In the ever-evolving world of manufacturing, precision and innovation are two key factors that determine the success of a company. When it comes to metal stamping dies, one name stands out – China Metal Stamping Die Manufacturer. With a rich history, a commitment to quality, and a focus on cutting-edge technology, this company has become a cornerstone in the global manufacturing landscape.

China Metal Stamping Die Manufacturer, founded several decades ago, has consistently pushed the boundaries of what’s possible in metal stamping die production. Their journey from a small, local shop to a renowned global player is a testament to their dedication and excellence in the field.

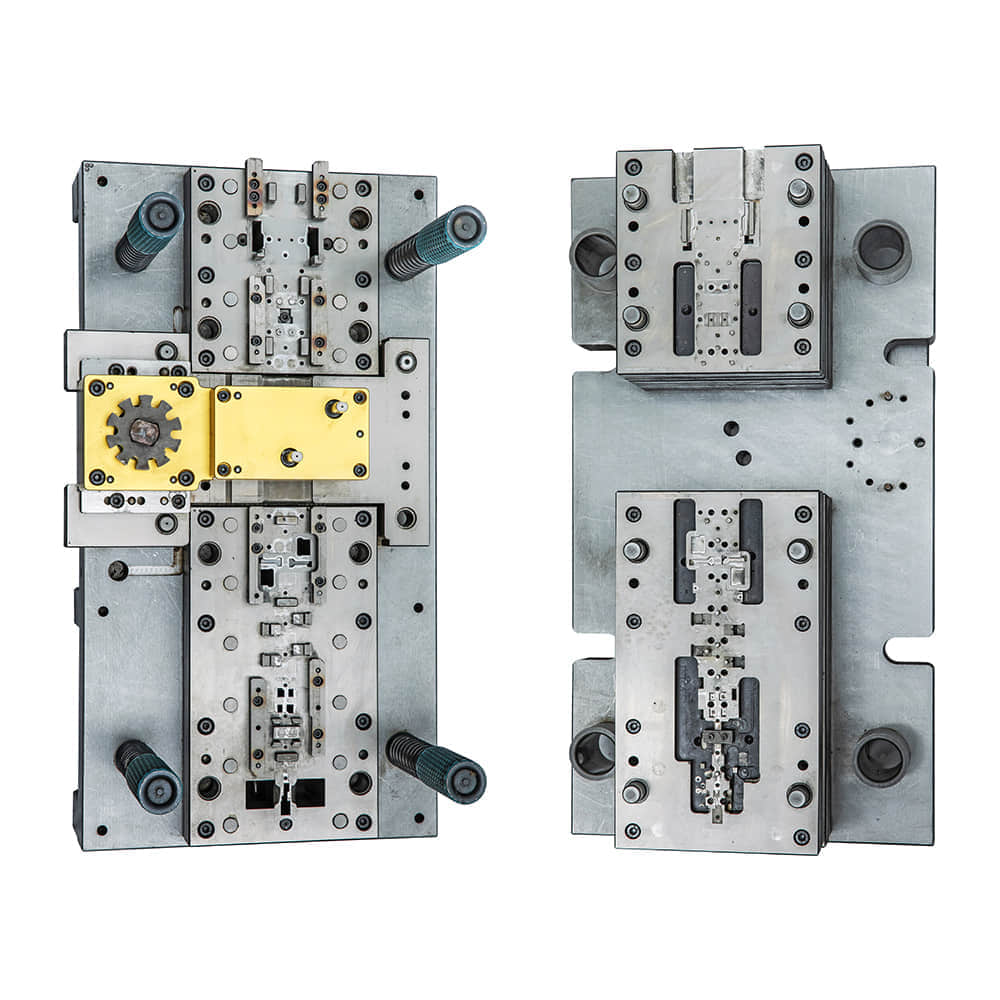

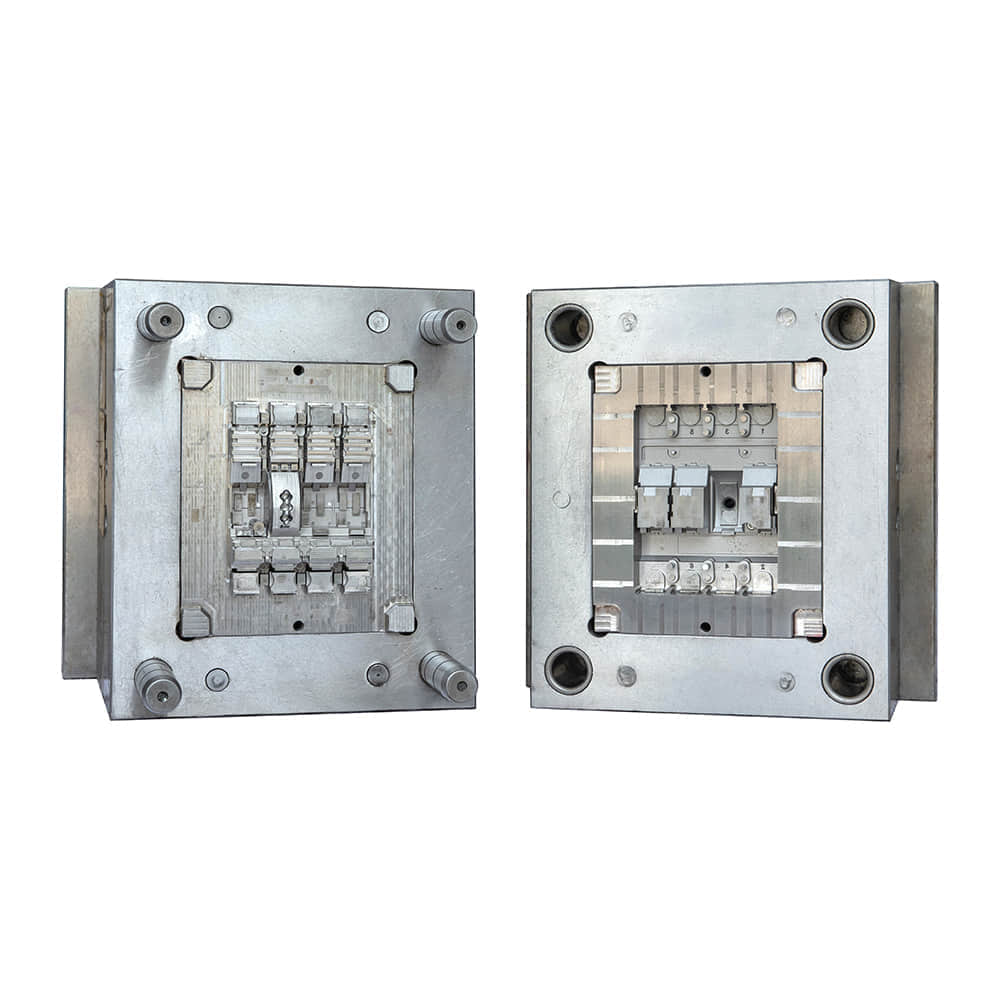

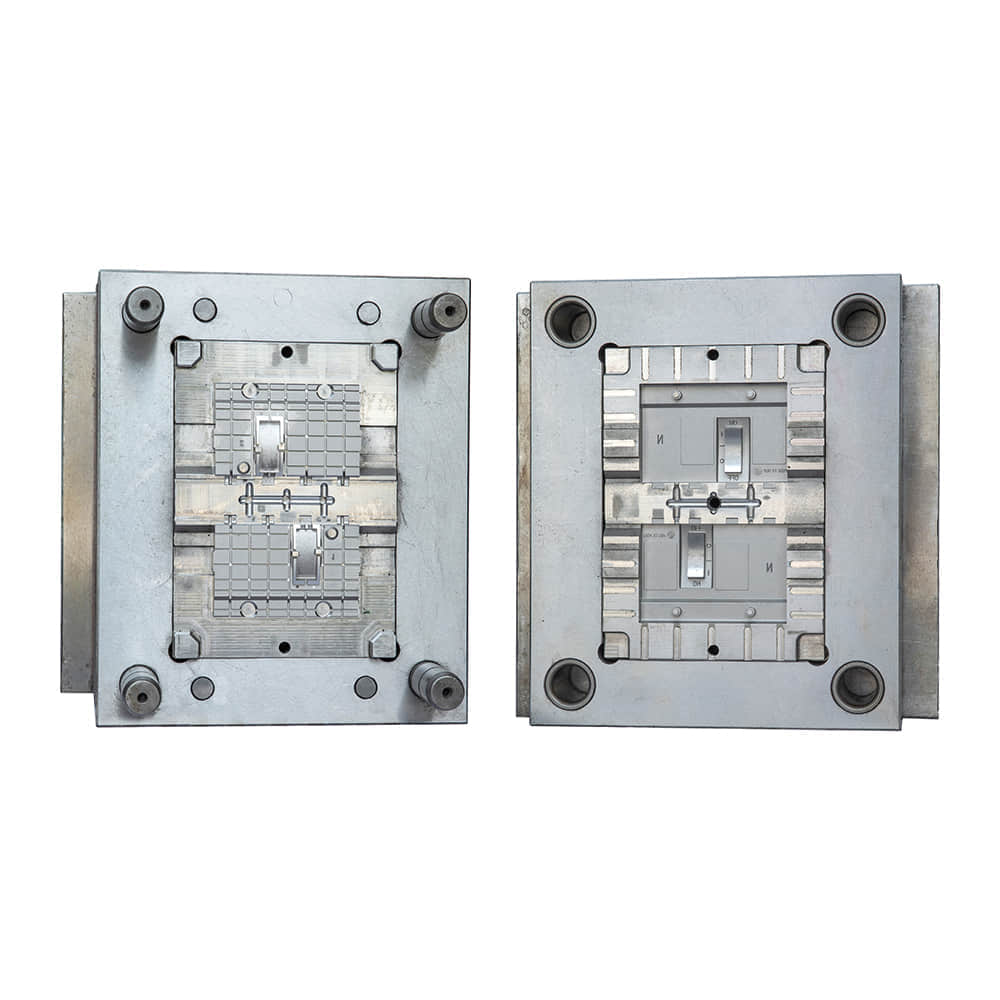

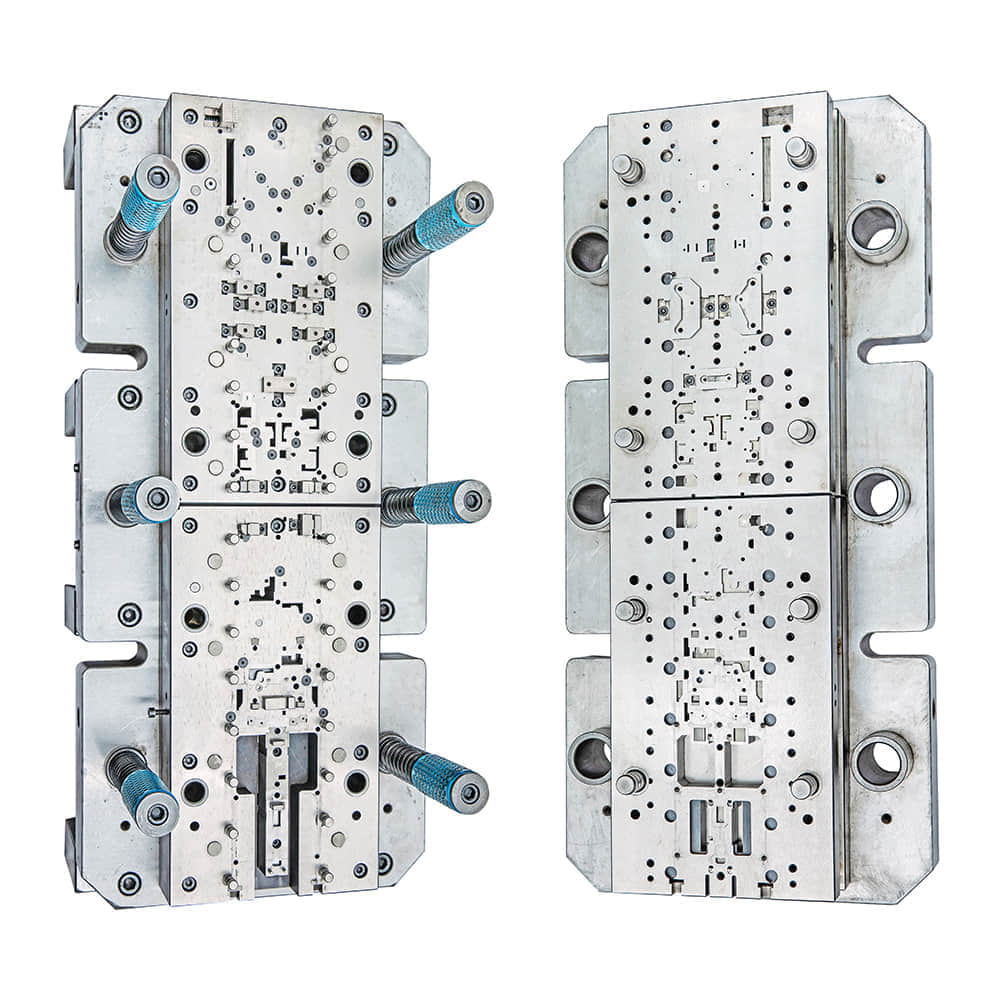

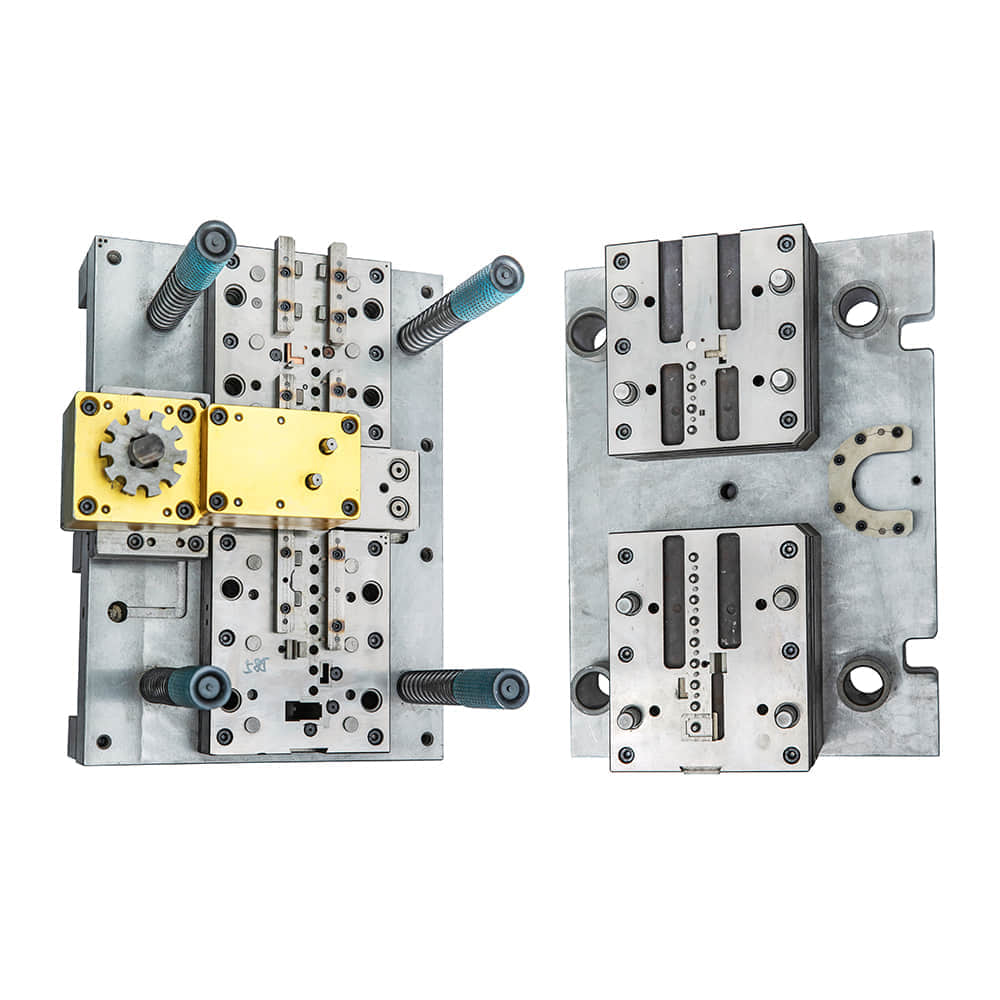

