In today’s rapidly advancing technological landscape, the demand for reliable and efficient electrical systems has never been higher. At the heart of these systems lies the electronic molded case circuit breaker, a crucial component responsible for safeguarding electrical circuits and preventing overloads. As we delve into the world of electronic molded case circuit breakers, we discover the innovations that manufacturers are bringing to the table to meet the ever-evolving needs of industries and consumers alike.

1. Introduction to Electronic Molded Case Circuit Breakers

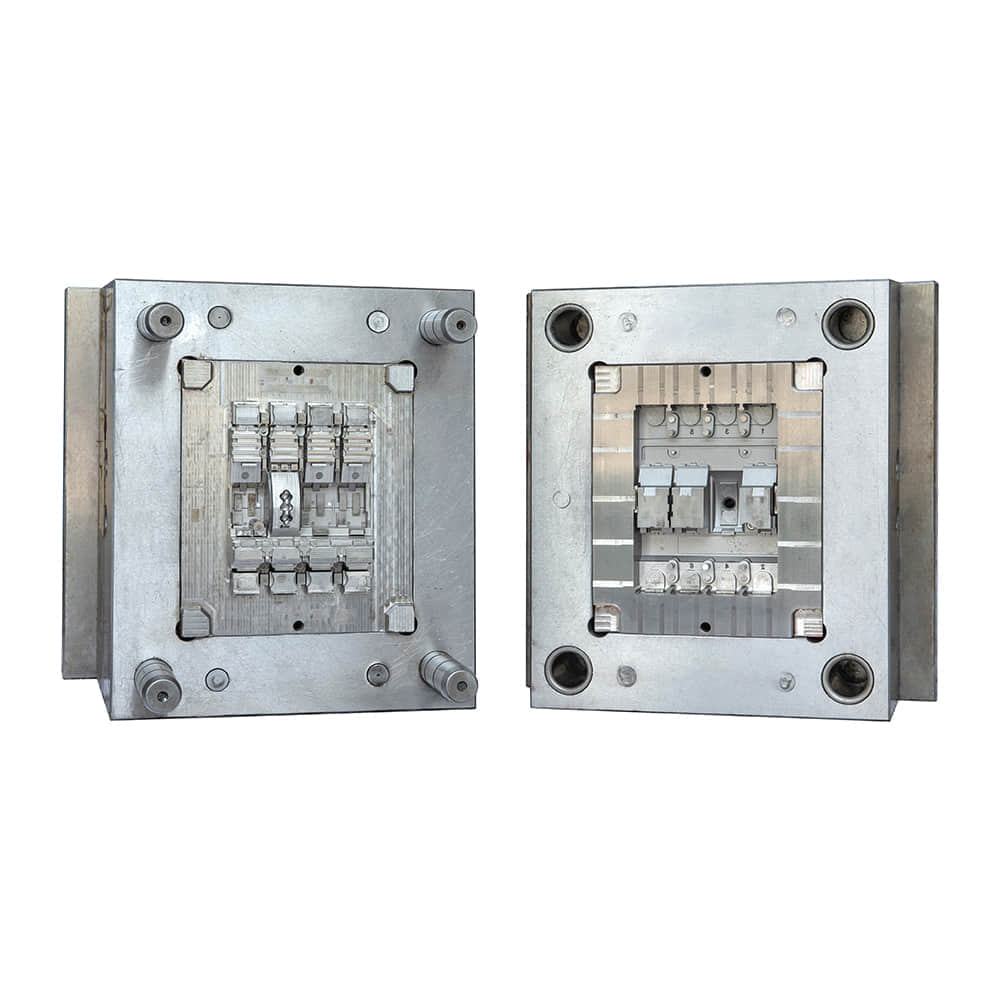

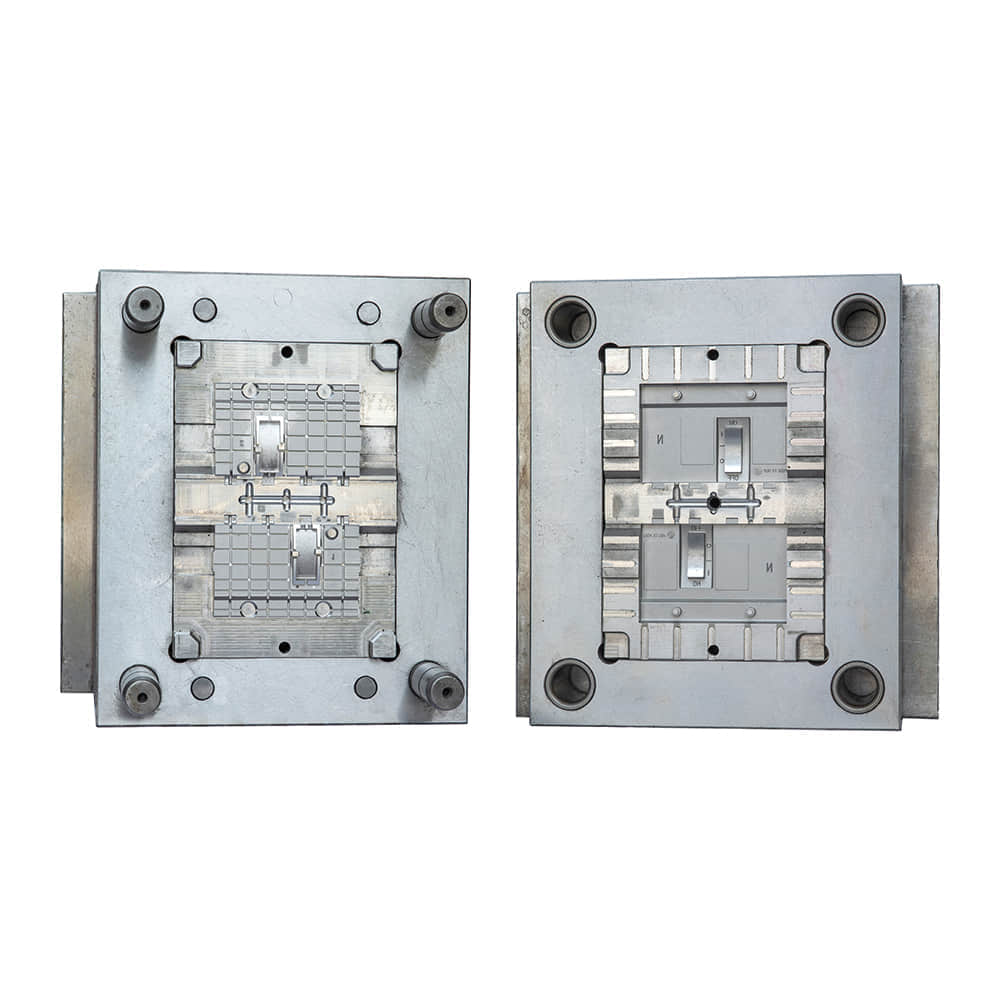

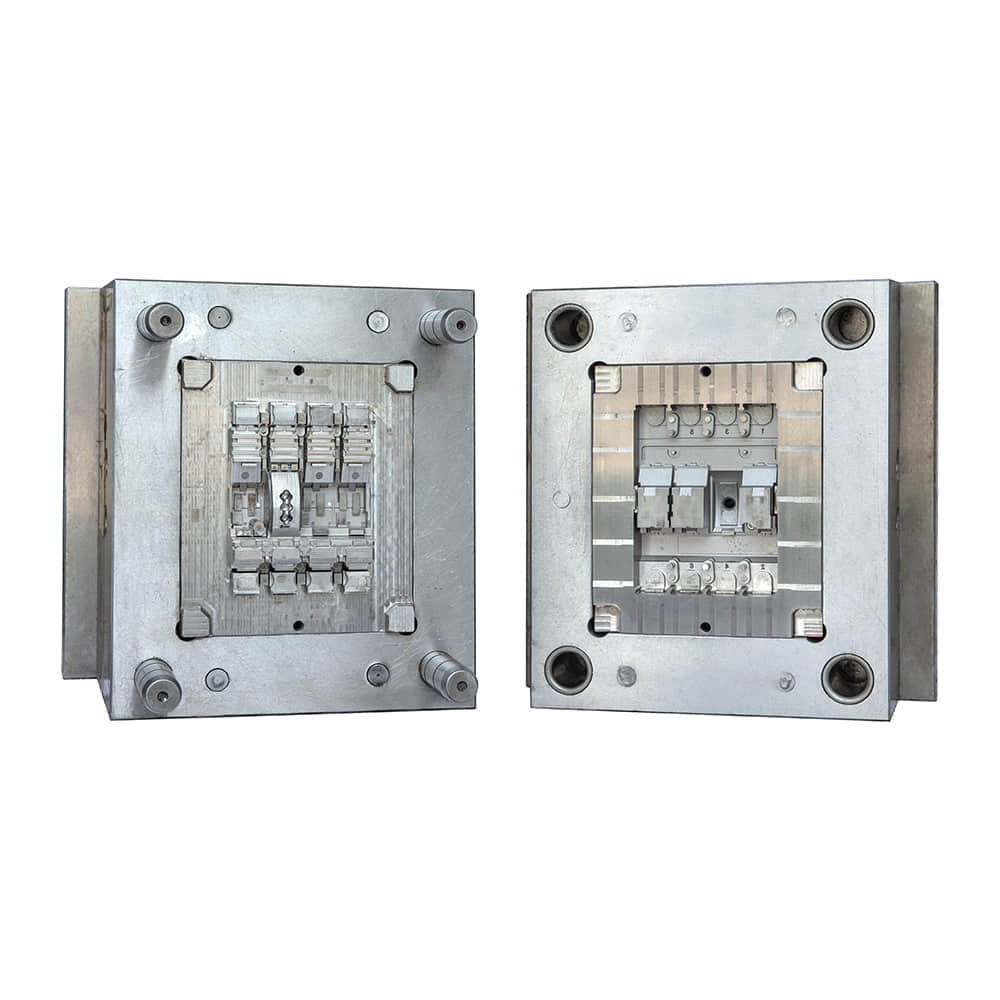

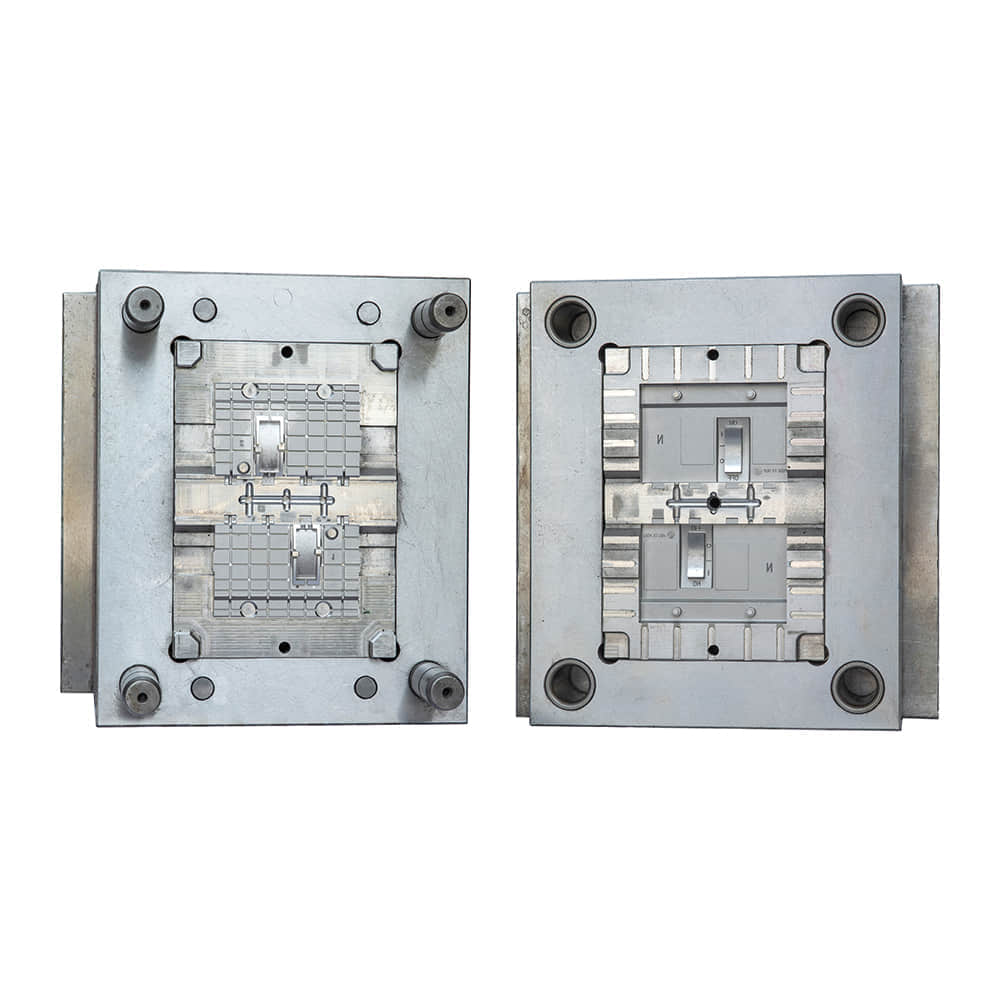

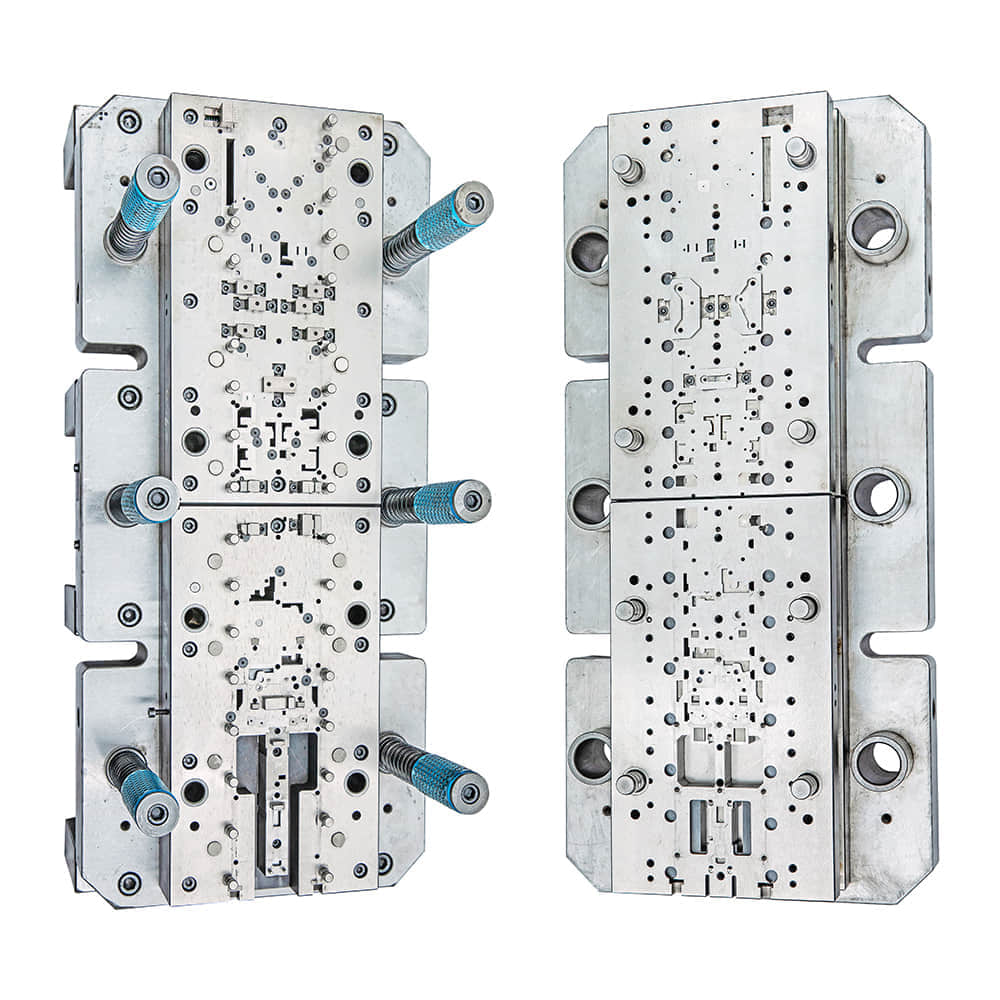

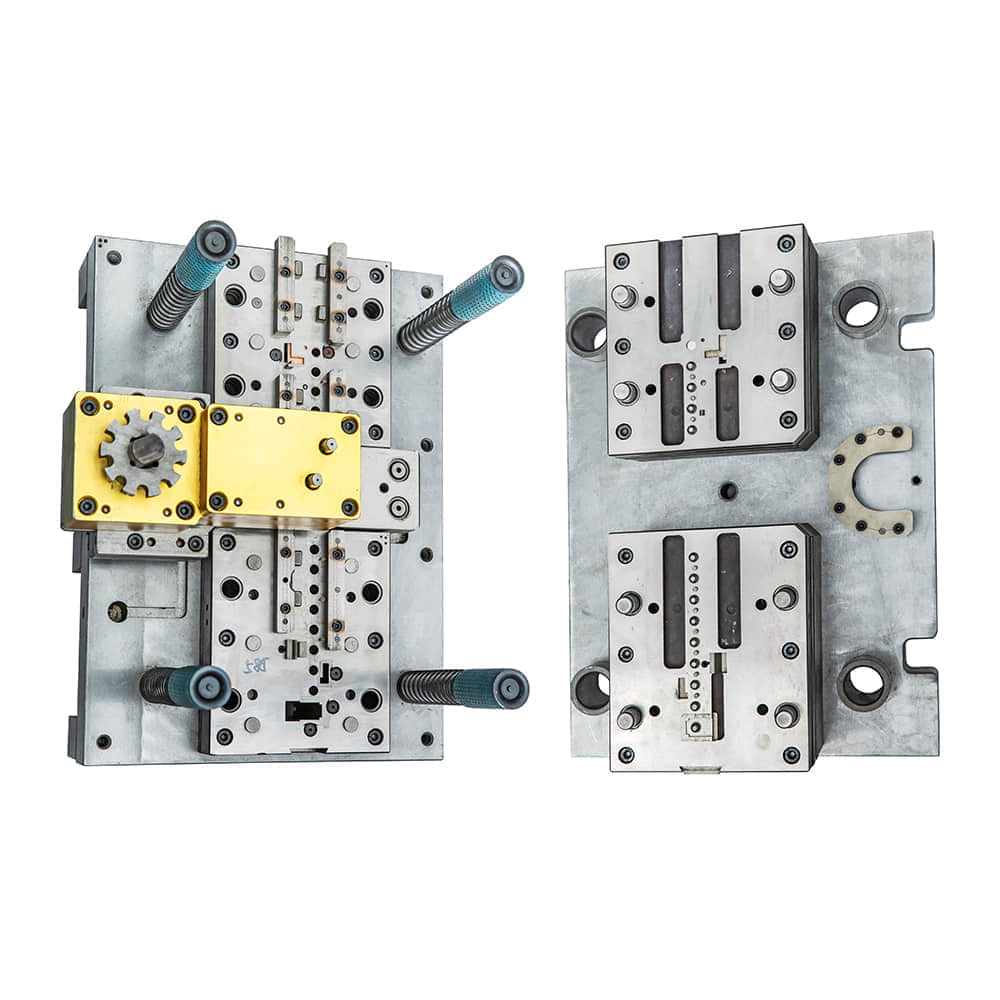

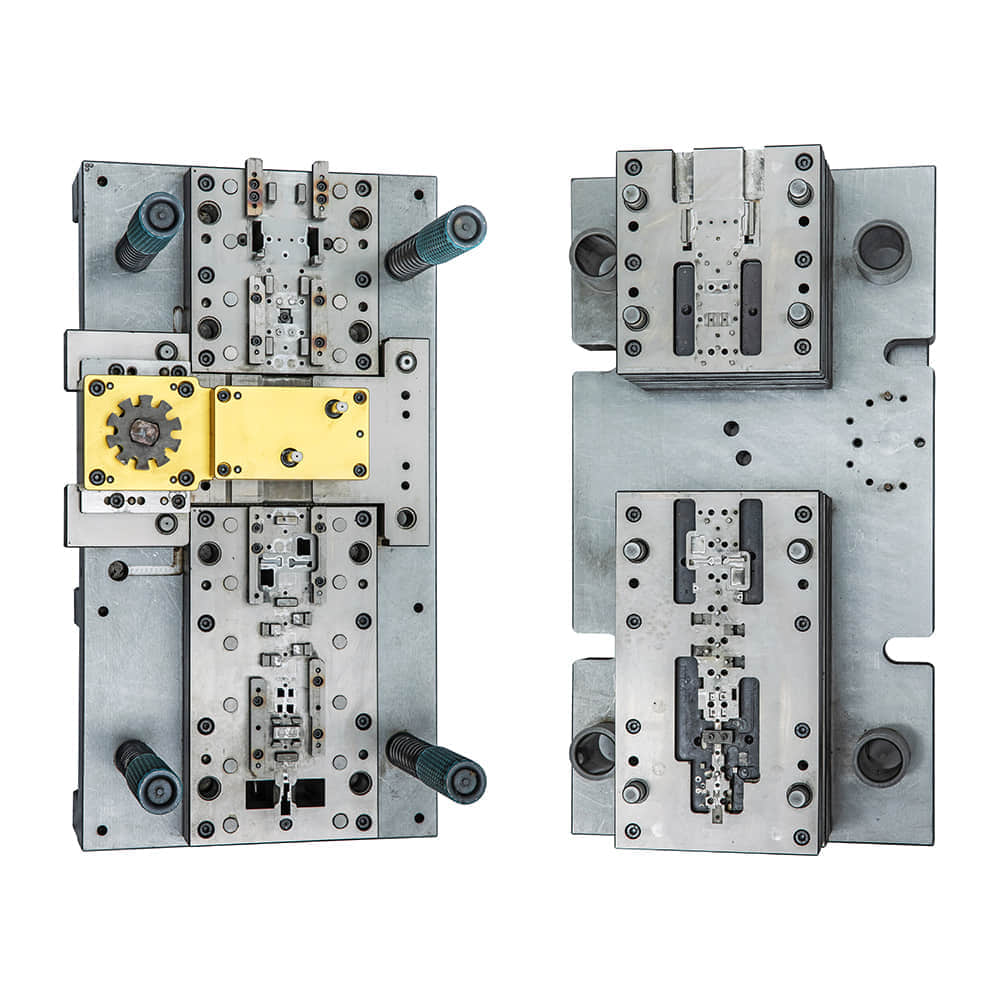

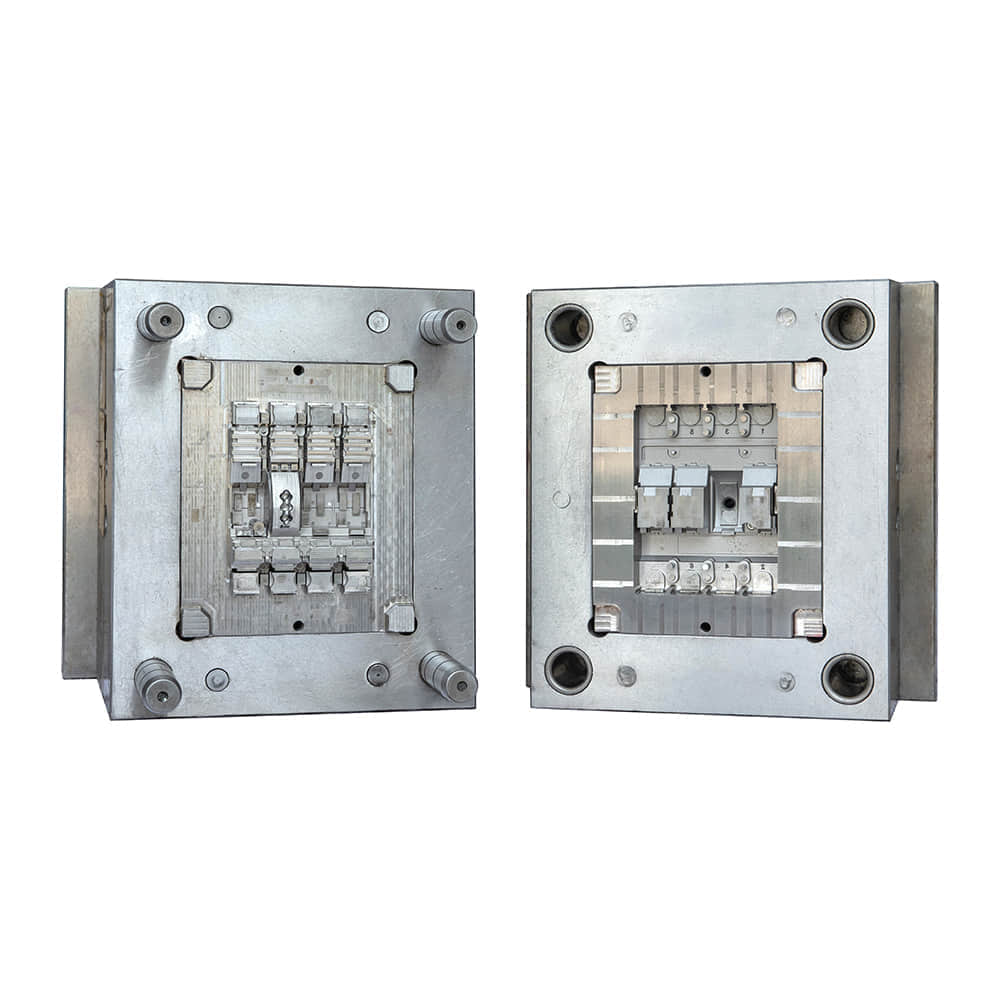

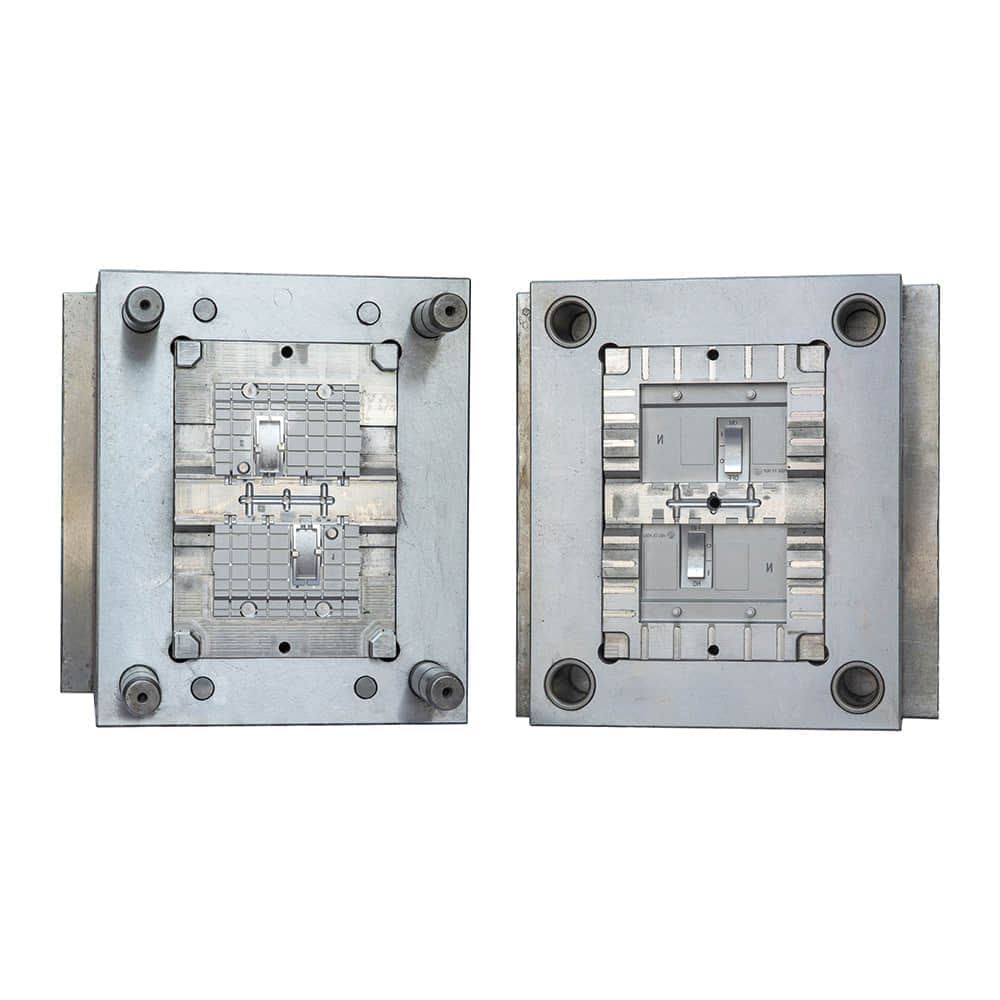

Electronic molded case circuit breakers, often referred to as MCCBs, serve as indispensable guardians of electrical circuits. These devices are designed to interrupt the flow of electricity when it exceeds safe levels, preventing equipment