In the realm of modern electrical systems, the frame circuit breaker fixed switch plays a pivotal role in ensuring the safety and reliability of power distribution. Behind this crucial component, Original Equipment Manufacturers (OEMs) stand as key players, driving innovation, quality, and technological advancement in the industry.

The Significance of Frame Circuit Breaker Fixed Switches

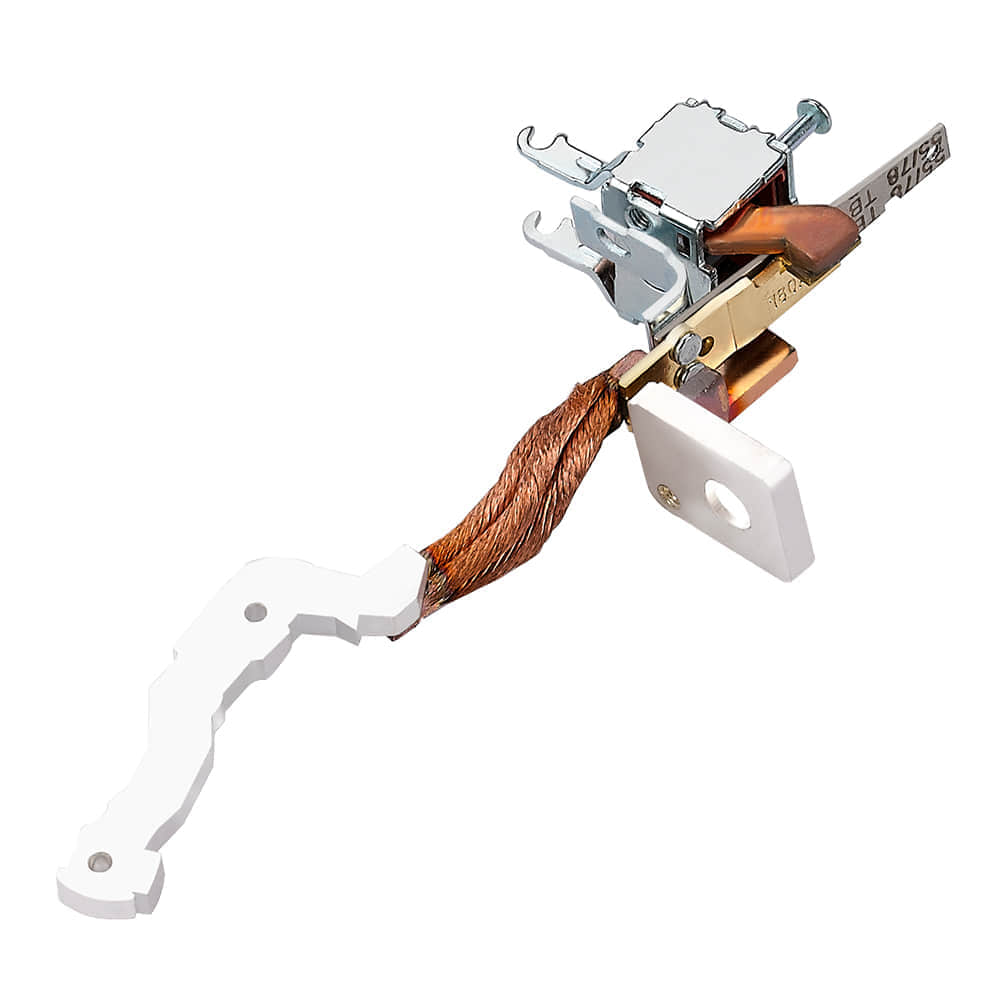

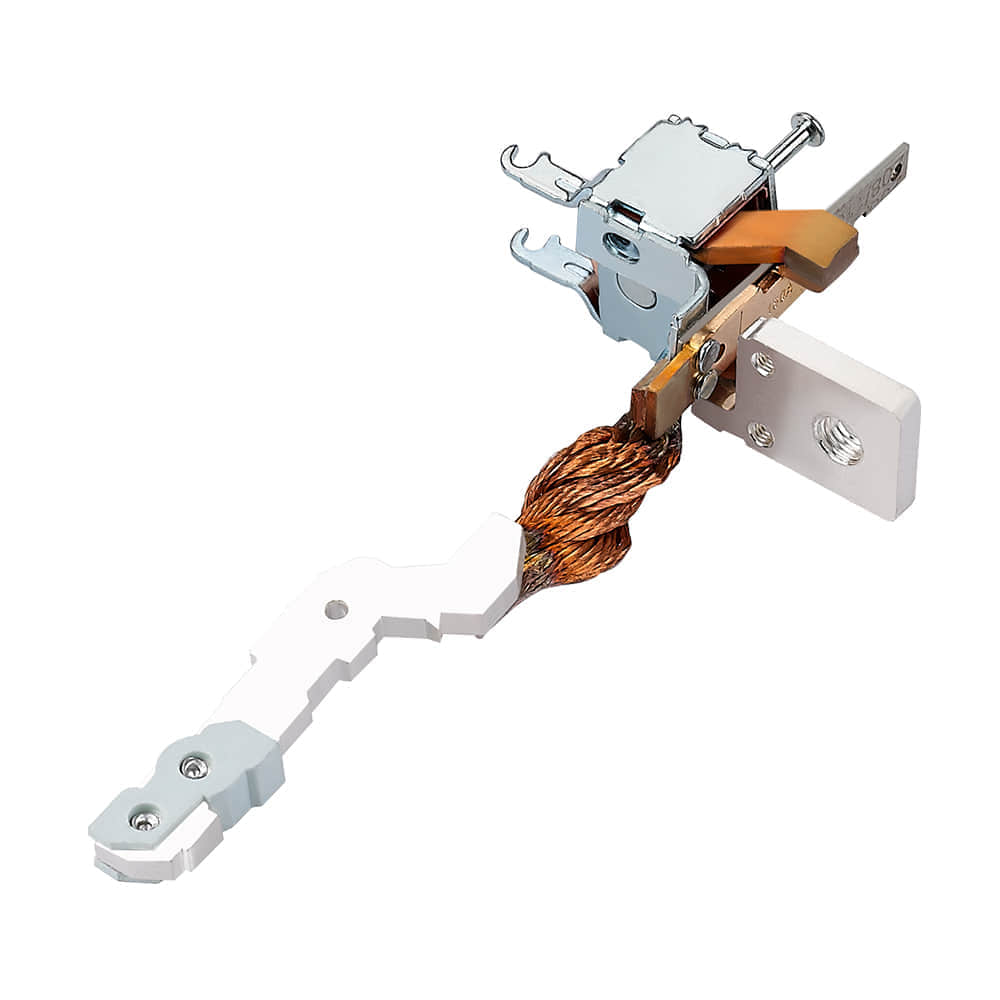

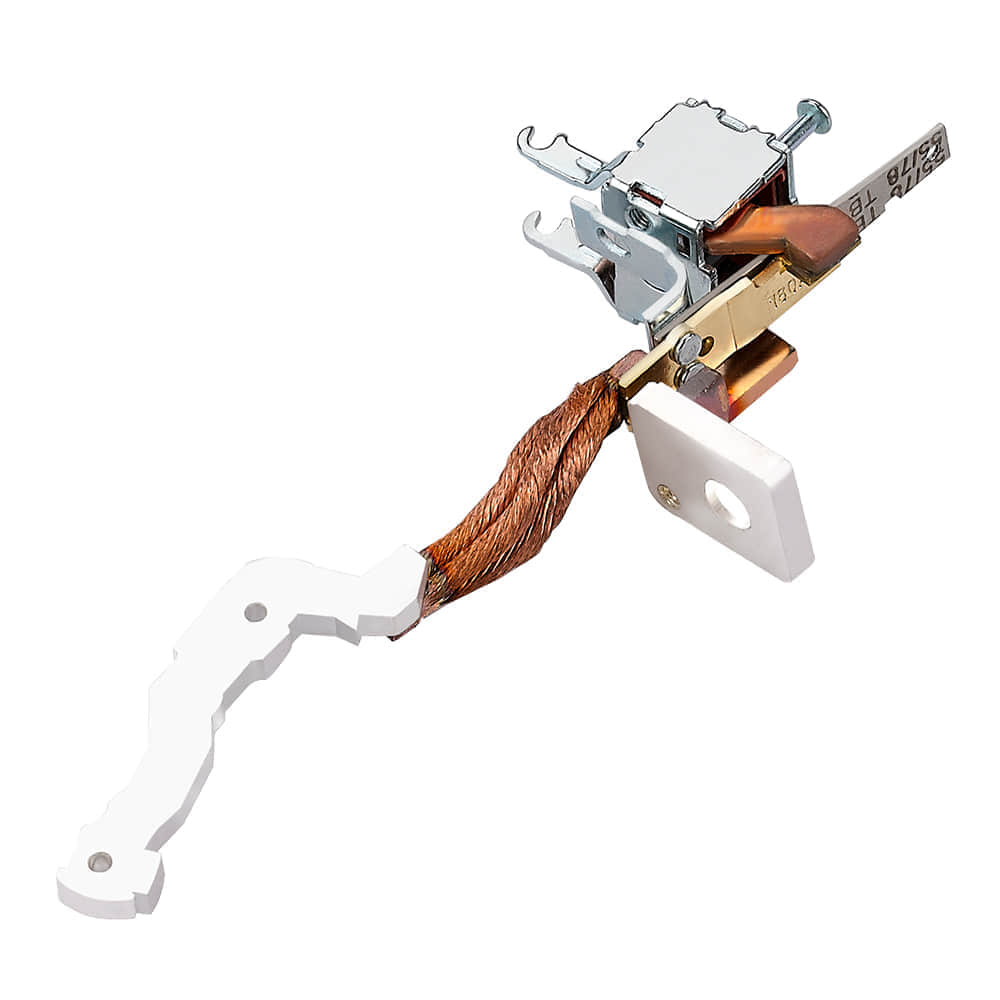

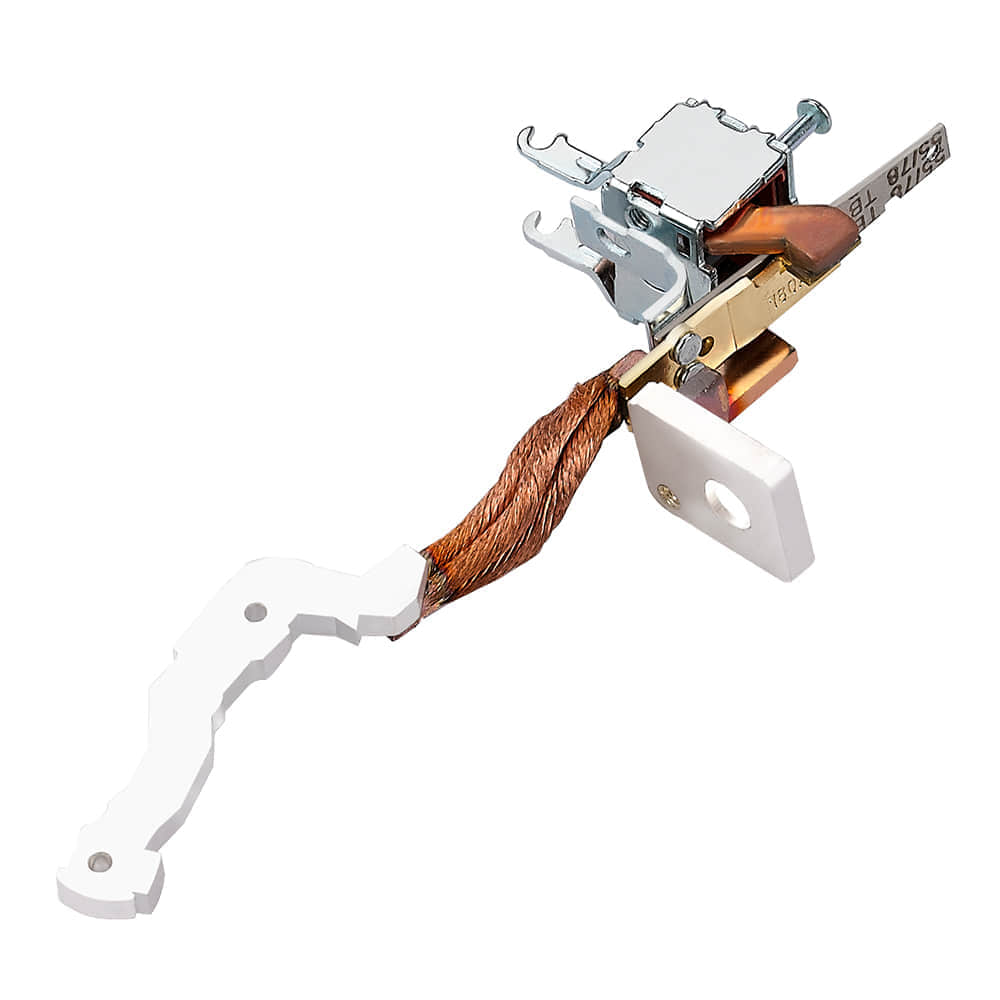

Frame circuit breaker fixed switches are integral parts of electrical distribution systems. These switches are designed to control the flow of electricity, interrupting or diverting it when necessary to prevent overloads, short circuits, and other electrical faults that could lead to damage, fires, or even life-threatening situations. Their importance in safeguarding both infrastructure and human life cannot be overstated. OEM