Molded Case Circuit Breakers: Safeguarding Your Electrical Systems

In our modern world, electricity is the lifeblood that powers our homes, businesses, and industries. With the ever-increasing demand for electrical power, ensuring the safety and reliability of electrical systems is paramount. One critical component that plays a pivotal role in this endeavor is the Molded Case Circuit Breaker (MCCB). In this article, we will explore what MCCBs are, how they work, and why they are indispensable in safeguarding electrical systems.

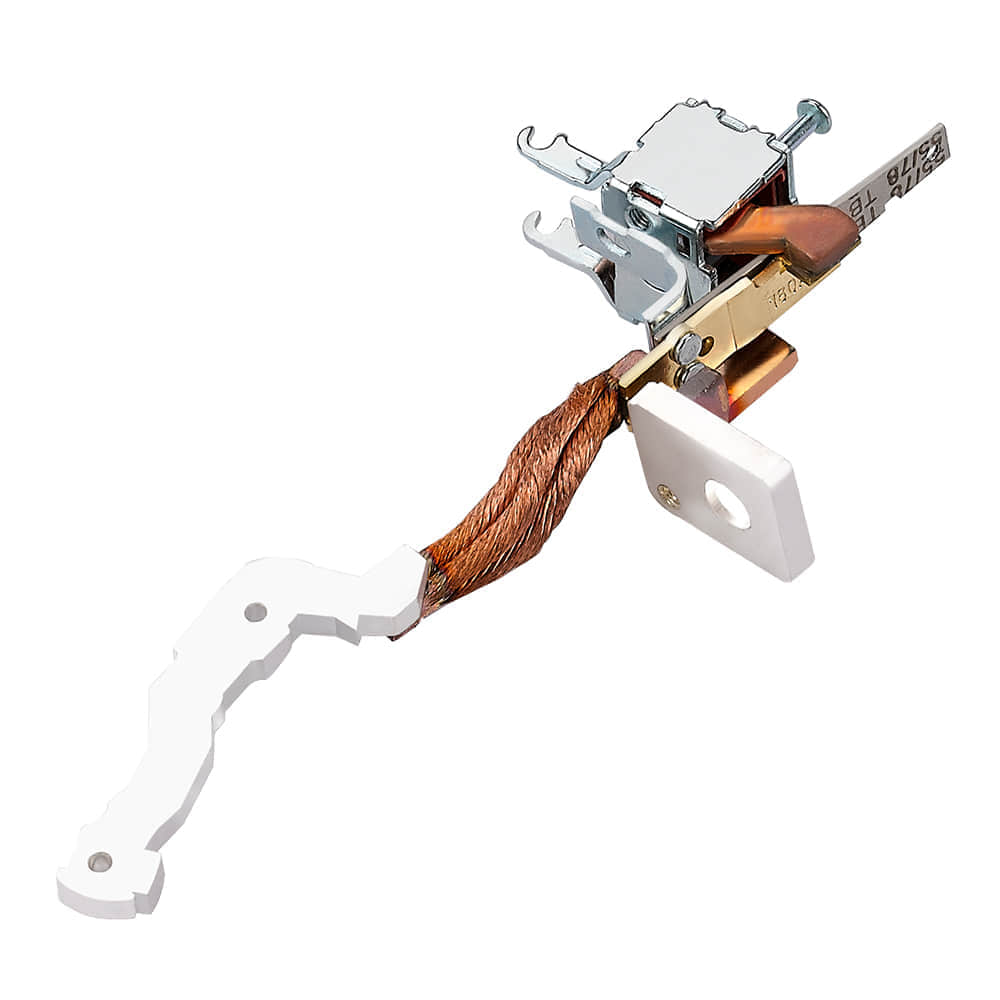