damage, fires, and electrical hazards. Historically, MCCBs have been primarily mechanical in operation. However, modern technology has ushered in a new era of electronic MCCBs, offering enhanced features and performance. 2. Improved Sensing and Protection One of the key innovations in electronic MCCB manufacturing is the incorporation of advanced sensors and protection mechanisms. Traditional MCCBs rely on mechanical tripping mechanisms that may wear down over time. In contrast, electronic MCCBs employ microprocessors and sensors to monitor current and voltage levels continuously. This real-time monitoring allows for precise and instantaneous responses to overcurrent conditions, increasing the overall safety of electrical systems. 3. Customizable Settings Manufacturers have recognized the importance of customization in electronic MCCBs. These devices now come equipped with adjustable trip settings, enabling users to fine-tune the protection parameters according to the specific requirements of their applications. This level of flexibility ensures that electronic MCCBs can be seamlessly integrated into various industries, from manufacturing plants to residential buildings. 4. Remote Monitoring and Control In the age of the Internet of Things (IoT), electronic MCCB manufacturers have embraced connectivity as a fundamental feature. Through remote monitoring and control capabilities, users can access real-time data and make adjustments to MCCB settings from anywhere in the world. This remote accessibility not only enhances convenience but also enables proactive maintenance and troubleshooting. 5. Energy Efficiency Efficiency is a paramount concern in today’s environmentally conscious world. Electronic MCCBs contribute to energy efficiency through intelligent load