In the realm of metalworking and manufacturing, precision is paramount. One of the key technologies that ensure the accuracy and efficiency of metal part production is metal stamping dies. These crucial tools have seen a revolution in recent years, thanks to Original Design Manufacturer (ODM) companies specializing in their creation. In this article, we will delve into the world of Metal Stamping Die ODM Manufacturers and explore the significant role they play in modern industry.

The Role of Metal Stamping Dies

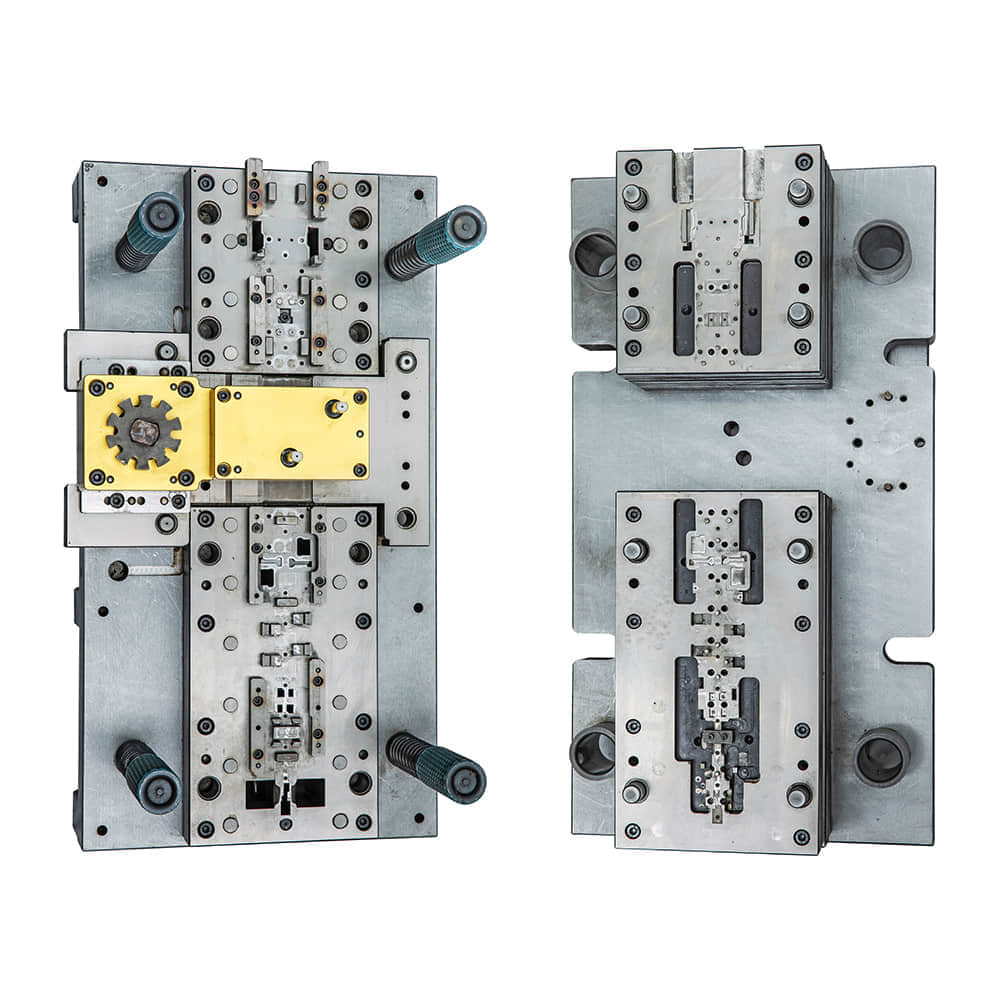