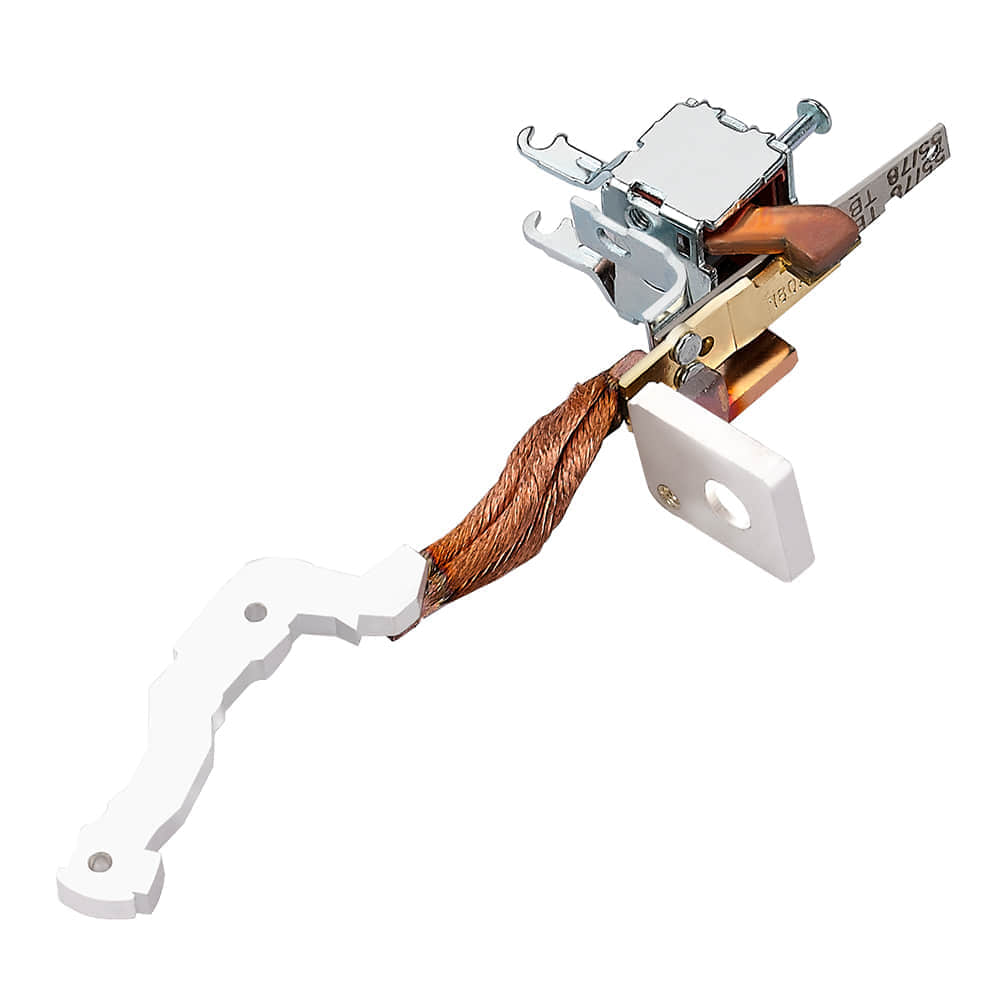

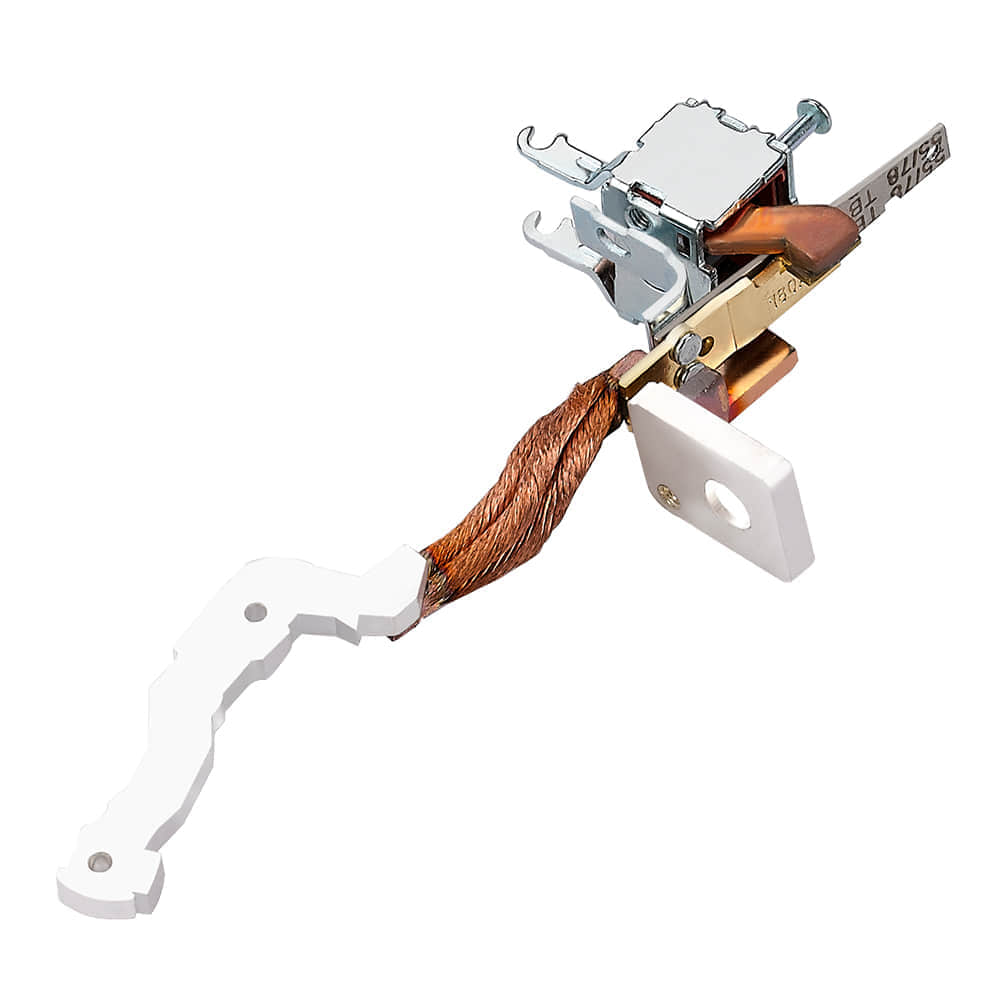

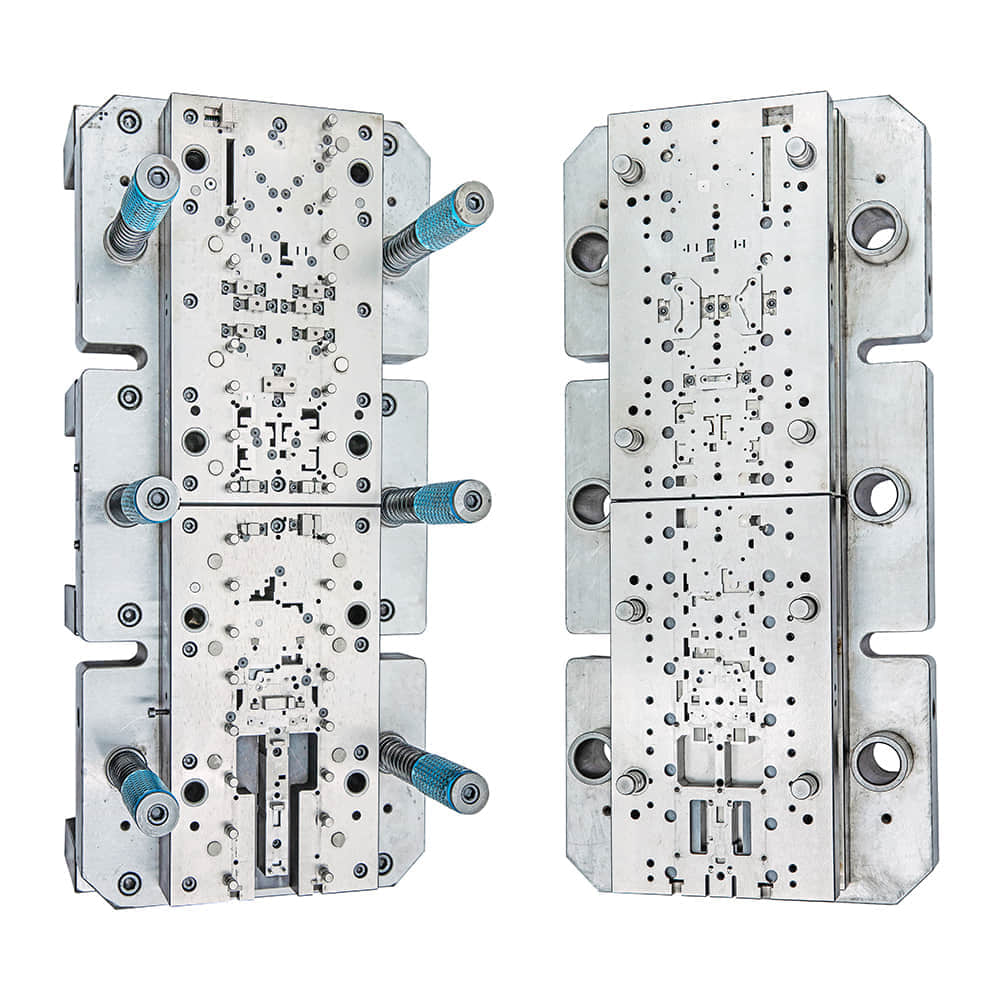

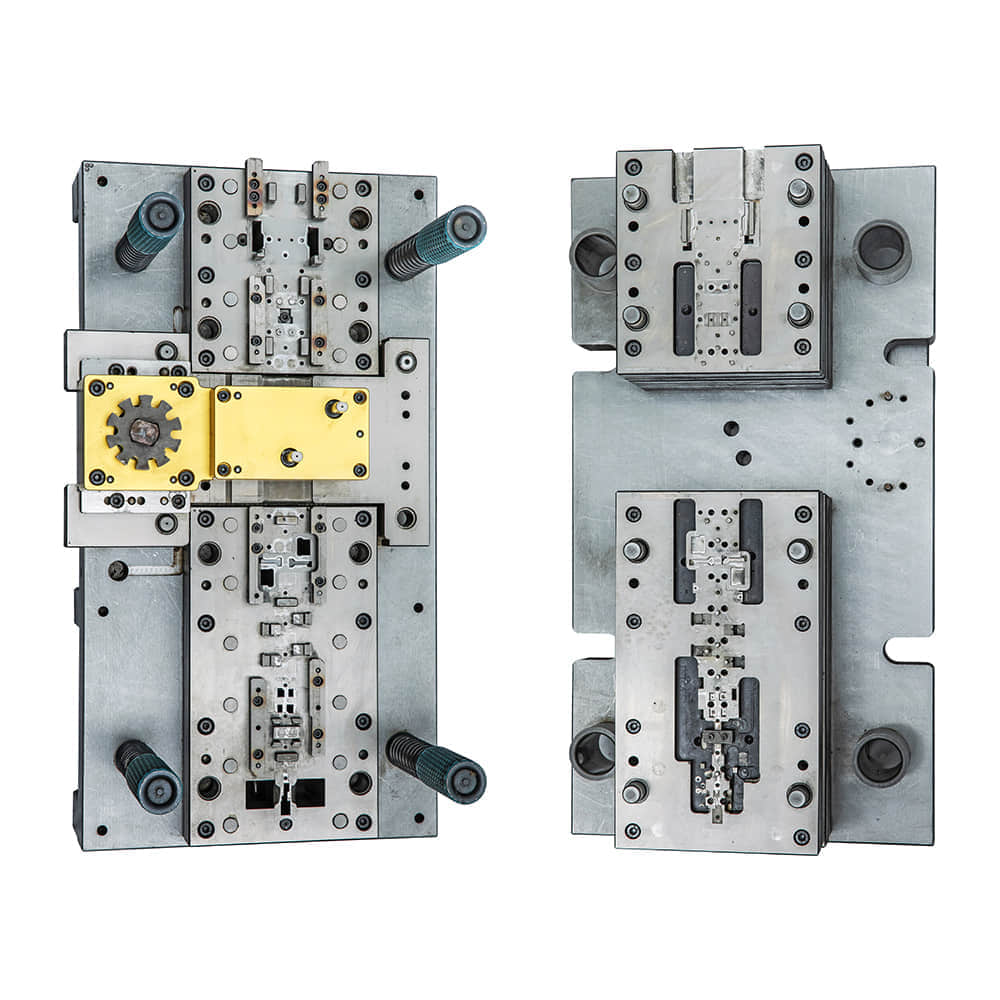

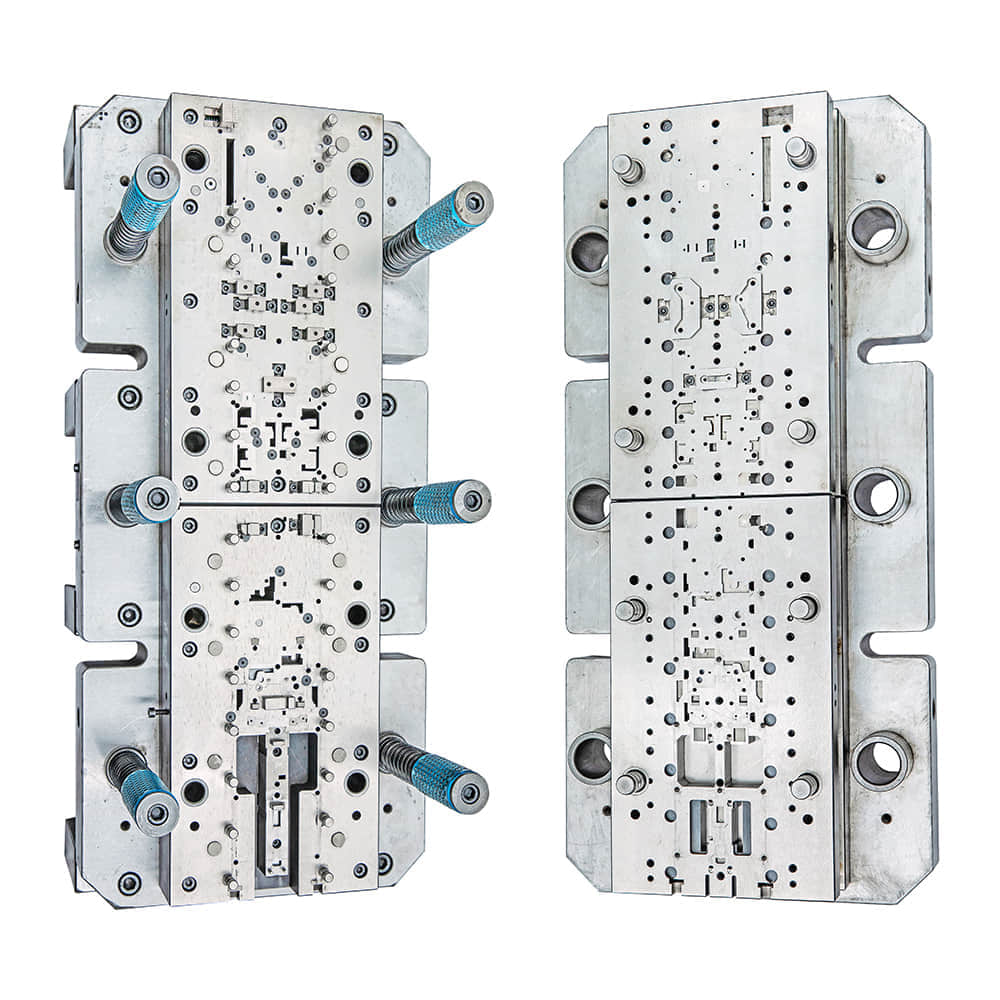

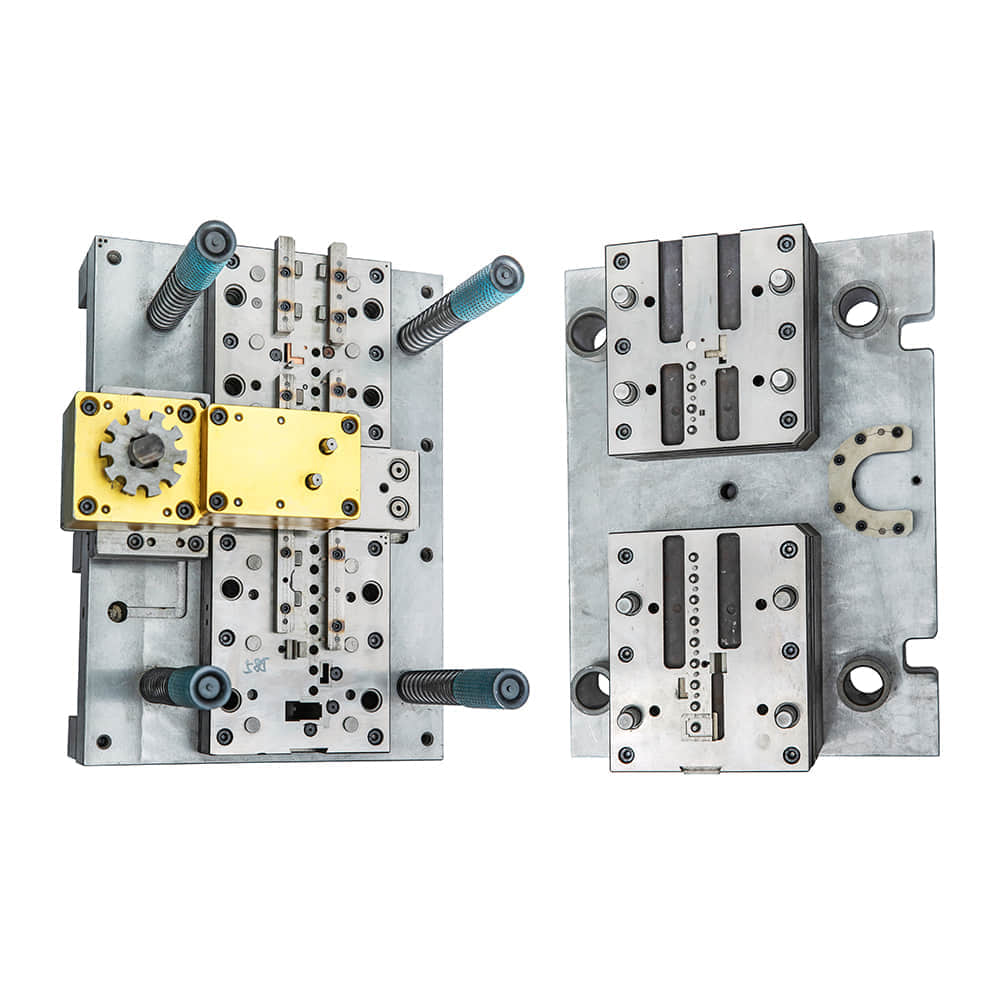

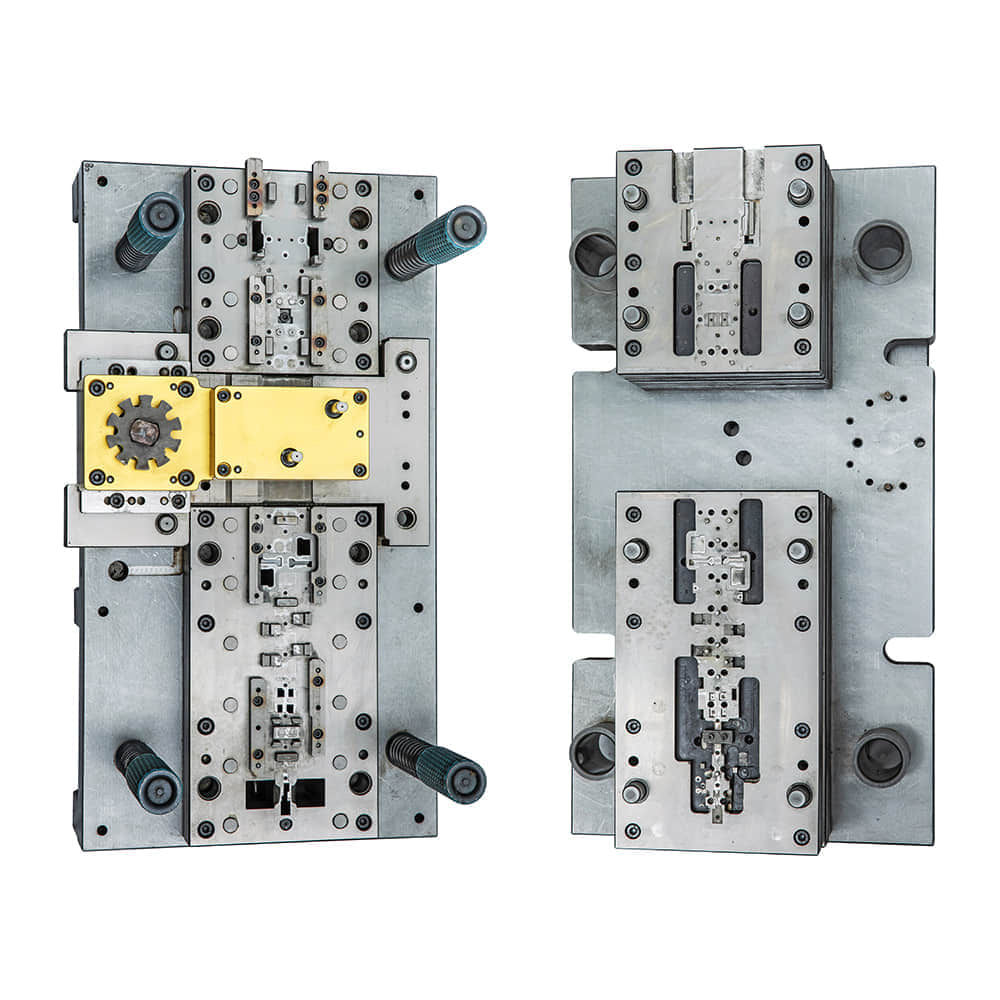

What Is a Molded Case Circuit Breaker (MCCB)? A Molded Case Circuit Breaker, often abbreviated as MCCB, is a type of electrical protection device used in power distribution systems. It is designed to provide protection against overcurrents, which can occur due to short circuits or overload