A Heritage of Excellence The company’s journey began with a small group of skilled craftsmen who were passionate about creating precision tools. Over the years, they honed their craft and expanded their expertise. Today, China Metal Stamping Die Manufacturer boasts a team of highly skilled engineers, designers, and technicians who collectively bring decades of experience to the table. Their commitment to excellence is deeply rooted in their heritage. Each stamping die produced carries with it the legacy of craftsmanship passed down through generations. This heritage ensures that every product leaving their facility meets the highest standards of quality and precision. Investment in Technology To stay at the forefront of the industry, China Metal Stamping Die Manufacturer has continually invested in cutting-edge technology. They understand that innovation is the driving force behind progress, and they leverage the latest advancements to develop innovative solutions for their clients. Computer-aided design (CAD) and computer-aided manufacturing (CAM) are integral to their process, allowing for the creation of complex and intricate stamping dies with unparalleled precision. This technology also enables them to optimize production processes, reducing lead times and costs while maintaining the highest quality standards. Global Reach China Metal Stamping Die Manufacturer’s reputation for excellence extends far beyond its home country. Their commitment to delivering exceptional products and services has earned them a global clientele. They collaborate with companies across various industries, from automotive to electronics, providing tailored solutions that meet the unique demands of each sector. Their international presence is bolstered by a network of