In the fast-paced world of electrical engineering, safety, reliability, and efficiency are paramount. Meet the MCCB BMC Parts Manufacturer, a driving force behind the scenes, quietly but crucially contributing to the electrical industry. In this article, we will delve into the world of Molded Case Circuit Breaker (MCCB) BMC (Bulk Molding Compound) parts manufacturing, exploring their significance, innovations, and the role they play in shaping the modern electrical landscape.

The Significance of MCCB BMC Parts:

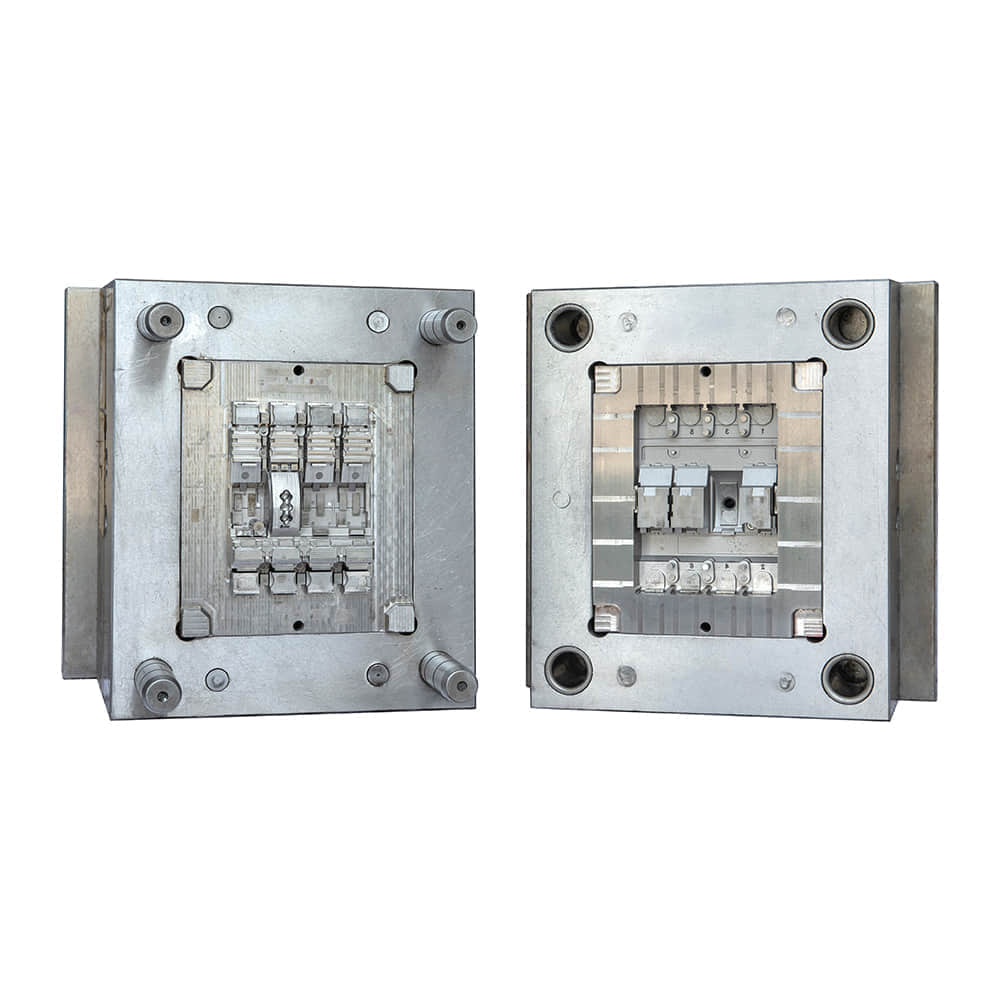

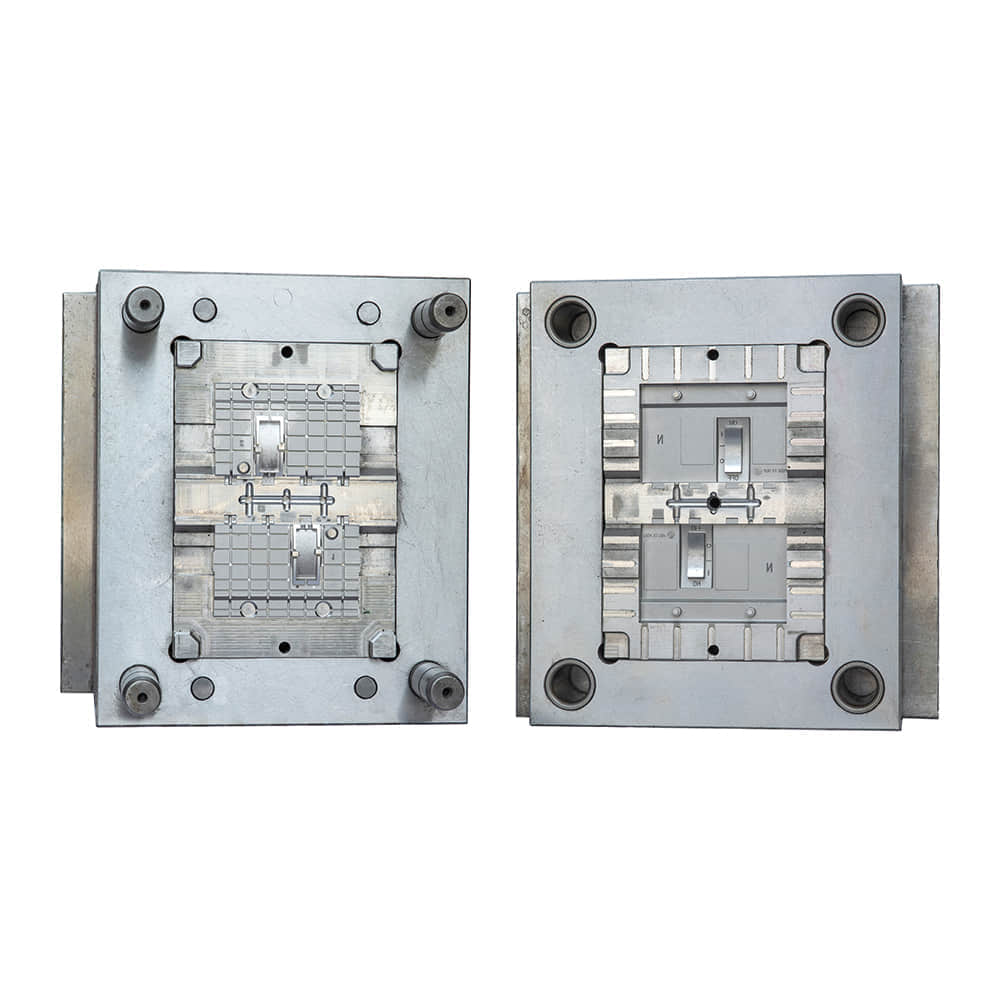

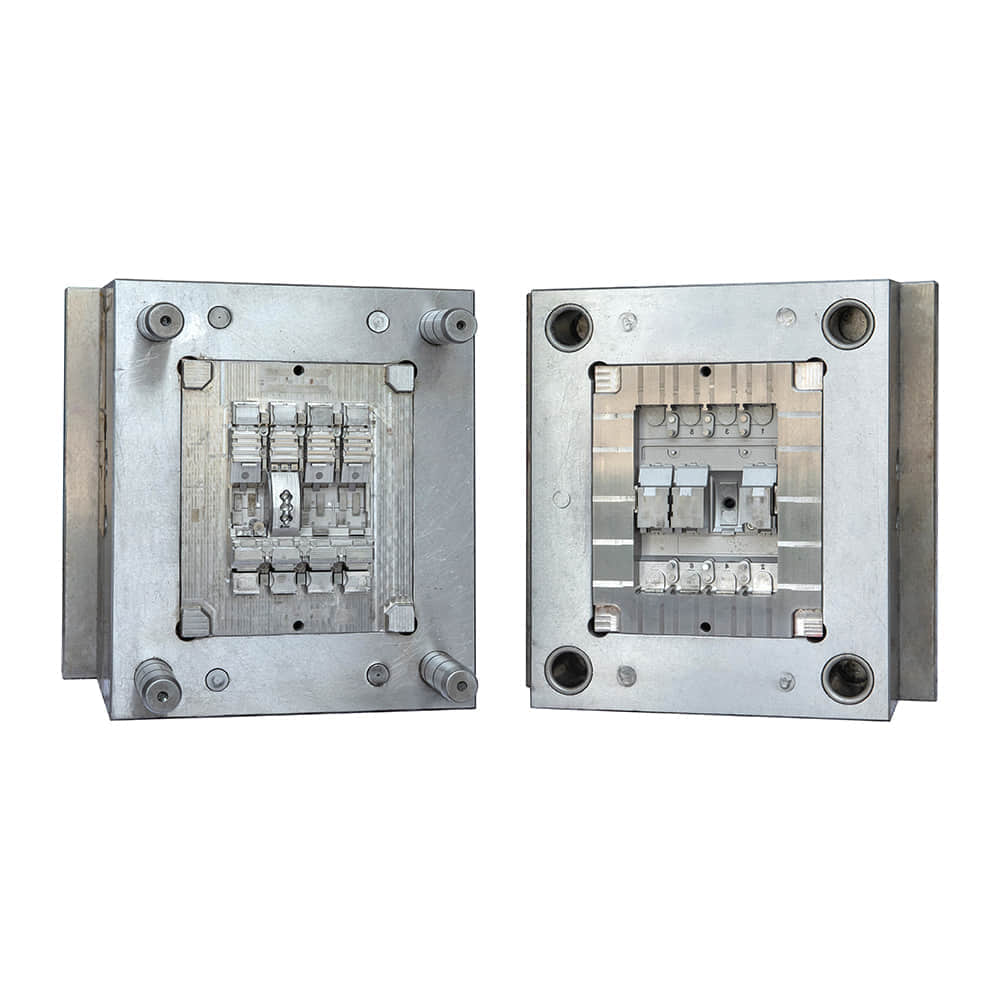

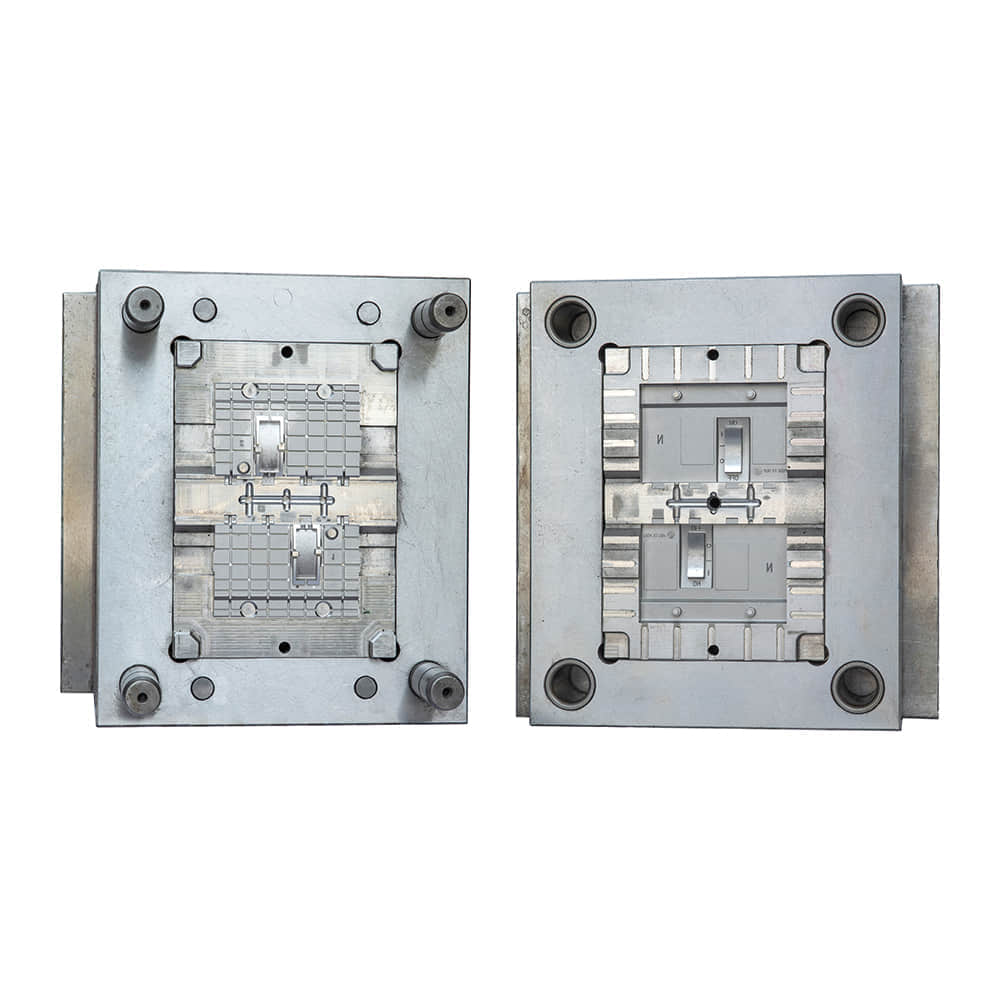

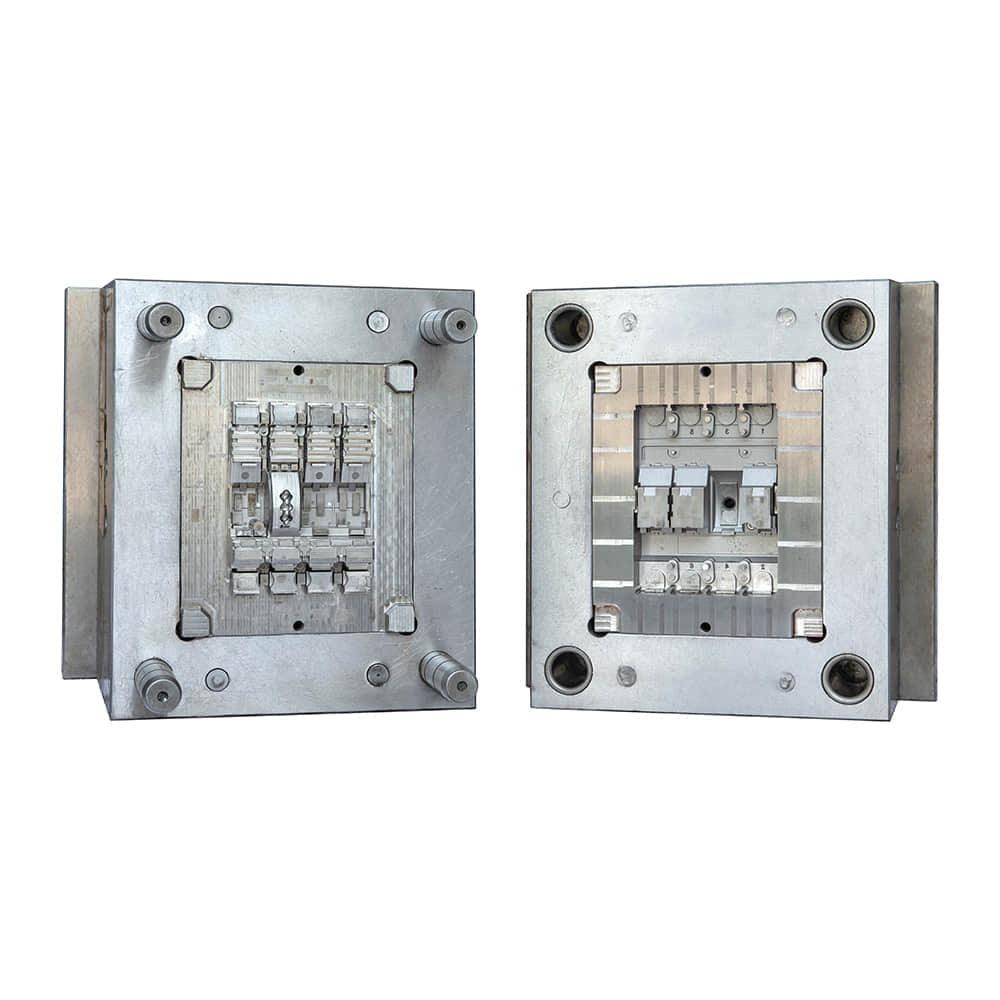