conditions. These breakers are named “molded case” because their outer casing is typically made from a durable, molded insulating material. How Does an MCCB Work? MCCBs work based on a simple yet effective principle. They consist of a switch-like mechanism that opens and closes an electrical circuit. When the current flowing through the circuit exceeds a predetermined threshold, the MCCB’s internal mechanism trips, instantly disconnecting the circuit and interrupting the flow of electricity. This rapid response is crucial in preventing electrical fires, equipment damage, and electrical hazards. MCCBs come with adjustable trip settings, allowing them to be fine-tuned to match the specific needs of the electrical system they protect. The key trip settings include: Overload Protection:MCCBs monitor the continuous current flow in the circuit. If the current exceeds the rated capacity for an extended period (an overload), the breaker trips to prevent overheating and damage to wires and equipment. Short Circuit Protection:In the event of a short circuit, where an abnormally high current flows due to a fault, MCCBs react instantly to interrupt the current flow, preventing catastrophic damage. Ground Fault Protection:Some MCCBs incorporate ground fault protection to detect leakage currents to ground. This is crucial for safety in areas where electrical systems need to be particularly sensitive to any potential shocks, such as swimming pools or construction sites. Instantaneous Protection:This setting allows for the rapid interruption of the circuit without delay, offering additional protection against faults. Why Are MCCBs Essential? Safety:Safety is paramount in electrical systems. MCCBs play a pivotal role in preventing electrical fires, reducing the risk of electrocution, and protecting property and lives. Equipment Protection:Overcurrents can cause significant damage to electrical equipment. MCCBs help safeguard expensive machinery and appliances by preventing excessive currents. Reliability:Electrical systems need to be dependable. MCCBs contribute to system reliability by ensuring that faults are quickly addressed, minimizing downtime. Customization:The ability to adjust trip settings makes MCCBs versatile, as they can be tailored to the specific needs of various applications, from residential to industrial. Cost Savings:While they are an investment, MCCBs can save money in the long run by reducing the costs associated with equipment replacement, repairs, and downtime. In conclusion, Molded Case Circuit Breakers are the unsung heroes of our electrical systems. They silently guard against the invisible dangers of overcurrents, ensuring our homes, businesses, and industries run smoothly and safely. As we continue to rely on electricity to power our lives, let us not forget the essential role played by MCCBs in keeping the lights on and the world running.