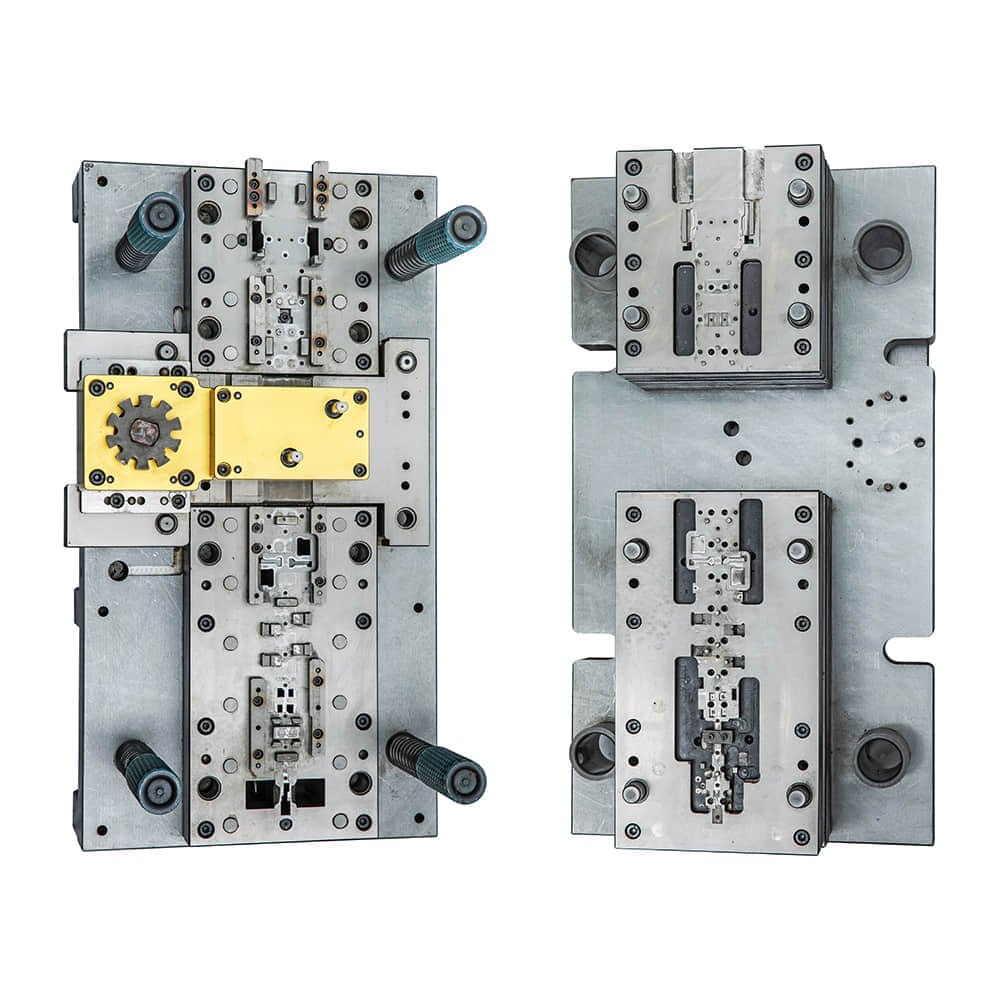

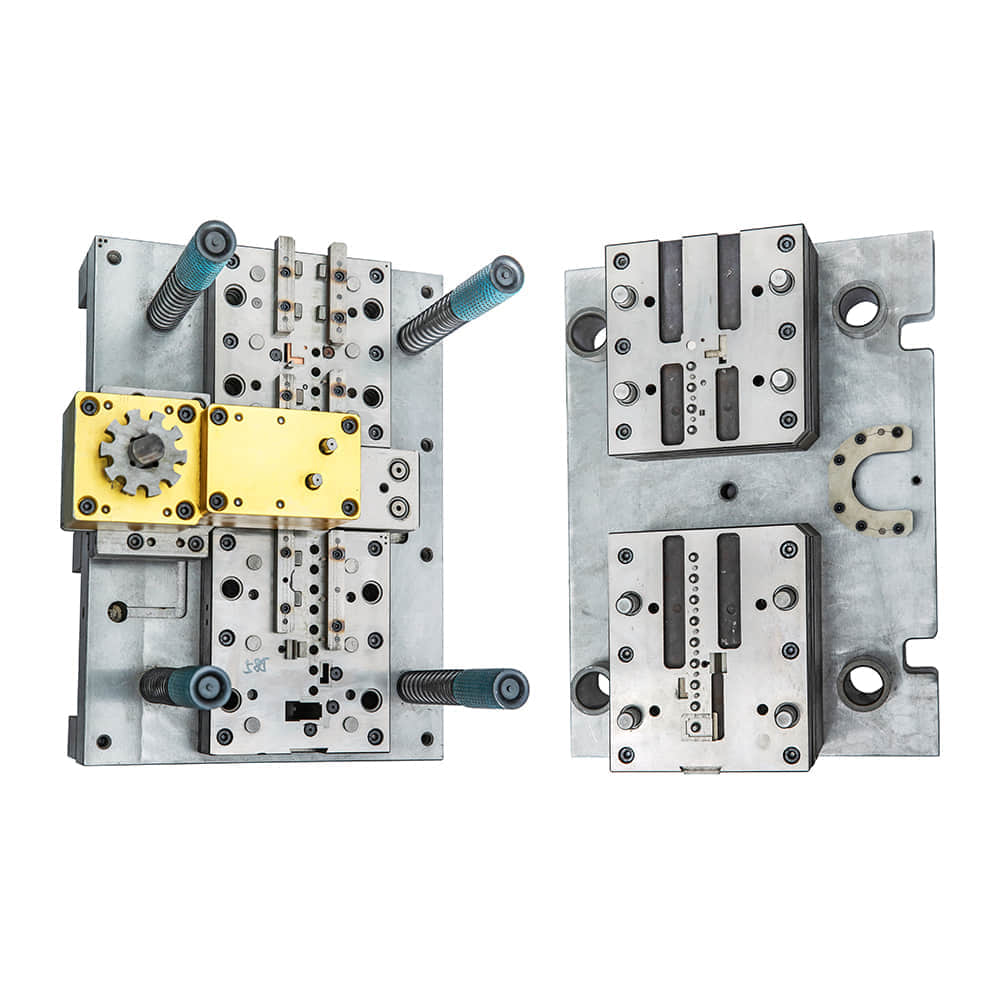

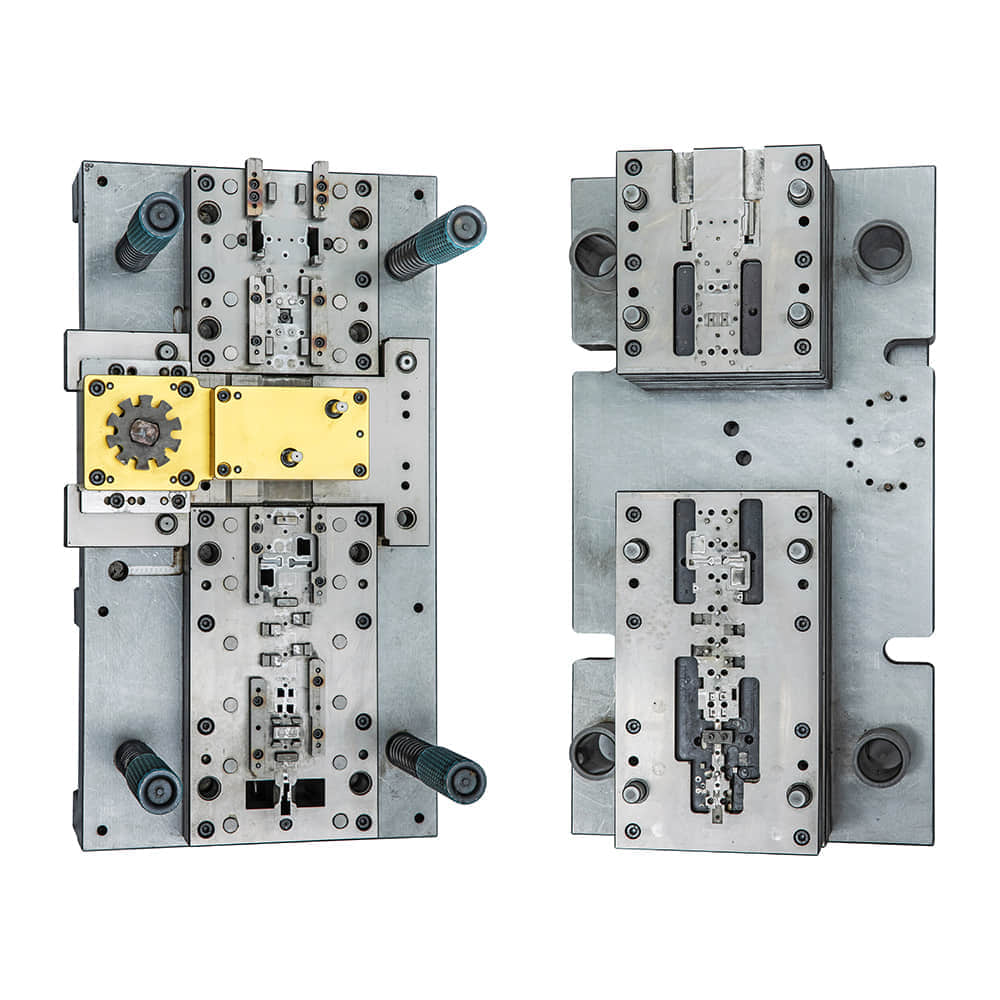

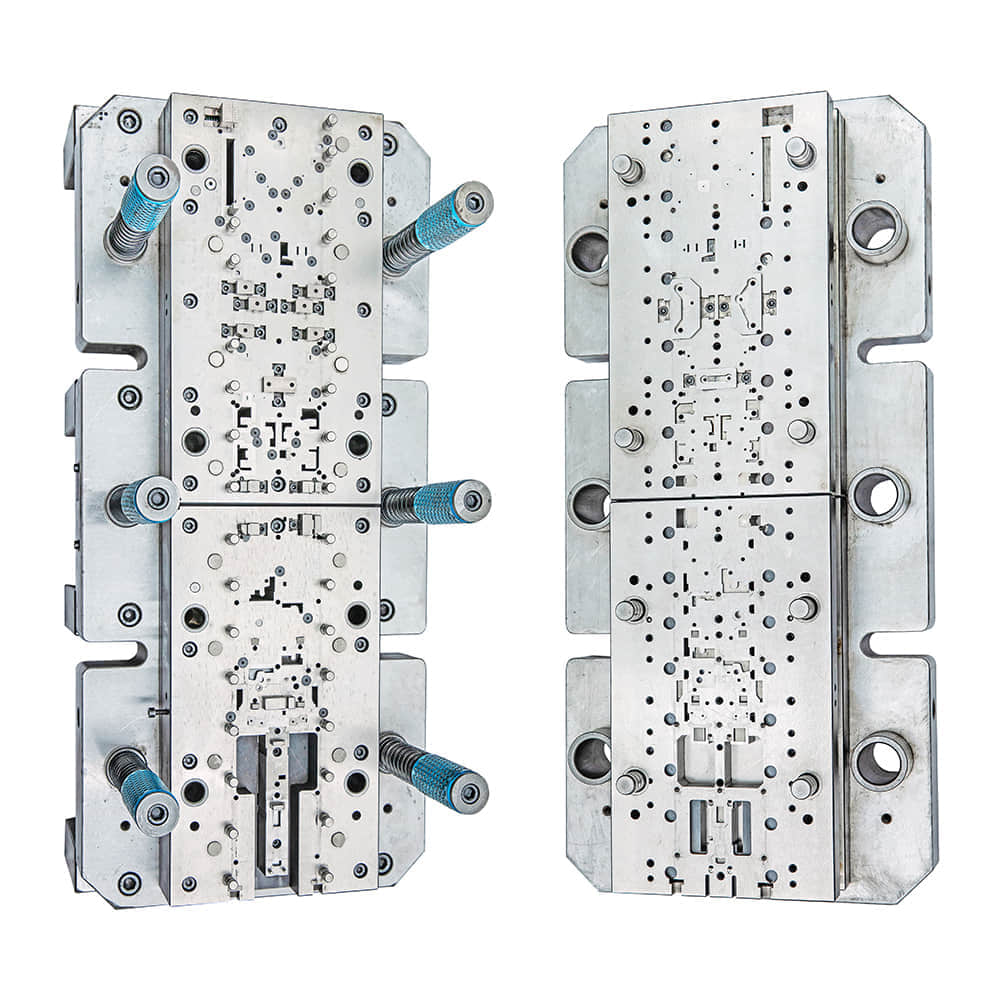

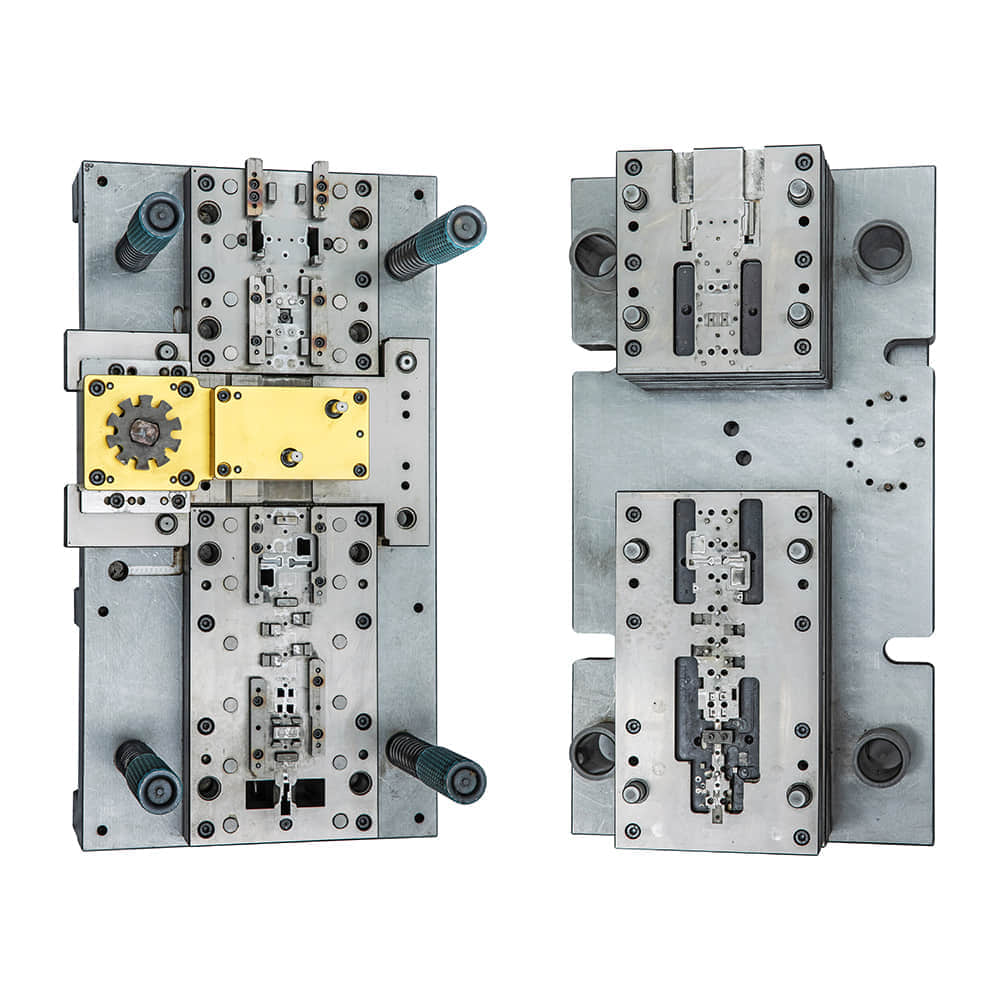

