In the realm of electrical systems and power management, frame circuit breakers are indispensable components that ensure the safety and efficiency of electrical networks. China has emerged as a global leader in the production of these crucial devices, with several top-tier OEM (Original Equipment Manufacturer) companies at the forefront of innovation and quality. In this article, we will delve into the world of China’s frame circuit breaker OEM manufacturing industry, exploring the reasons behind its success and the key players driving this growth.

The Rise of China’s Frame Circuit Breaker Industry

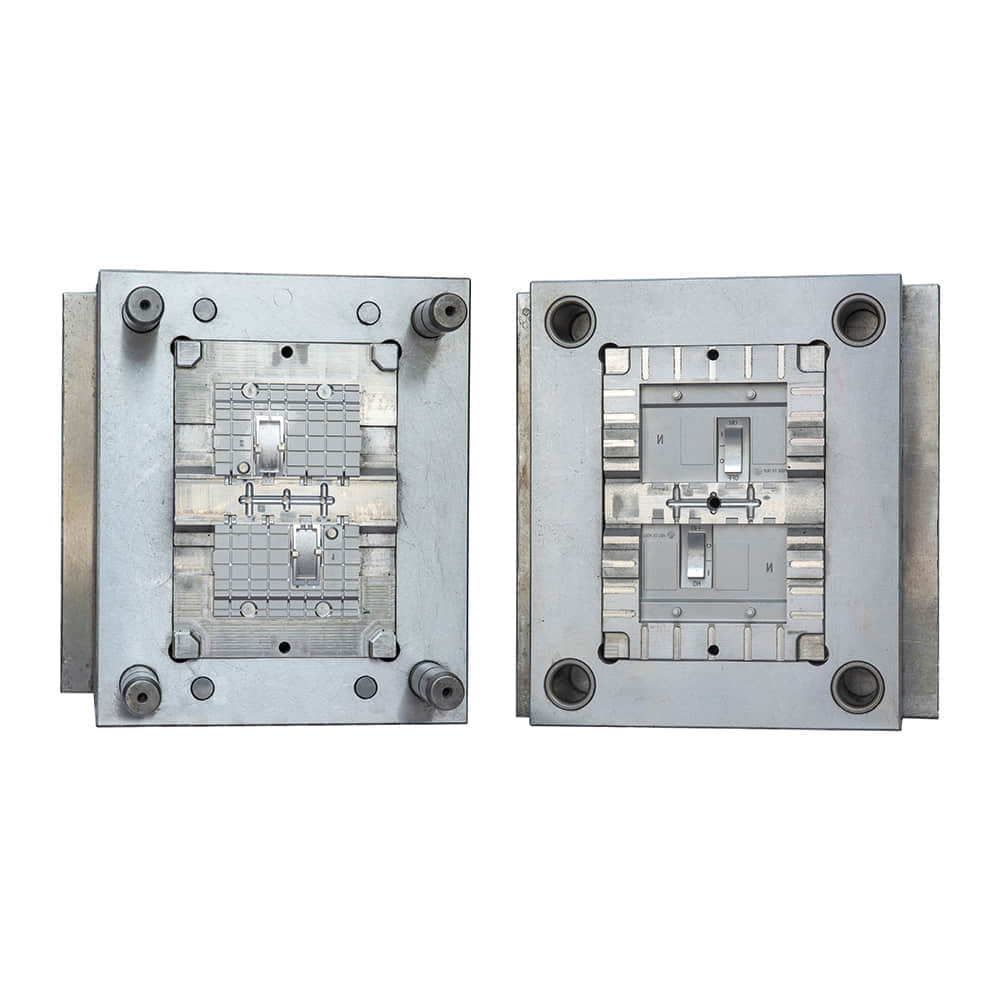

China’s journey to becoming a major player in the frame circuit breaker industry began with a strong focus on infrastructure development and manufacturing capabilities. As the country rapidly urbanized and its industries expanded, the demand for reliable and efficient electrical systems grew exponentially. Recognizing this opportunity, Chinese manufacturers started investing heavily in research and development, harnessing advanced technologies to create cutting-edge frame circuit breakers. Key Strengths of China’s OEM Manufacturers 1. Technological Advancements:Chinese OEM manufacturers have consistently pushed the boundaries of technology. They leverage state-of-the-art equipment and automation to enhance the precision and reliability of frame circuit breakers. This commitment to innovation has enabled them to meet international standards and gain recognition in global markets. 2. Cost-Effective Production:China’s OEMs benefit from economies of scale, allowing them to produce high-quality frame circuit breakers at competitive prices. This cost-effectiveness has made their products attractive to businesses and industries worldwide, driving the industry’s growth. 3. Stringent Quality Control:To build trust in their products, Chinese OEMs prioritize rigorous quality control measures. Advanced testing facilities and stringent quality checks ensure that frame circuit breakers meet or exceed safety and performance standards. Leading China-Based Frame Circuit Breaker OEM Manufacturers 1. Chint Group Corporation:As one of China’s largest electrical equipment manufacturers, Chint has a robust presence in the frame circuit breaker industry. Their products are renowned for their reliability, safety features, and affordability. Chint’s dedication to innovation has helped them secure a strong global market position. 2. Delixi Electric Group Co., Ltd:Delixi is another prominent player in the Chinese frame circuit breaker manufacturing sector. With a focus on sustainable practices and technological advancement, Delixi has gained recognition for producing eco-friendly and energy-efficient circuit breakers. 3. People Electrical Appliance Group Co., Ltd:People Electrical Appliance Group has carved a niche for itself with a wide range of electrical products, including frame circuit breakers. Their commitment to quality, backed by extensive research and development, has made them a trusted name in the industry. Global Reach and Impact China’s frame circuit breaker OEM manufacturers have not limited their reach to domestic markets. They have expanded their footprint worldwide, exporting their products to over 100 countries. This global presence has not only boosted the Chinese economy but has also contributed to the development of power infrastructure in various nations. The Future of China’s Frame Circuit Breaker OEM Industry As global demand for electricity continues to grow, the importance of reliable and efficient electrical systems becomes paramount. China’s frame circuit breaker OEM manufacturers are well-positioned to meet this demand. With ongoing investments in research, technology, and quality control, they are poised to maintain their leadership in the industry for years to come. In conclusion, China’s rise as a powerhouse in the frame circuit breaker OEM manufacturing sector is a testament to its commitment to excellence, innovation, and quality. The industry’s top players, including Chint Group Corporation, Delixi Electric Group Co., Ltd, and People Electrical Appliance Group Co., Ltd, have set high standards and have successfully expanded their presence on the global stage. As the world continues to rely on electricity for its growth and development, China’s OEM manufacturers are set to play a pivotal role in shaping the future of electrical systems and power management.