Manufacturers: Pioneers of Quality and Innovation OEM manufacturers play a vital role in the development and production of frame circuit breaker fixed switches. These companies specialize in producing components that are used in the products of other companies. When it comes to electrical components like circuit breaker fixed switches, OEM manufacturers bring a wealth of expertise and innovation to the table. One of the key advantages of relying on OEM manufacturers is their specialized knowledge. These manufacturers focus exclusively on producing specific components, allowing them to become experts in their respective domains. As a result, OEMs can provide frame circuit breaker fixed switches with exceptional quality, performance, and durability. Innovation in Design and Technology OEM manufacturers are at the forefront of innovation in the field of frame circuit breaker fixed switches. They continuously invest in research and development to create switches that are more efficient, responsive, and adaptable to different operating conditions. This drive for innovation has led to the development of smart switches that can be remotely monitored and controlled, enhancing the overall efficiency and maintenance of electrical systems. Customization and Flexibility OEM manufacturers understand that different industries and applications have unique requirements when it comes to frame circuit breaker fixed switches. These manufacturers offer customization options, allowing their clients to tailor switches according to their specific needs. This level of flexibility ensures that the switches can seamlessly integrate into various systems, promoting compatibility and reliability. Ensuring Quality and Reliability Quality control is a hallmark of reputable OEM manufacturers. To maintain their reputation, these manufacturers implement stringent quality assurance processes throughout the production cycle. This includes rigorous testing, adherence to industry standards, and compliance with safety regulations. The result is frame circuit breaker fixed switches that are not only efficient but also safe for long-term operation. Collaboration with OEM Manufacturers Collaborating with OEM manufacturers for frame circuit breaker fixed switches can be a strategic decision for companies in various industries. By outsourcing the manufacturing of these critical components to experts, companies can focus on their core competencies while ensuring the reliability and performance of their products. Conclusion In the dynamic landscape of electrical systems, frame circuit breaker fixed switches stand as essential guardians of safety and reliability. OEM manufacturers, with their focus on quality, innovation, and customization, play a pivotal role in shaping the capabilities of these switches. Their expertise ensures that electrical systems worldwide can operate with efficiency and confidence, safeguarding both infrastructure and lives.