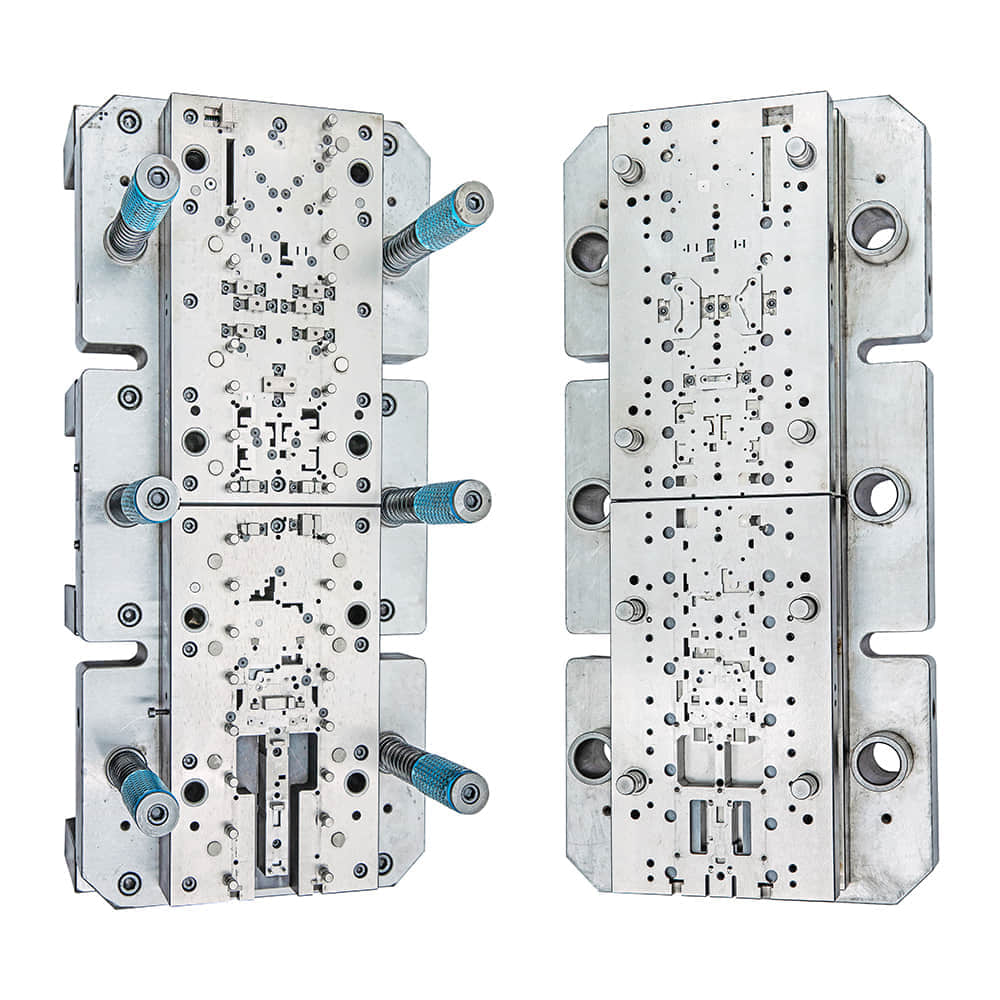

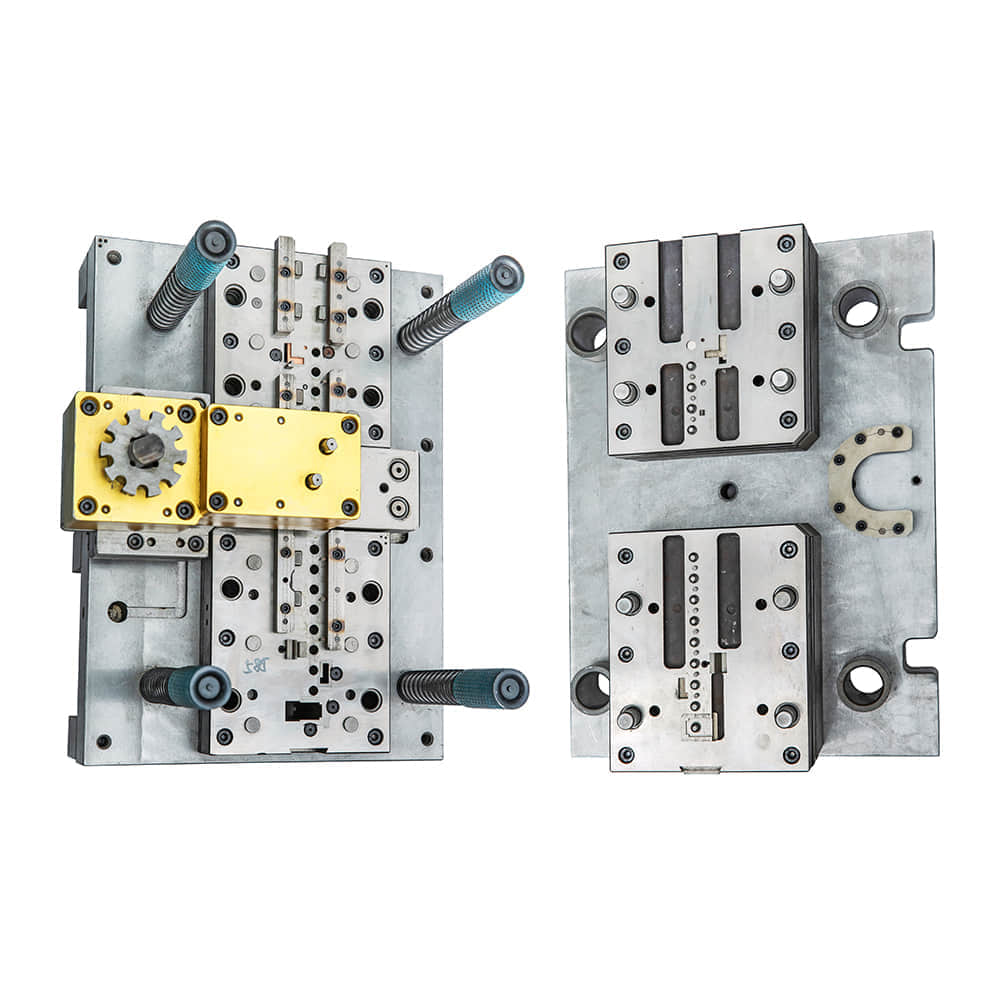

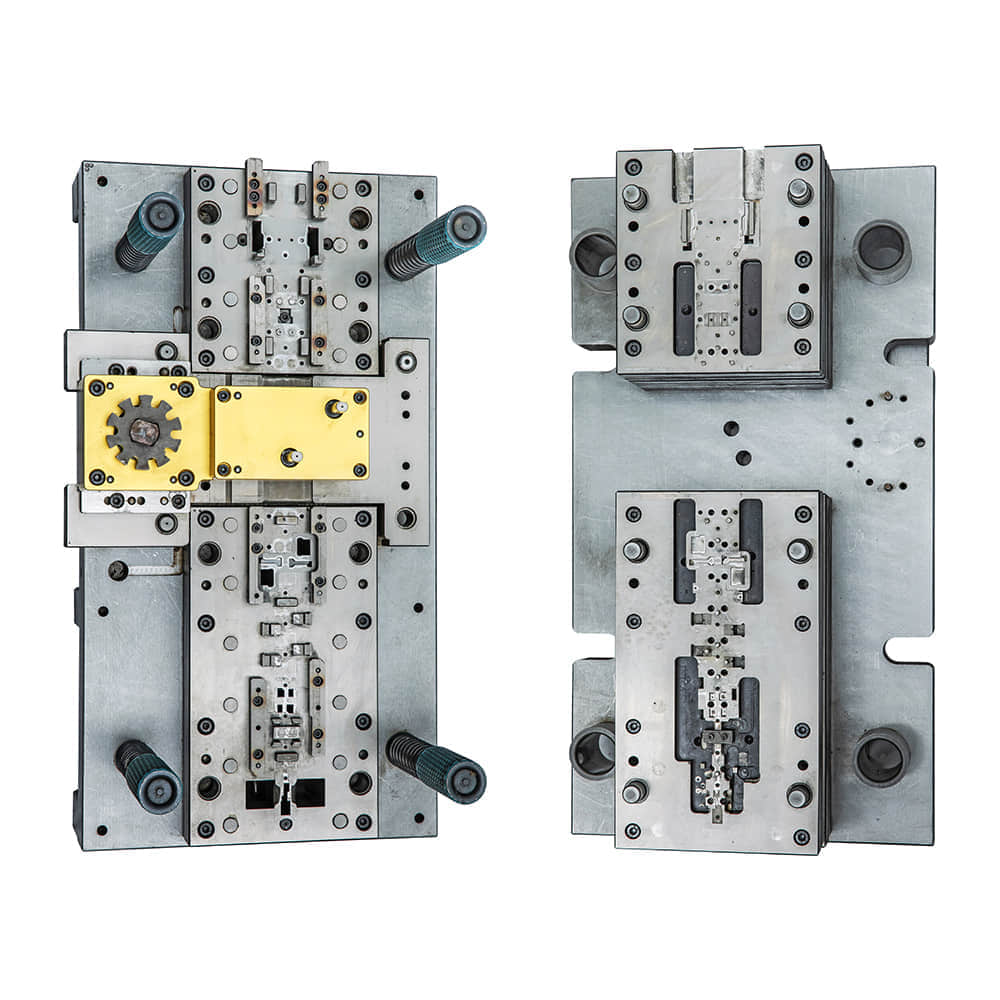

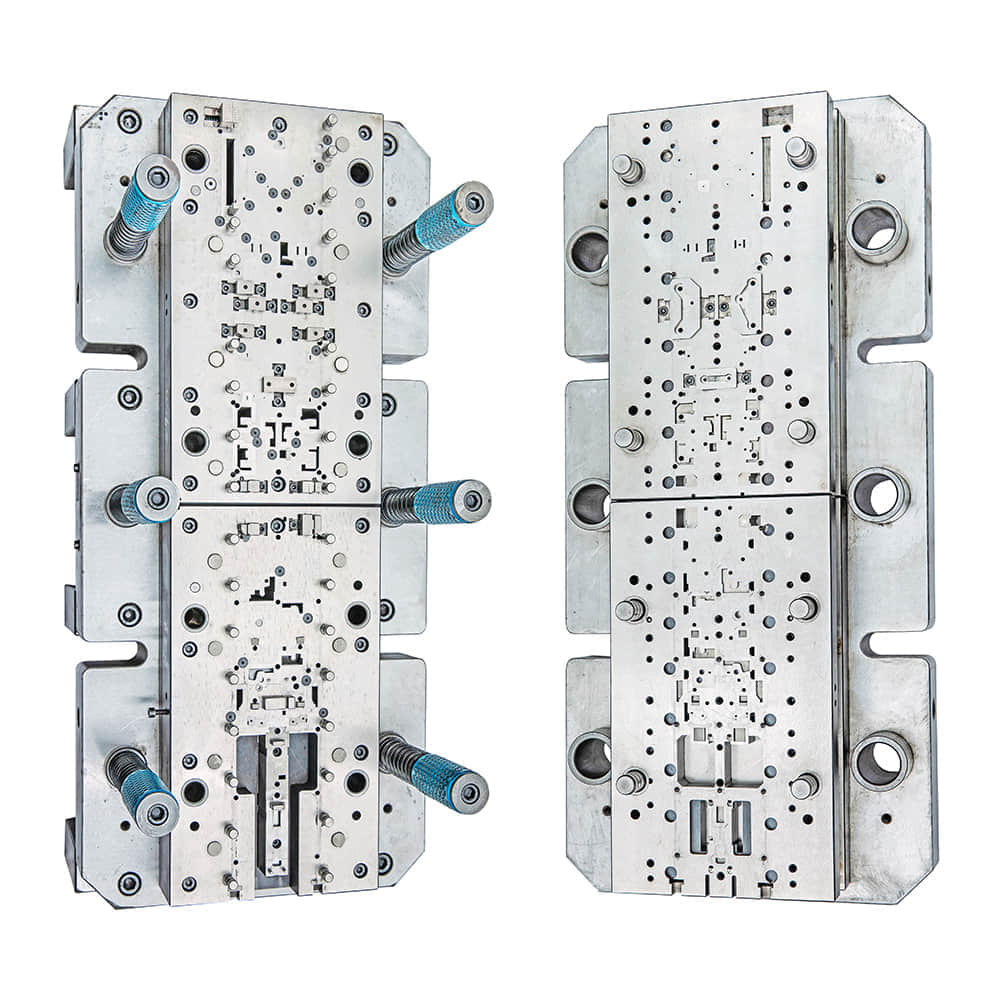

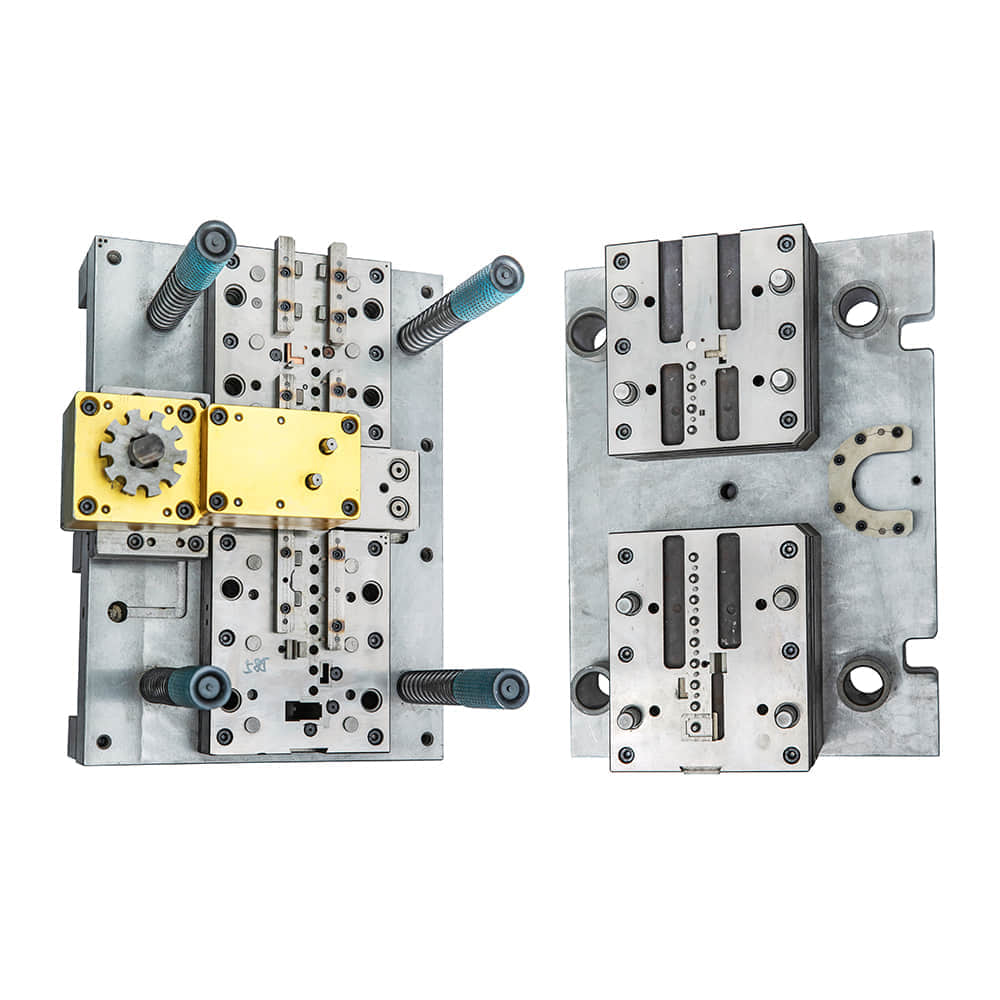

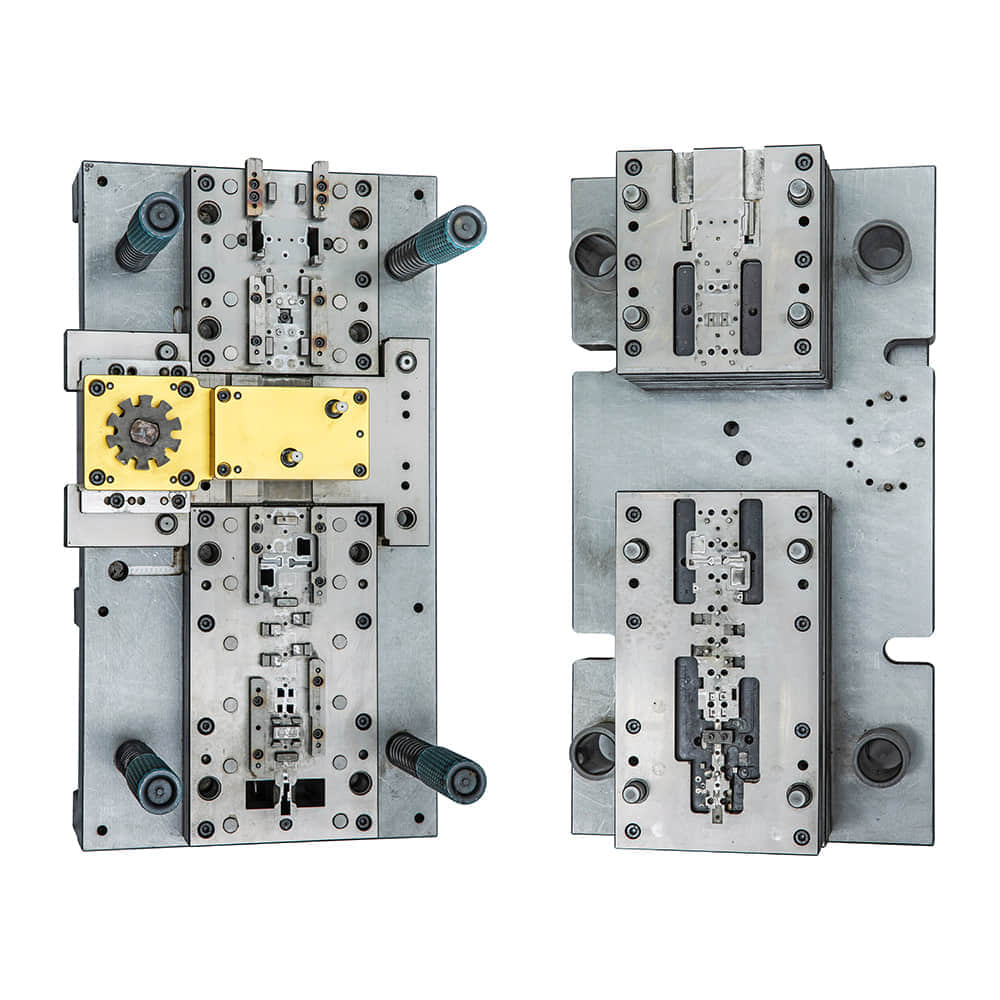

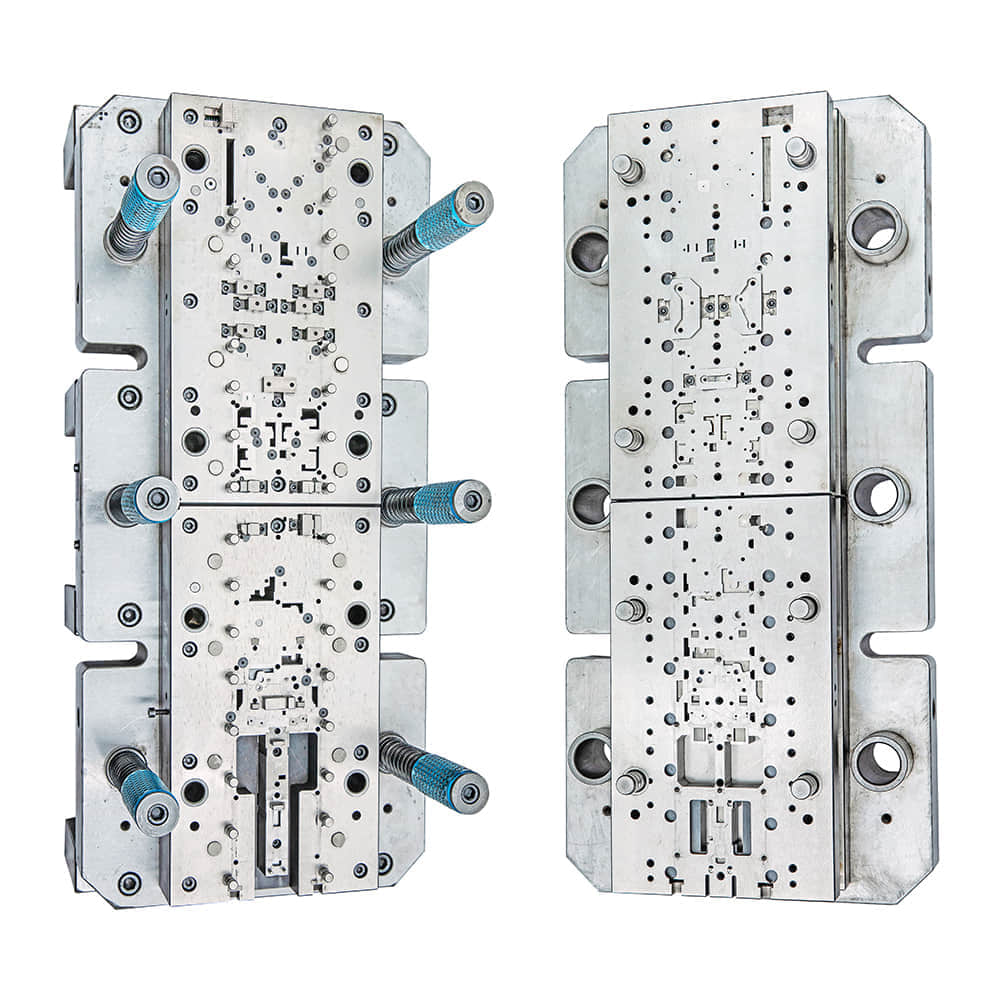

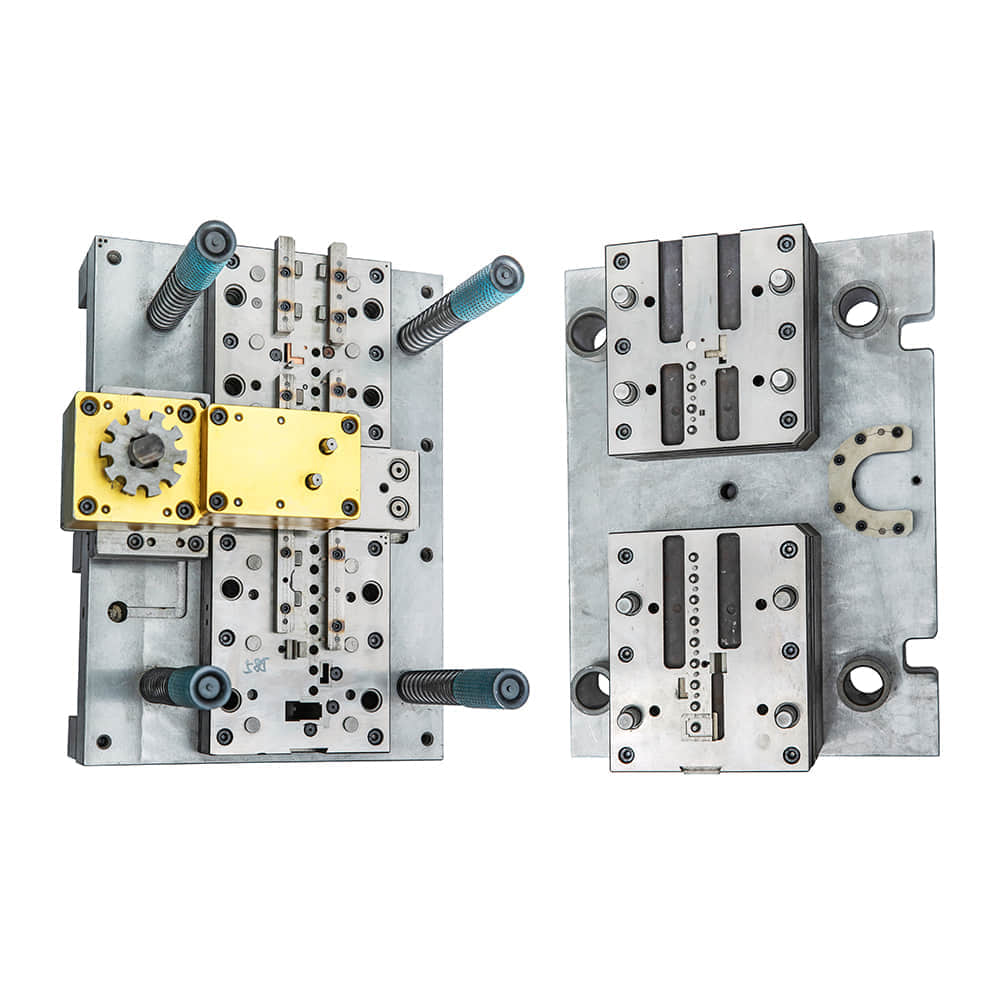

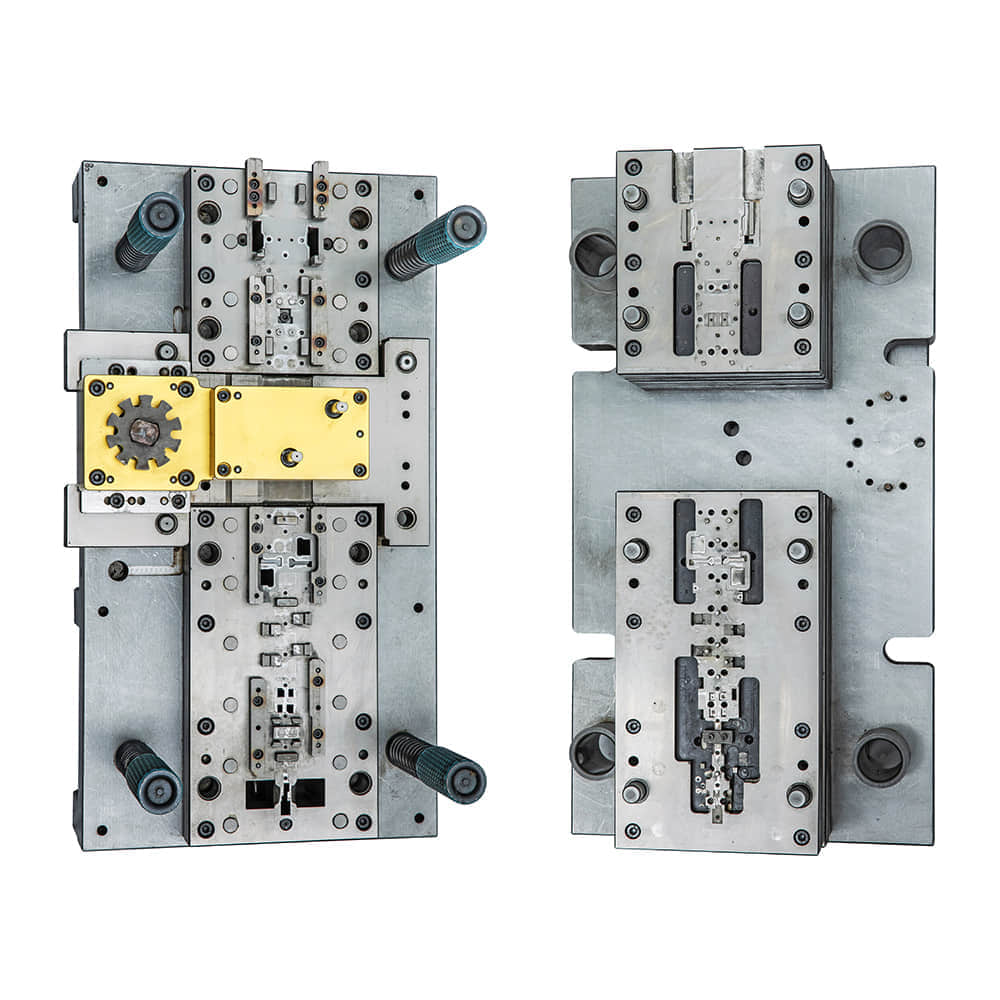

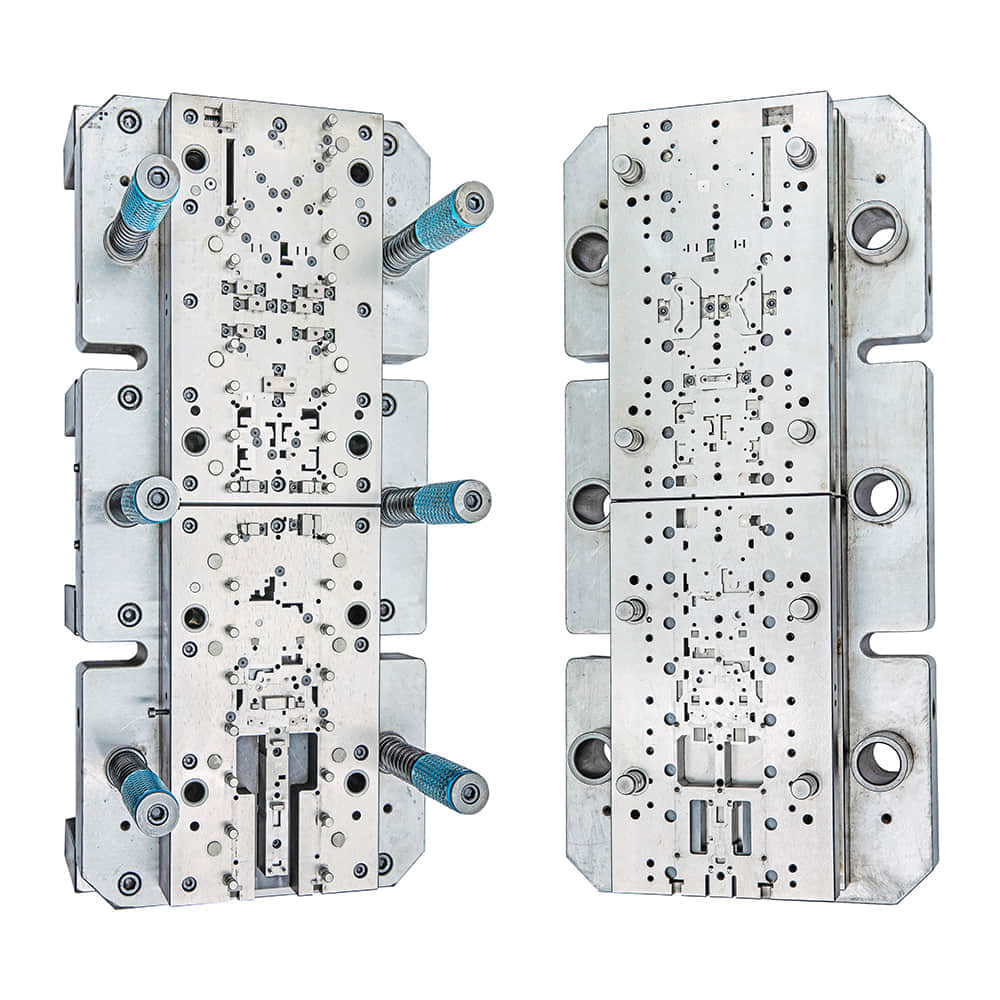

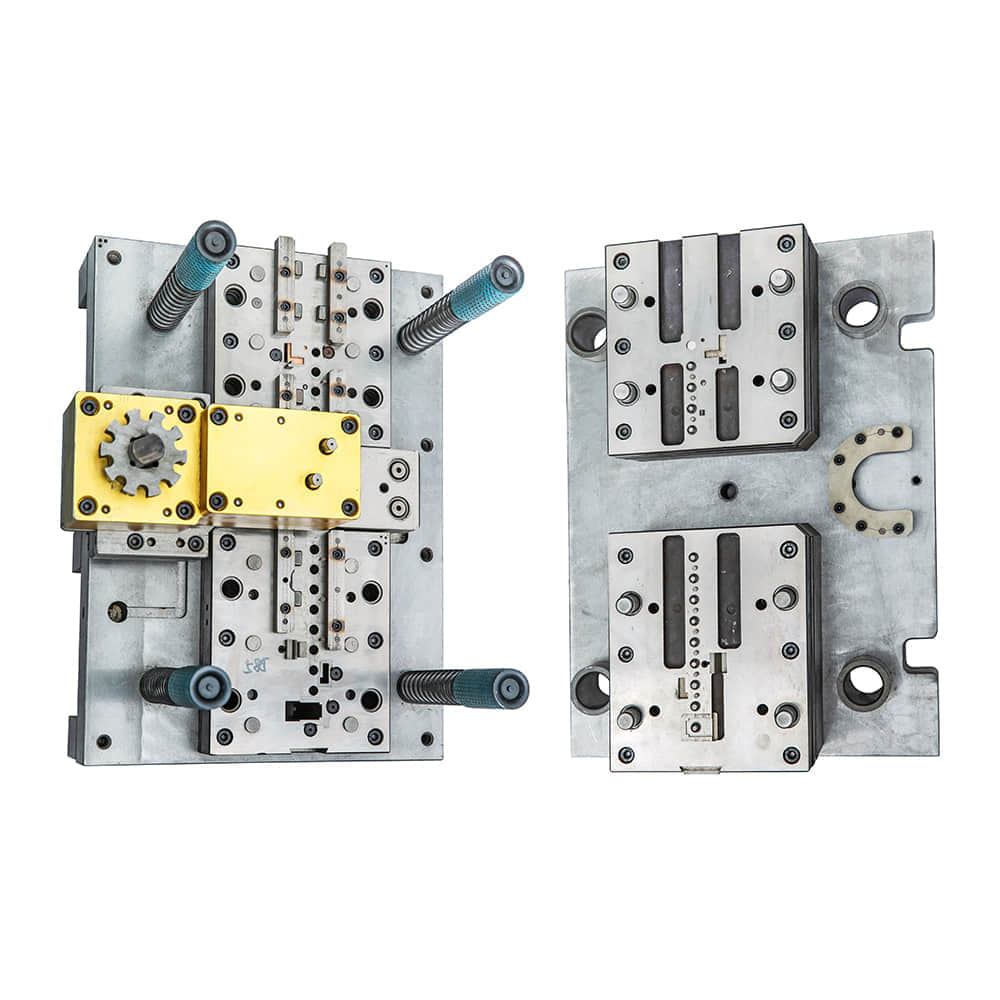

Metal stamping dies are instrumental in shaping and forming metal sheets or parts into the