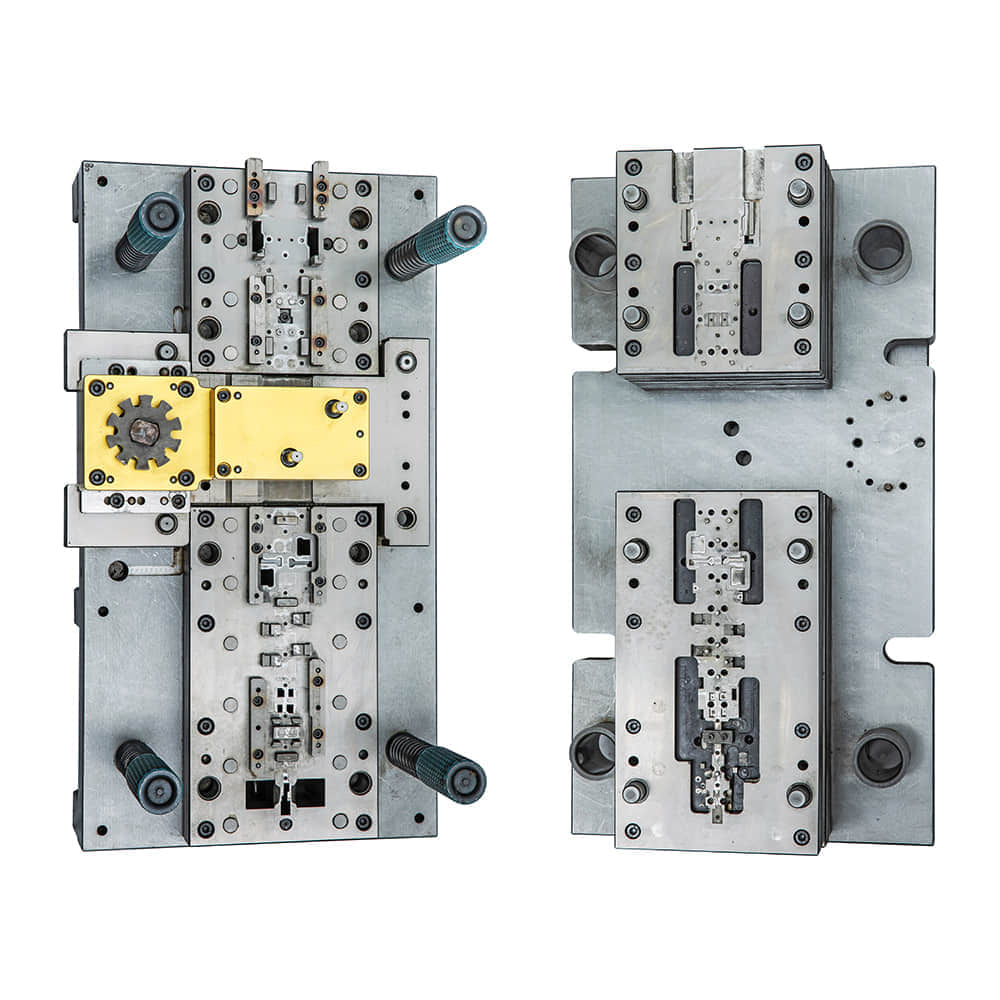

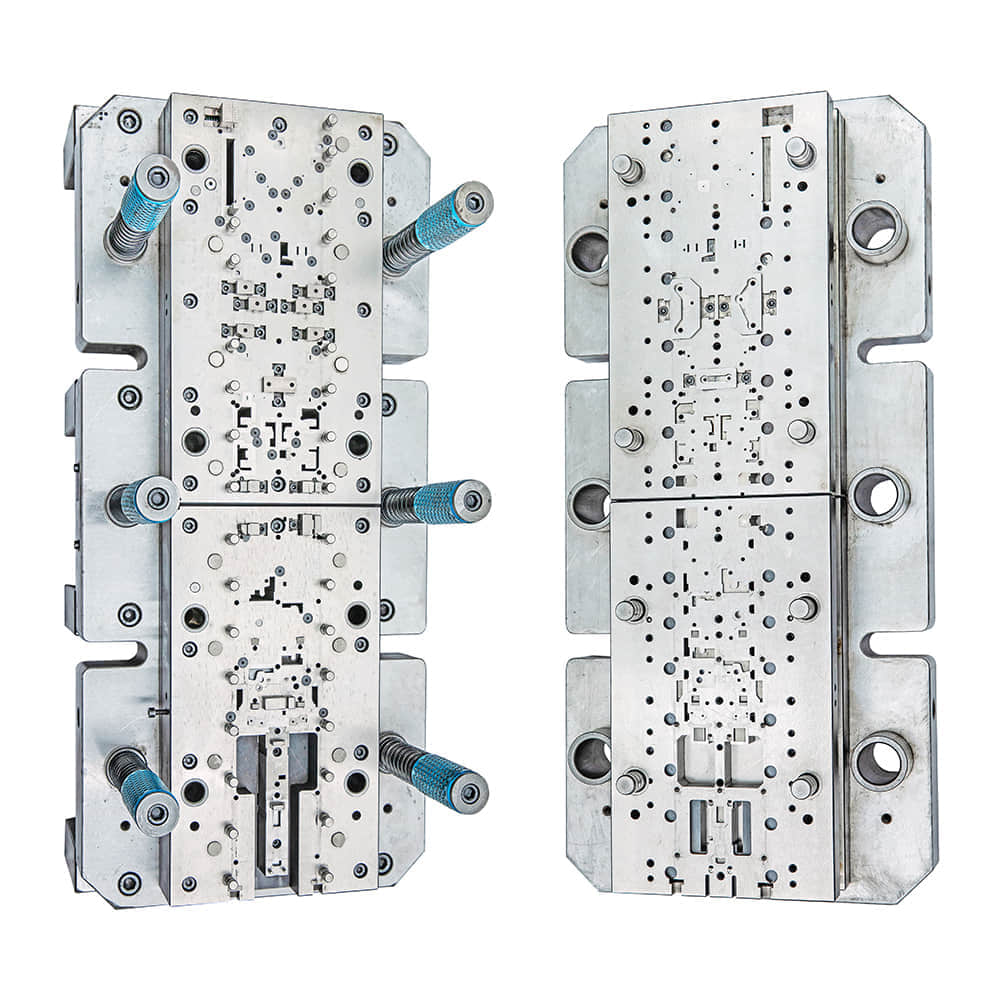

At the heart of China Molded Case Parts Manufacturer’s success lies its unwavering dedication to precision engineering. Every component produced by the company is a testament to the meticulous craftsmanship that goes into its creation. Leveraging state-of-the-art manufacturing techniques, the company ensures that each molded case part adheres to the strictest tolerances and quality standards. This commitment to precision has solidified the company’s reputation as a reliable partner for industries demanding uncompromised accuracy. Innovative Technological Integration In an ever-evolving manufacturing landscape, innovation is the key to staying ahead of the competition. China Molded Case Parts Manufacturer recognizes this imperative and has embraced technological innovation as a driving force behind its operations. The company has heavily invested in research and development, consistently exploring new materials, manufacturing processes, and design methodologies. This forward-thinking approach has not only resulted in more efficient production processes but has also led to the creation of parts with enhanced performance characteristics. Global Reach, Local Presence China Molded Case Parts Manufacturer has transcended its origins and established a global footprint. Its commitment to quality and innovation has resonated with clients worldwide, leading to the company’s parts being utilized in diverse applications across different industries. Despite its global reach, the company maintains a strong local presence, actively contributing to the development of the manufacturing ecosystem in China. Sustainable Practices In an era of heightened environmental consciousness, China Molded Case Parts Manufacturer stands out for its