management. These devices can identify non-critical loads and shed them during peak demand periods, helping to reduce energy consumption and lower utility bills for both commercial and residential users. 6. Enhanced Safety Features Safety remains a top priority in electronic MCCB design. Manufacturers have introduced features such as arc fault detection and ground fault protection to mitigate fire risks and prevent electric shock incidents. These innovations provide an additional layer of safety, especially in environments where electrical faults can have severe consequences. 7. Compact and Space-Saving Designs Space constraints are a common challenge in many applications. To address this issue, electronic MCCB manufacturers have developed compact and modular designs that allow for more efficient use of available space. These smaller footprints make them ideal for installations in crowded electrical panels and enclosures. 8. Environmental Sustainability In recent years, environmental sustainability has become a focal point for electronic MCCB manufacturers. Many now prioritize the use of eco-friendly materials and manufacturing processes, reducing their carbon footprint. Additionally, some models incorporate energy-efficient components to further promote sustainability. 9. Conclusion The world of electronic molded case circuit breakers is evolving at a remarkable pace, driven by manufacturers’ commitment to innovation and safety. These devices have come a long way from their mechanical counterparts, offering enhanced protection, flexibility, and connectivity. As technology continues to advance, we can expect even more groundbreaking developments in electronic MCCB manufacturing, further improving the reliability and efficiency of electrical systems across industries.