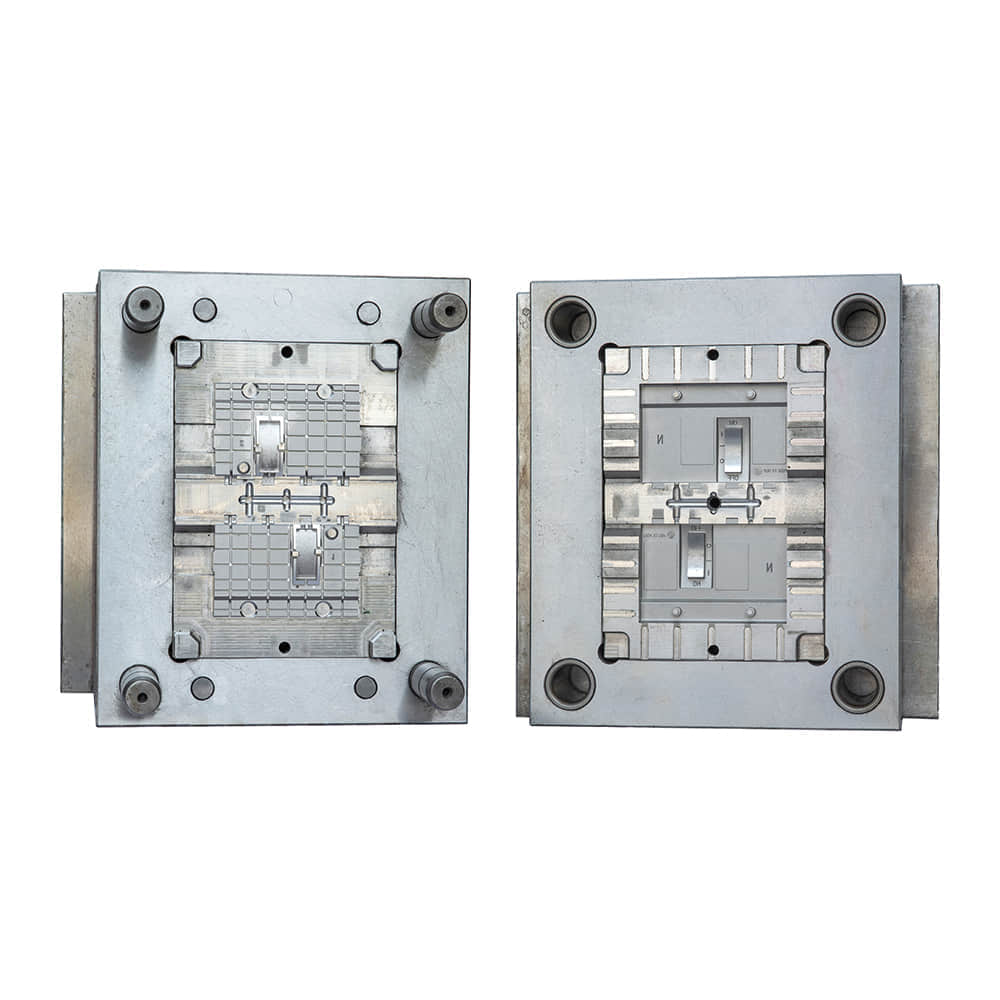

MCCBs are integral components in electrical systems, responsible for safeguarding against overcurrents and short circuits. The robustness and reliability of MCCBs are essential to prevent electrical hazards and ensure uninterrupted power supply. This is where MCCB BMC parts come into play. BMC is a high-strength thermoset composite material known for its exceptional electrical insulation properties, mechanical strength, and flame resistance. These qualities make BMC an ideal material for manufacturing MCCB parts. Innovations in MCCB BMC Parts Manufacturing: Advanced Materials:MCCB BMC parts manufacturers are continually researching and incorporating advanced