desired configuration. They are used across a wide spectrum of industries, from automotive and aerospace to electronics and consumer goods. The accuracy and quality of these dies directly impact the final product’s precision, consistency, and overall cost-effectiveness. The Evolution of Metal Stamping Die Manufacturing Traditionally, metal stamping dies were fabricated in-house by manufacturers. However, the demands of modern production have led to a shift in this approach. Today, many companies are turning to specialized ODM manufacturers for their metal stamping die needs. Advantages of Metal Stamping Die ODM Manufacturers Expertise and Specialization:ODM manufacturers are dedicated experts in their field. They invest heavily in research, development, and technology to stay at the forefront of metal stamping die innovation. This specialization ensures that their products are of the highest quality and precision. Customization:ODM manufacturers offer a high degree of customization. They work closely with clients to design and create stamping dies that meet their specific needs. This flexibility is crucial in industries where product designs evolve rapidly. Cost-Effective:Outsourcing metal stamping die production to ODM manufacturers can often be more cost-effective than maintaining an in-house production facility. ODMs benefit from economies of scale, allowing them to produce high-quality dies at competitive prices. Time Efficiency:ODM manufacturers have streamlined production processes and can deliver dies quickly. This is especially important in industries where time-to-market is critical. Quality Assurance:Reputable ODM manufacturers