In the world of manufacturing, precision and quality are paramount. Metal stamping, a versatile and essential process, plays a pivotal role in industries ranging from automotive to electronics. To meet the ever-evolving demands of these sectors, Original Design Manufacturer (ODM) companies specializing in metal stamping parts have become crucial. In this article, we will delve into the significance of Metal Stamping Parts ODM Manufacturers and their role in shaping the industrial landscape.

The Genesis of Metal Stamping Parts ODM Manufacturers

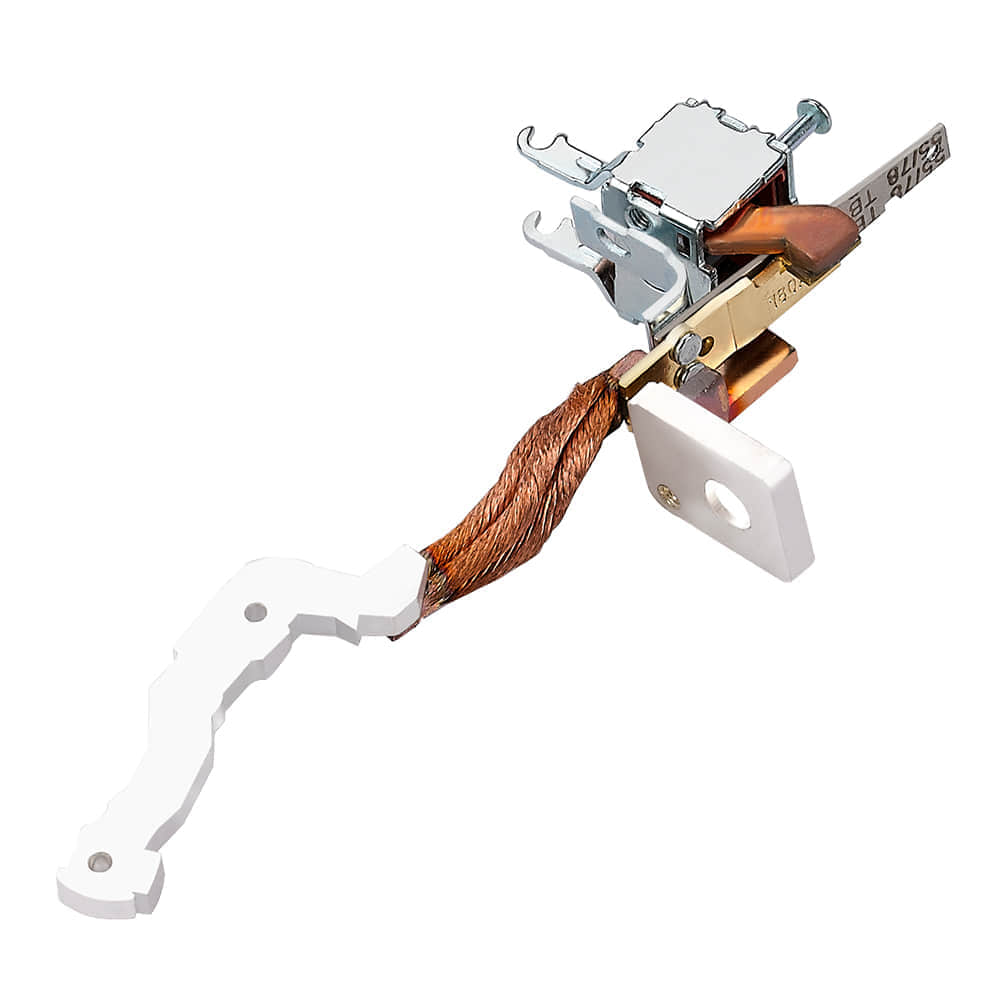

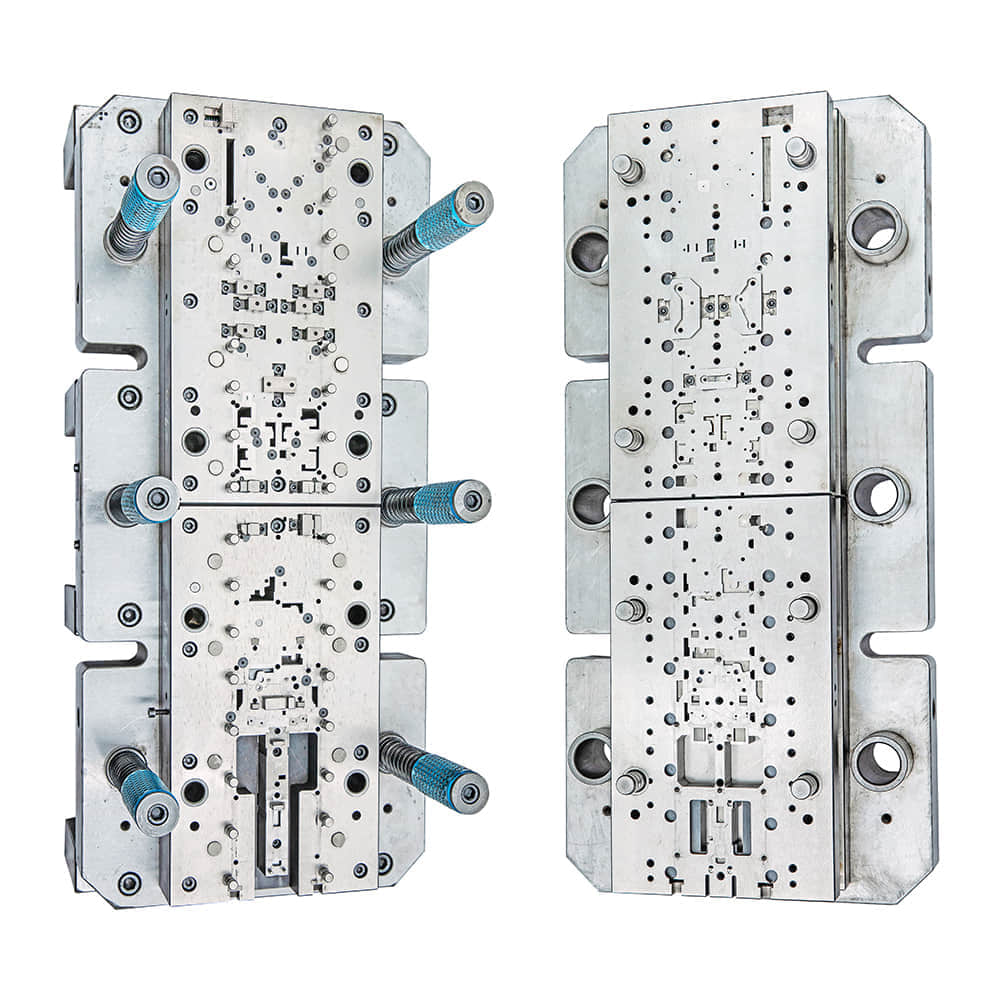