materials to enhance the performance and durability of their products. This includes the development of BMC formulations that offer better resistance to temperature variations and harsh environments. Precision Engineering:Modern manufacturing techniques, such as Computer Numerical Control (CNC) machining and 3D printing, have revolutionized MCCB BMC parts production. These technologies enable the creation of intricate and precise components, ensuring MCCBs operate flawlessly under various conditions. Customization:One size doesn’t fit all in the electrical industry. MCCB BMC parts manufacturers are increasingly offering customization options to meet the specific needs of their clients. This ensures that MCCBs can be seamlessly integrated into diverse electrical systems. Efficiency and Sustainability:Sustainability is a growing concern, even in the electrical industry. Manufacturers are adopting eco-friendly production methods and recyclable materials, reducing their carbon footprint while maintaining the high-quality standards of their MCCB BMC parts. The Role in Shaping the Modern Electrical Landscape: MCCB BMC parts are the unsung heroes that contribute to the safety and reliability of electrical systems in various sectors, including residential, commercial, and industrial. They play a pivotal role in preventing electrical fires, equipment damage, and downtime, saving lives and resources. The modern electrical landscape demands innovative solutions to accommodate the increasing demands for power distribution and energy efficiency. MCCB BMC parts manufacturers are rising to the challenge by creating components that not only meet current requirements but also anticipate future needs. Conclusion: As technology continues to advance, the electrical industry must adapt to new challenges and demands. MCCB BMC parts manufacturers are at the forefront of this adaptation, consistently pushing the boundaries of what is possible in electrical safety and reliability. Their commitment to innovation and quality ensures that our electrical systems remain secure, efficient, and sustainable, paving the way for a brighter, electrified future.