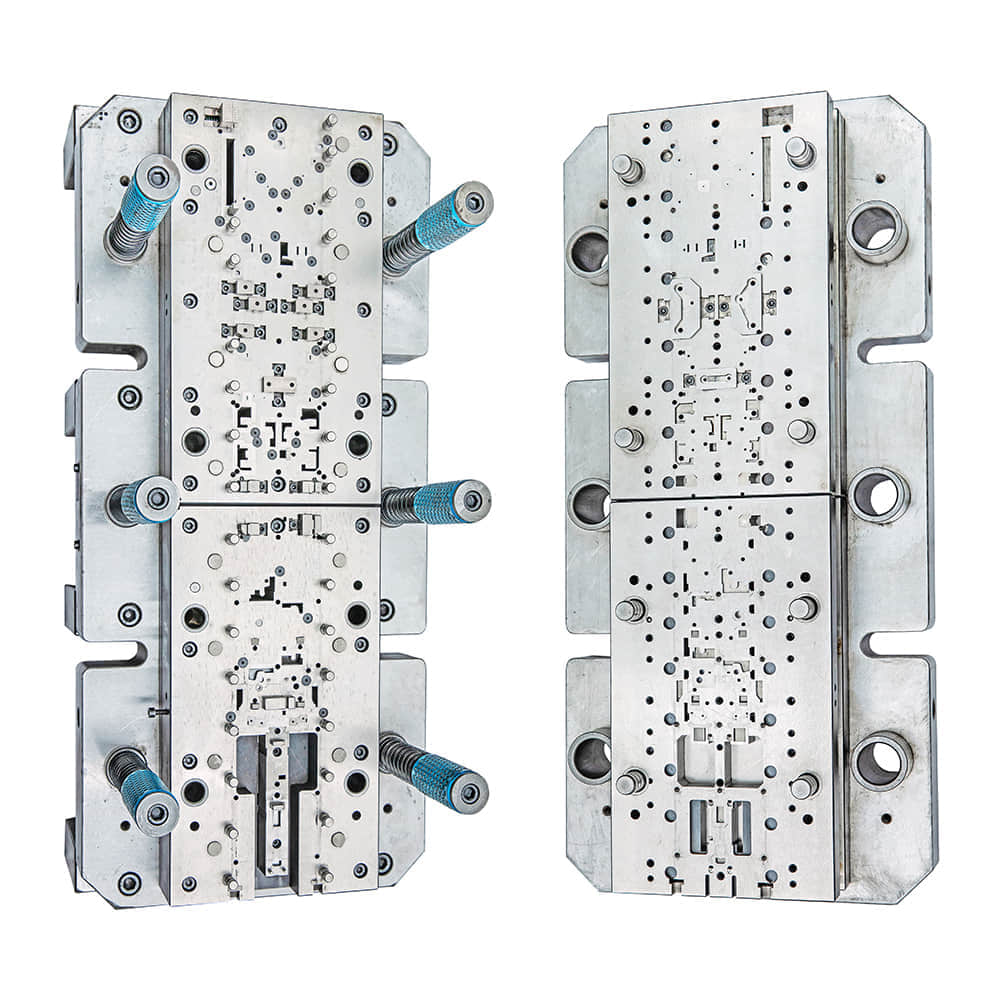

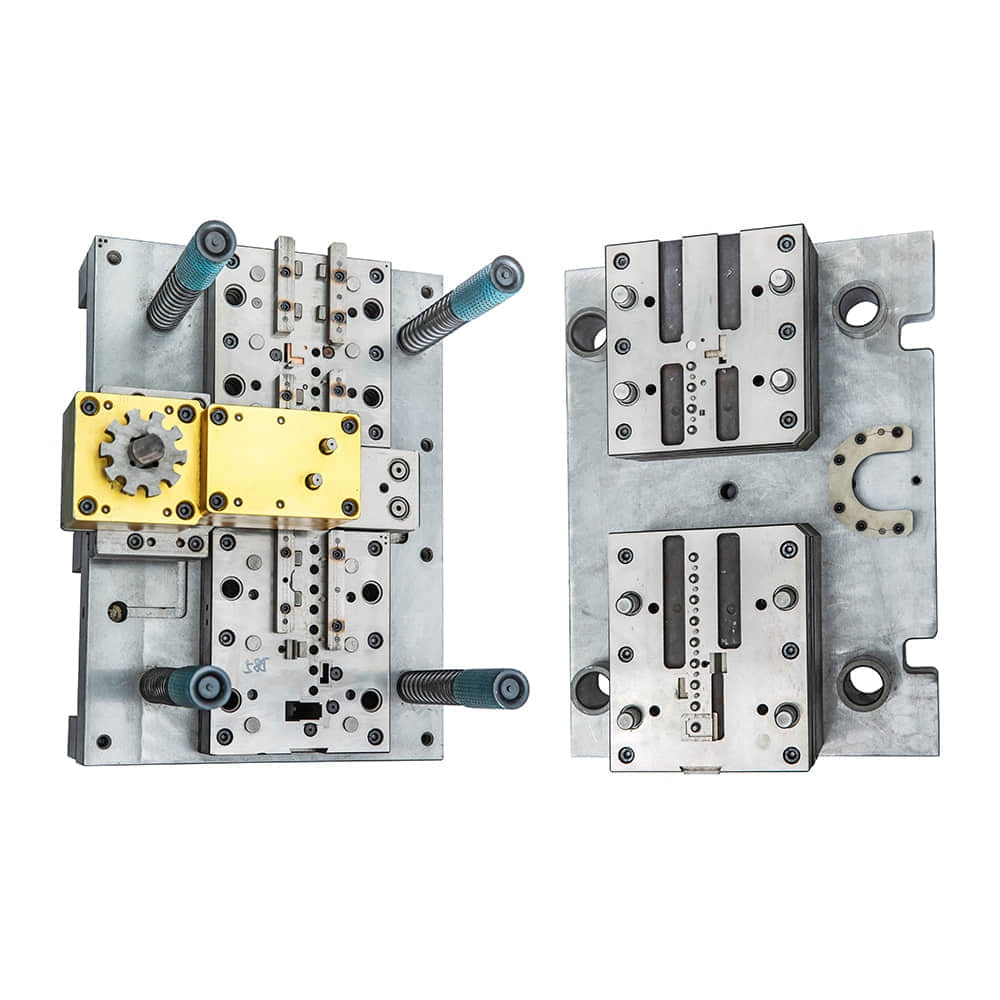

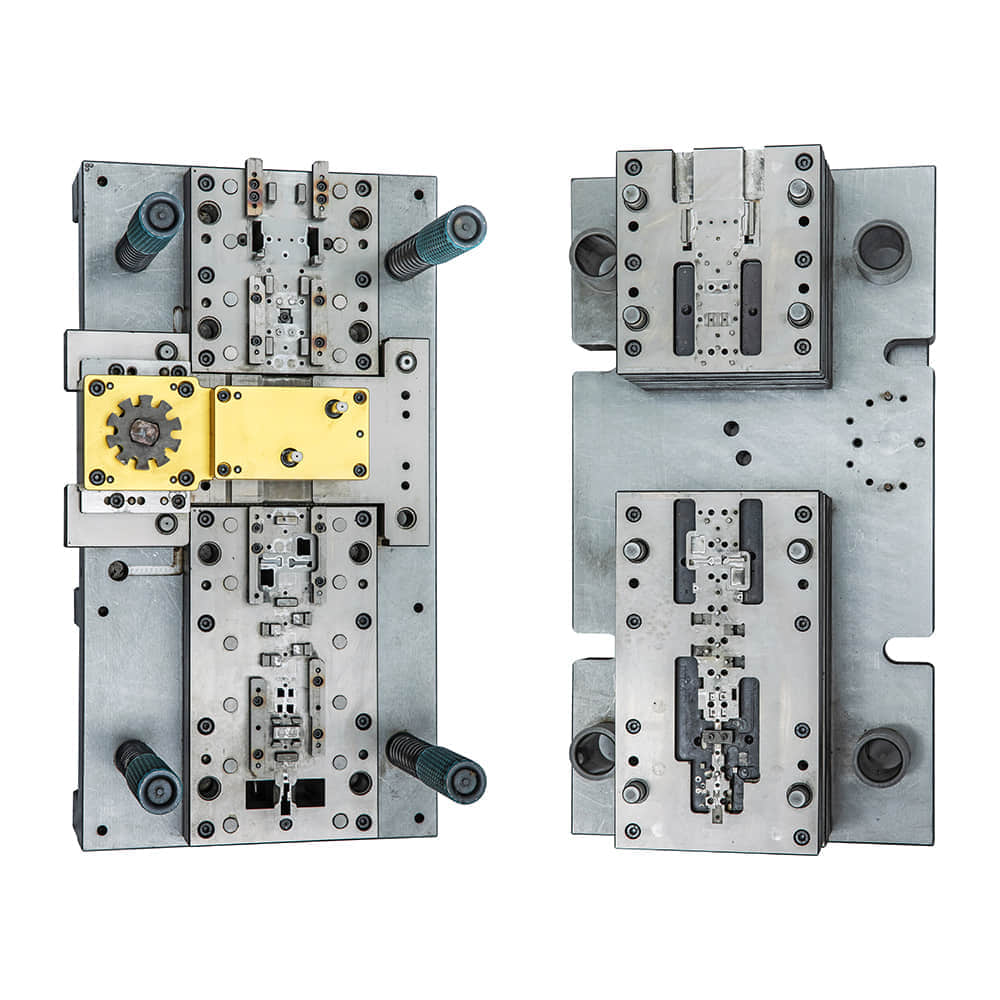

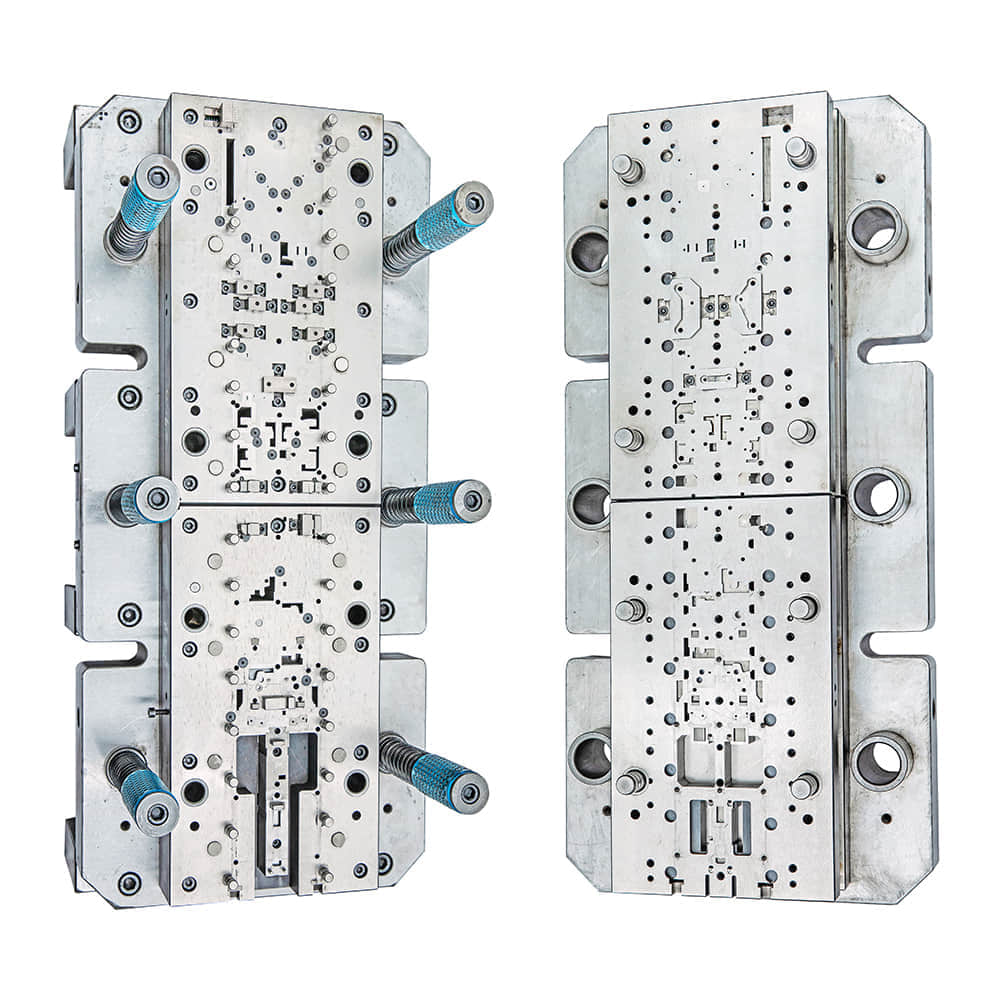