commitment to sustainability. The company has implemented eco-friendly practices throughout its operations, from sourcing materials to optimizing energy consumption in its manufacturing processes. By integrating sustainability into its core values, the company not only contributes to a greener planet but also sets an example for the manufacturing sector as a whole. Customer-Centric Approach One of the defining factors behind China Molded Case Parts Manufacturer’s success is its customer-centric approach. The company views its clients as partners, working closely with them to understand their unique needs and challenges. This collaborative approach enables the company to tailor its products to specific requirements, ensuring that each client receives solutions that align perfectly with their goals. Empowered Workforce Behind the scenes of China Molded Case Parts Manufacturer’s achievements is a dedicated and skilled workforce. The company recognizes the value of its employees and provides them with a conducive environment for growth and innovation. By nurturing talent and fostering a culture of continuous learning, the company ensures that its team remains at the forefront of industry trends and technological advancements. Conclusion China Molded Case Parts Manufacturer’s journey to becoming an industry leader has been marked by its unwavering commitment to precision, innovation, and customer satisfaction. Through its precision engineering, technological innovation, global outreach, sustainable practices, customer-centric approach, and empowered workforce, the company has set a remarkable example for the manufacturing sector. As the company continues to push the boundaries of what is possible, it is poised to shape the future of molded case parts manufacturing not only in China but around the world.