strategic partnerships and distributors, ensuring that their stamping dies are readily available to manufacturers worldwide. This global reach has solidified their position as a trusted partner for businesses seeking top-tier metal stamping die solutions. Quality Assurance Quality assurance is at the core of China Metal Stamping Die Manufacturer’s operations. They adhere to stringent quality control processes at every stage of production, from design and engineering to manufacturing and inspection. This commitment to quality is further underscored by their certifications, including ISO 9001, which attests to their dedication to continuous improvement. Environmental Responsibility In an era of growing environmental consciousness, China Metal Stamping Die Manufacturer takes its responsibility seriously. They are committed to sustainable manufacturing practices, striving to minimize waste, reduce energy consumption, and lower their environmental footprint. Their dedication to environmental responsibility is reflected in their eco-friendly production processes and the materials they use. Conclusion China Metal Stamping Die Manufacturer’s journey from a small local shop to a global leader in metal stamping die manufacturing is a testament to their unwavering commitment to excellence, innovation, and quality. With a heritage of craftsmanship, a dedication to cutting-edge technology, and a global reach, they continue to shape the future of the manufacturing industry. Whether you’re in need of precision stamping dies for automotive components or intricate electronics, China Metal Stamping Die Manufacturer stands ready to deliver solutions that exceed your expectations. Their legacy of excellence is an assurance of quality that you can trust in every project.