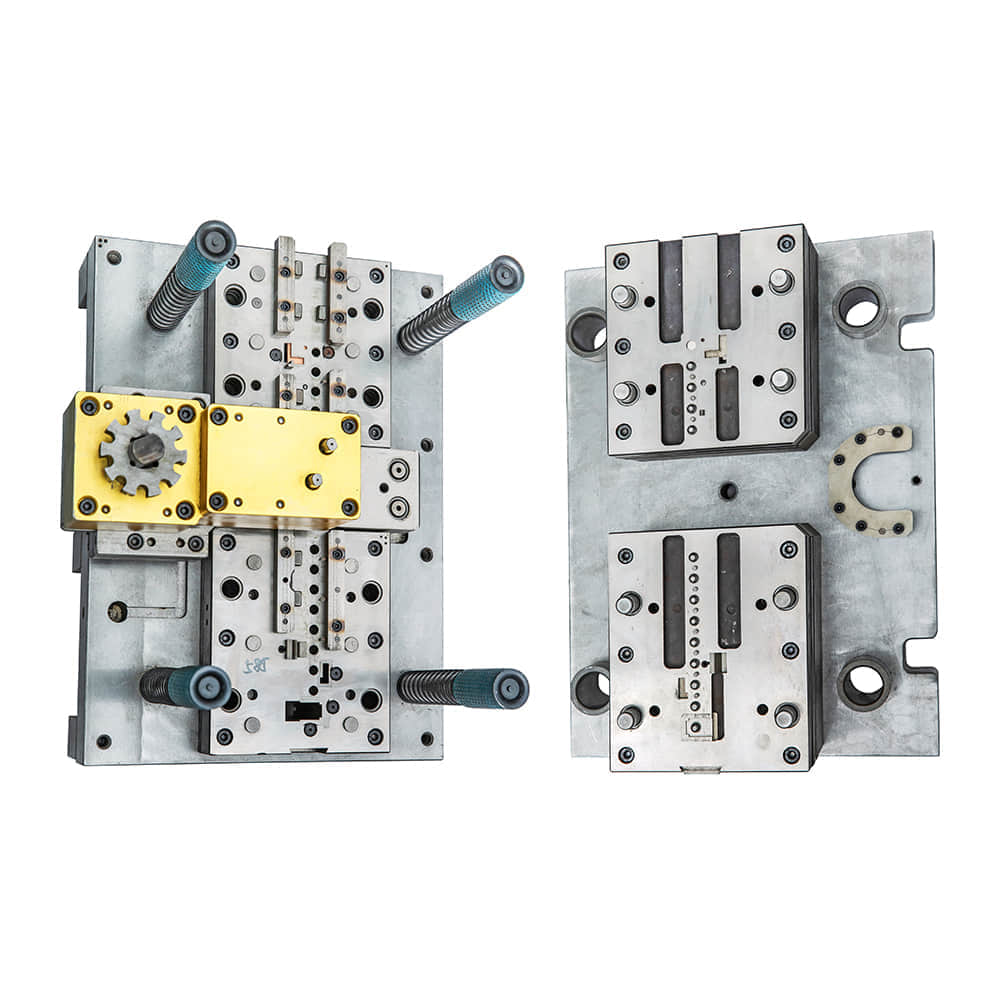

In the world of manufacturing, precision, innovation, and quality are paramount. One industry that exemplifies these principles is metal stamping, and at its core are Metal Stamping Die OEM Manufacturers. These specialized companies play a pivotal role in various industries, from automotive to electronics, by producing the critical tooling required for metal stamping processes. In this article, we will delve into the world of Metal Stamping Die OEM Manufacturers, exploring their significance, processes, and the role they play in shaping our modern world.