implement rigorous quality control measures throughout the manufacturing process. This ensures that the final product meets or exceeds industry standards. Innovations in Metal Stamping Die Technology ODM manufacturers are at the forefront of technological innovations in metal stamping die production. Some notable advancements include: Digital Design:Utilizing sophisticated computer-aided design (CAD) software, ODMs can create highly complex and precise die designs. This digital approach allows for faster prototyping and refinement. Material Advancements:ODMs are continually exploring new materials, coatings, and treatments to enhance the durability and performance of stamping dies. This results in longer tool life and reduced maintenance costs. Automation:The integration of automation and robotics in die manufacturing streamlines the production process, reduces human error, and enhances efficiency. Data Analytics:ODMs are increasingly leveraging data analytics to monitor and optimize die performance. Predictive maintenance based on data analysis minimizes downtime and improves overall productivity. Conclusion In the world of metal stamping die manufacturing, ODM companies are driving innovation and setting new standards for quality, precision, and efficiency. Their specialized expertise, commitment to customization, cost-effectiveness, and embrace of cutting-edge technology make them indispensable partners for industries reliant on metal stamping processes. As demand for precision-engineered metal parts continues to grow, Metal Stamping Die ODM Manufacturers are poised to play an even more significant role in shaping the future of manufacturing.