The Essence of Metal Stamping Die OEM Manufacturers

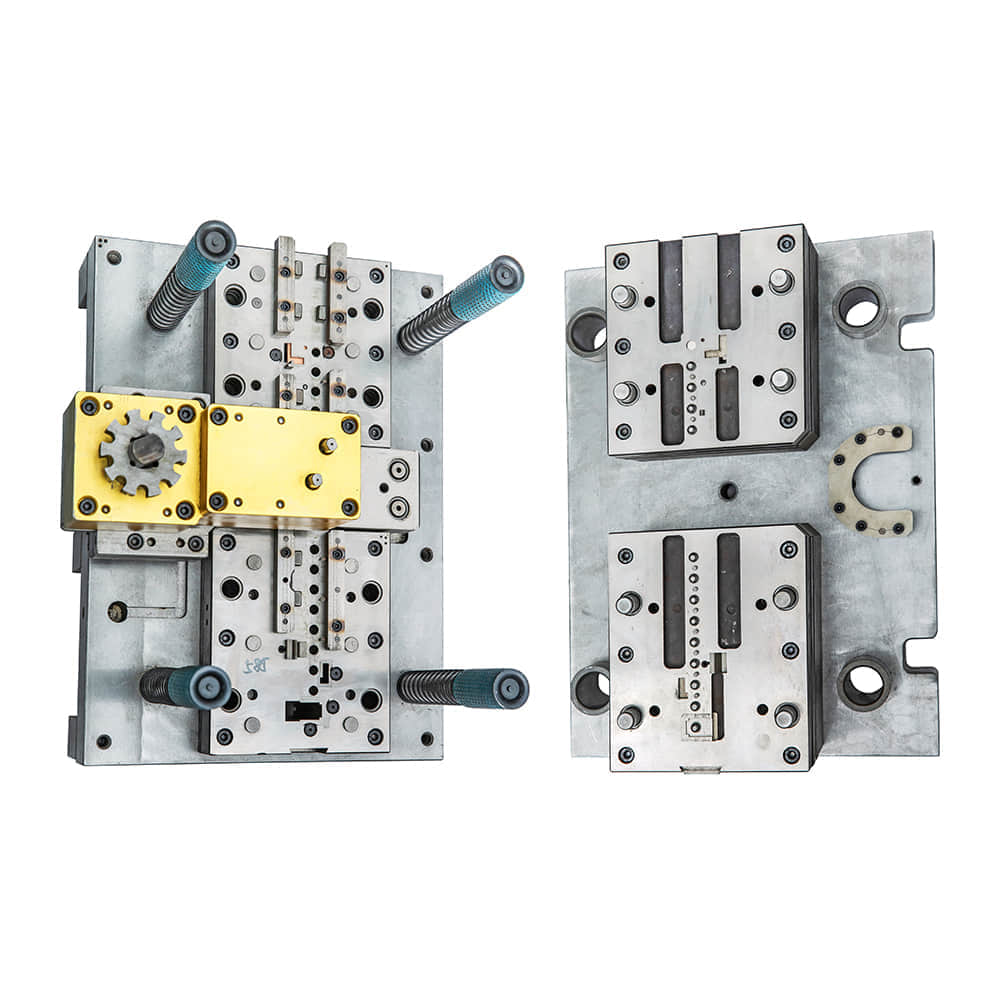

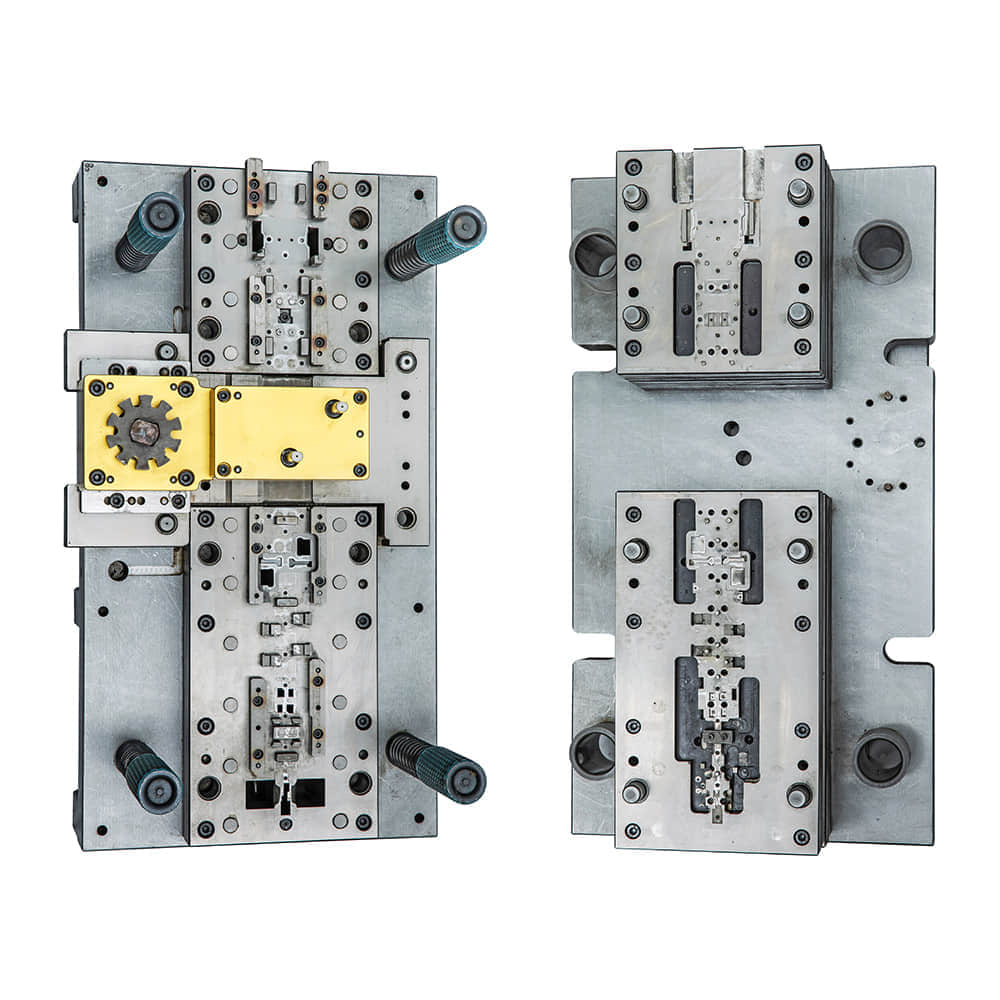

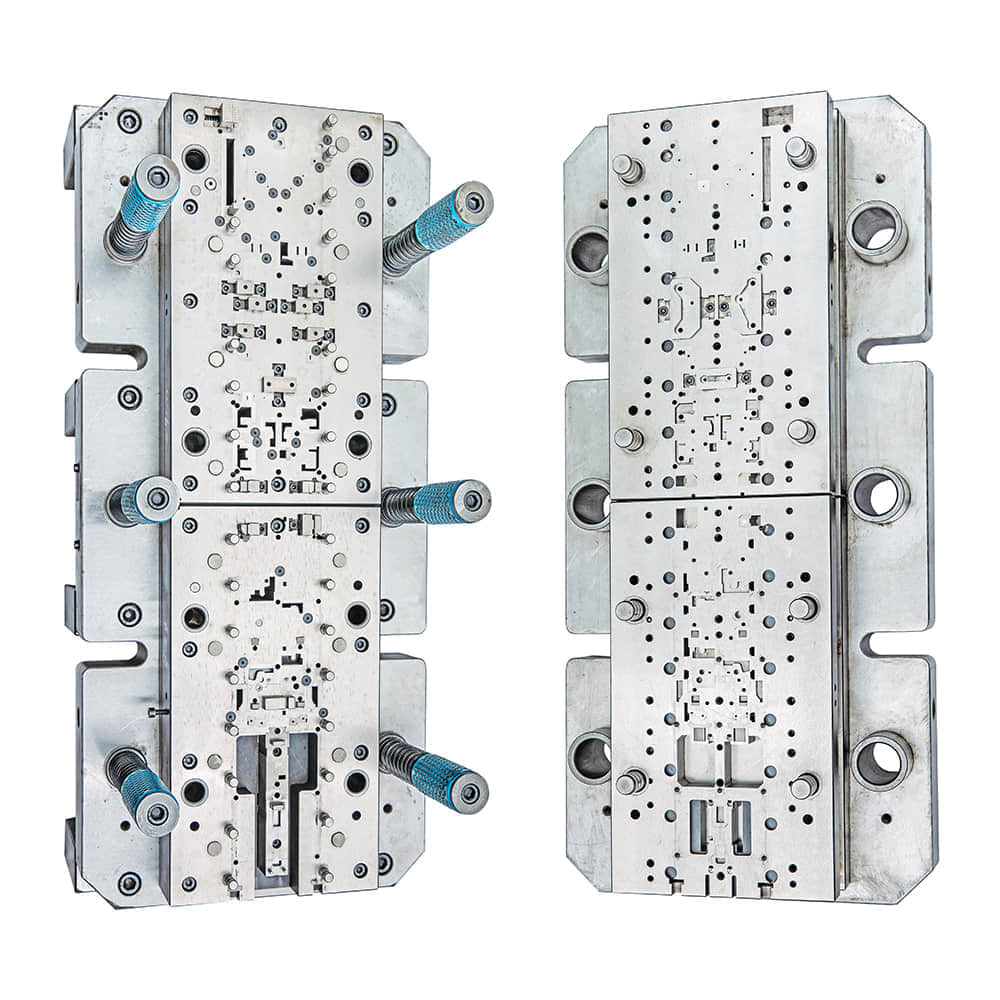

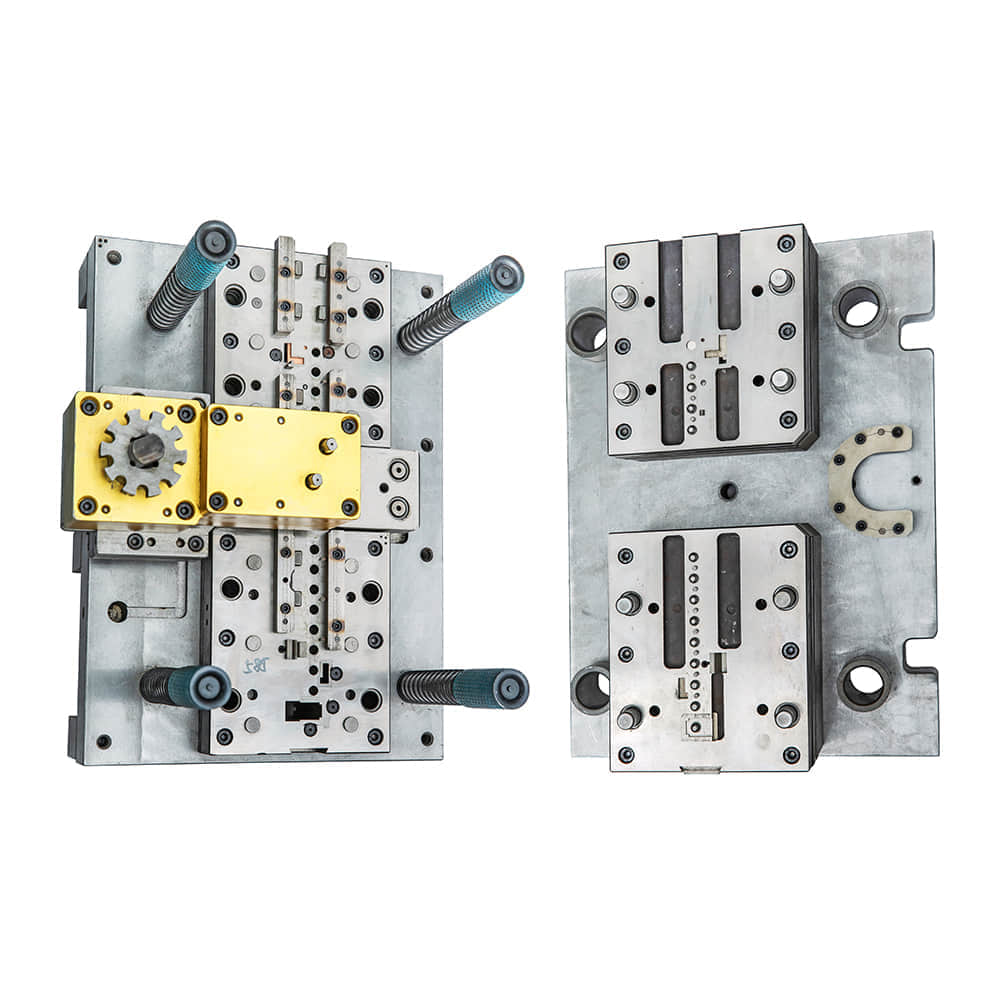

Metal stamping is a versatile and cost-effective method for producing large quantities of complex metal parts with high precision. It’s used to create components found in everyday items, such as car parts, electrical connectors, and consumer electronics. At the heart of metal stamping lies the stamping die, a crucial tool that shapes, cuts, and forms metal into desired shapes. Metal Stamping Die OEM Manufacturers are the unsung heroes behind these critical components. Precision: The Cornerstone of Excellence Precision is the cornerstone of Metal Stamping Die OEM Manufacturers. These companies invest heavily in cutting-edge technology and employ skilled craftsmen to ensure the highest degree of precision in every die they produce. Precision is not just about accuracy; it’s also about consistency. The dies must deliver the same level of quality and precision across thousands or even millions of stamped parts. Innovation: Meeting Evolving Needs Innovation is another driving force in the world of Metal Stamping Die OEM Manufacturers. With evolving industry demands and the constant quest for efficiency, these companies are always on the lookout for innovative solutions. From advanced materials and coatings to improved die designs and manufacturing techniques, innovation is vital to stay competitive in the global market. Quality: A Non-Negotiable Standard Quality is non-negotiable in the world of metal stamping. Inferior dies can lead to costly defects, production delays, and even safety concerns. Metal Stamping Die OEM Manufacturers adhere to stringent quality control processes to ensure that every die meets or exceeds industry standards. This commitment to quality is what makes their products indispensable to various industries. The Role in Shaping Modern Industries Metal Stamping Die OEM Manufacturers play a significant role in shaping modern industries. Here’s a glimpse of their impact in a few key sectors: Automotive Industry: The automotive sector heavily relies on metal stamping for manufacturing vehicle components. From engine parts to body panels, Metal Stamping Die OEM Manufacturers contribute to the production of reliable and safe vehicles. Electronics: In the electronics industry, precision is paramount. Metal stamping dies enable the creation of intricate electrical connectors, ensuring reliable connections in devices like smartphones, computers, and more. Aerospace: Aerospace manufacturers demand parts with the highest precision and durability. Metal stamping dies produce components that withstand extreme conditions, contributing to the safety and efficiency of air travel. Medical Devices: The medical field benefits from metal stamping for the production of surgical instruments, implantable devices, and other critical components. Precision and quality are essential to ensure patient well-being. Conclusion: The Unsung Heroes In conclusion, Metal Stamping Die OEM Manufacturers are the unsung heroes behind many of the products we rely on daily. Their commitment to precision, innovation, and quality ensures that industries worldwide can produce high-quality, reliable, and safe products. As technology continues to advance, Metal Stamping Die OEM Manufacturers will remain at the forefront, shaping our modern world one precision die at a time.