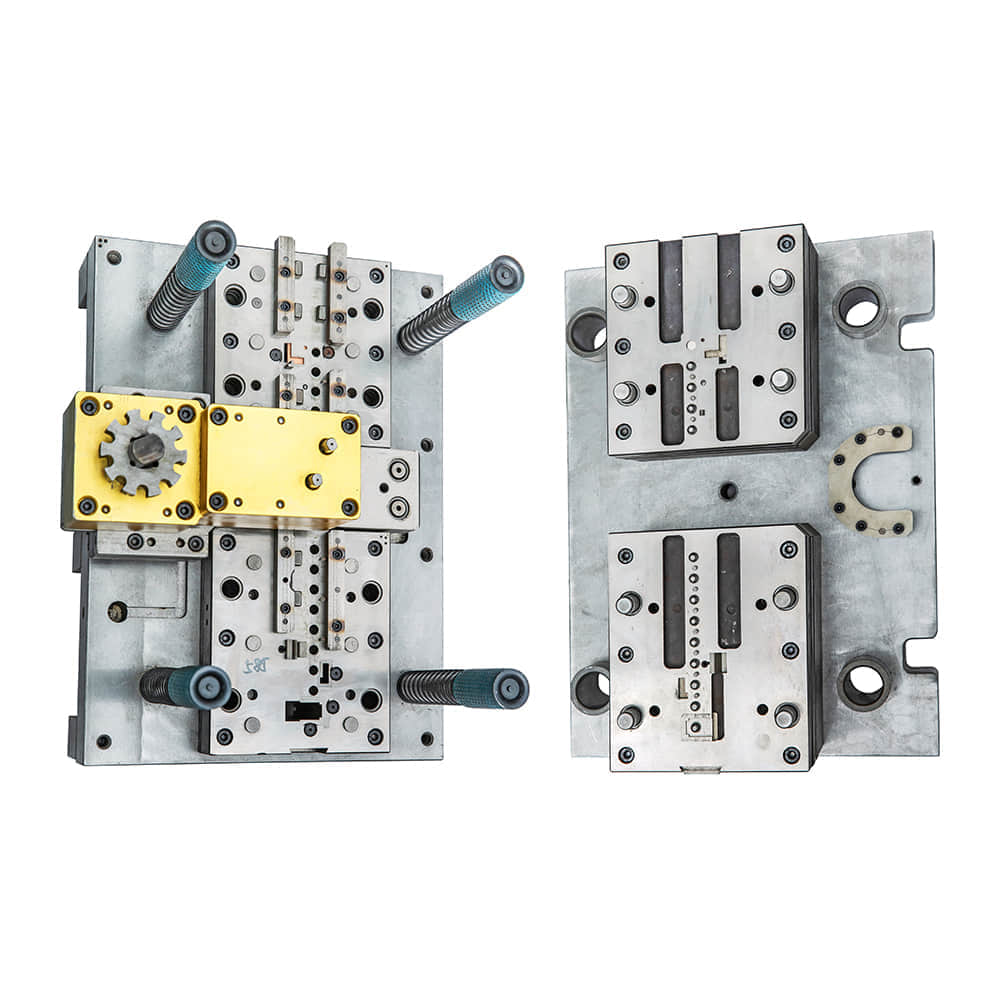

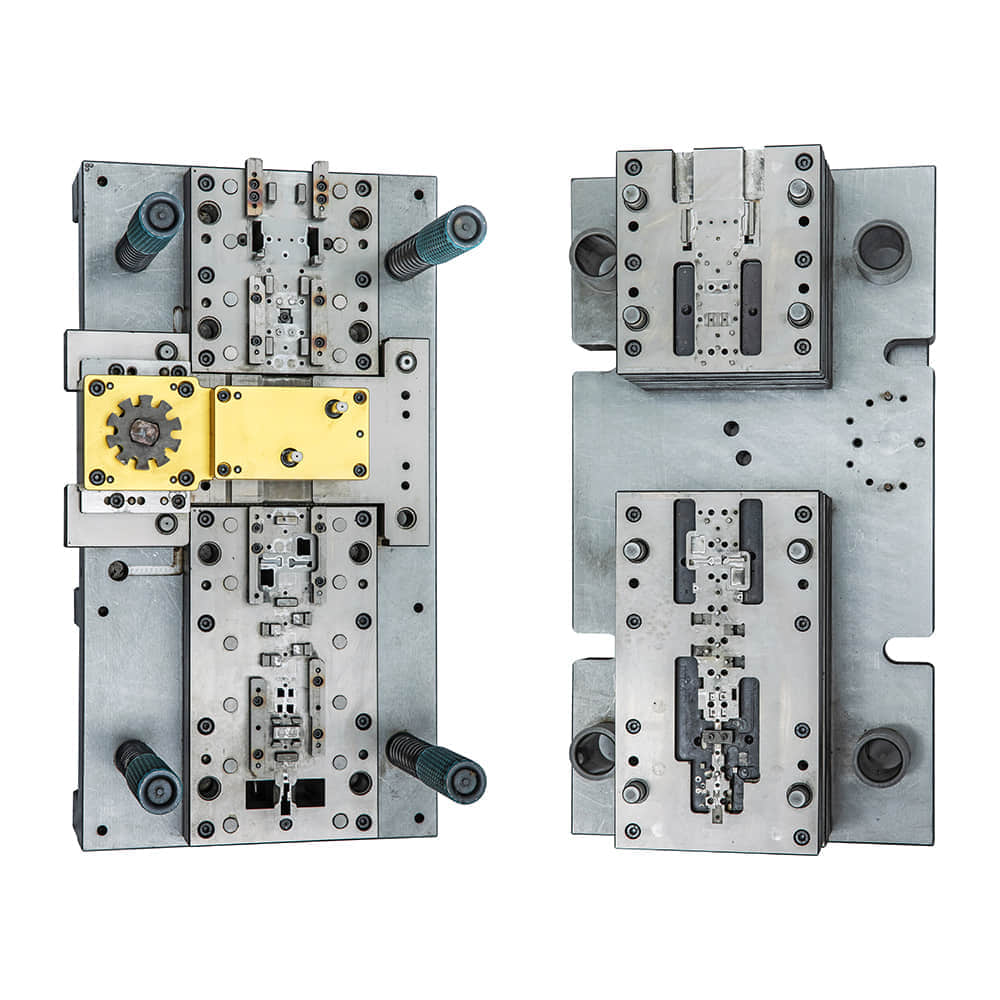

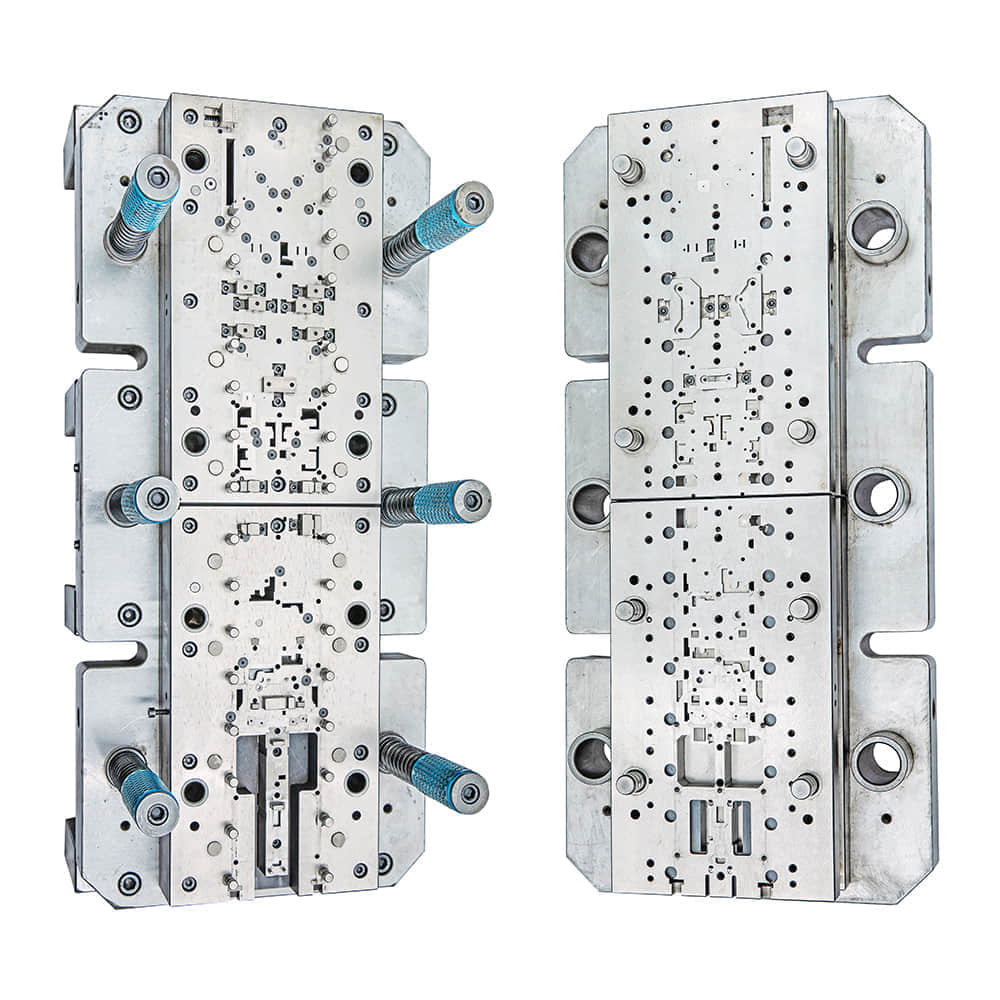

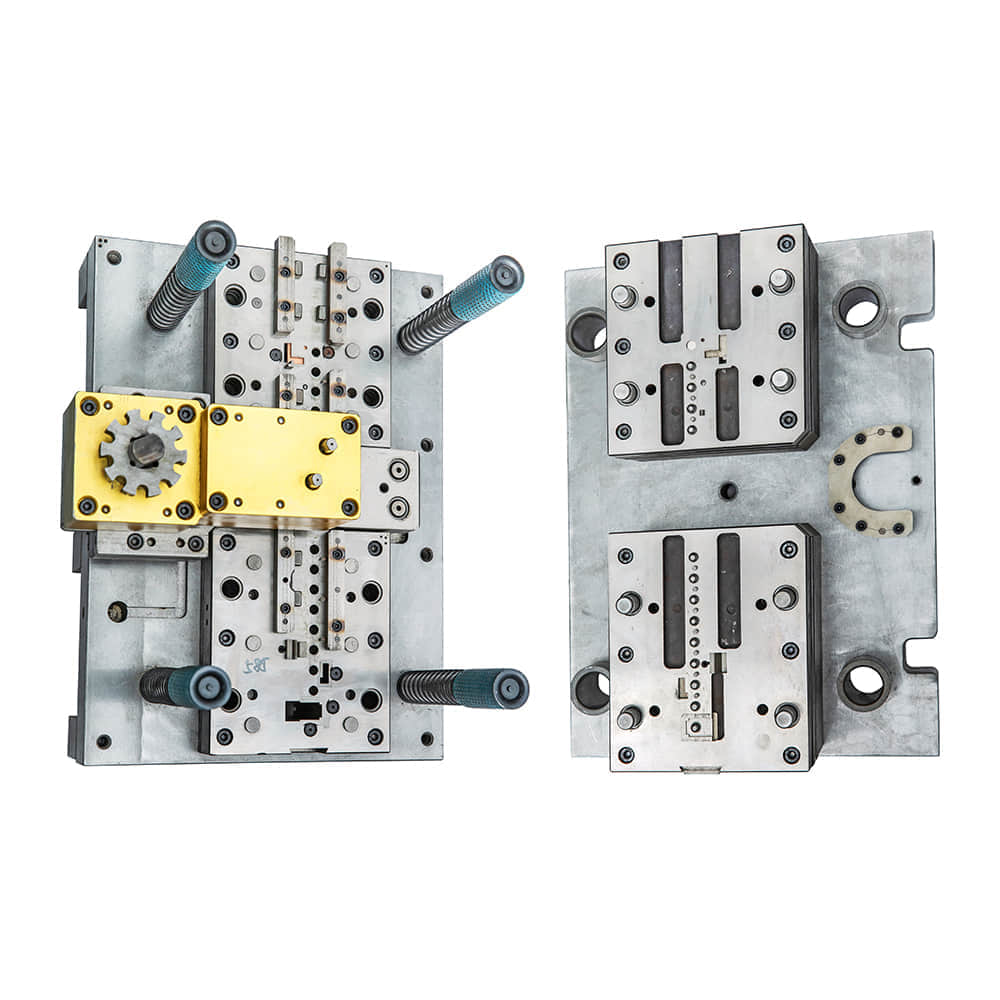

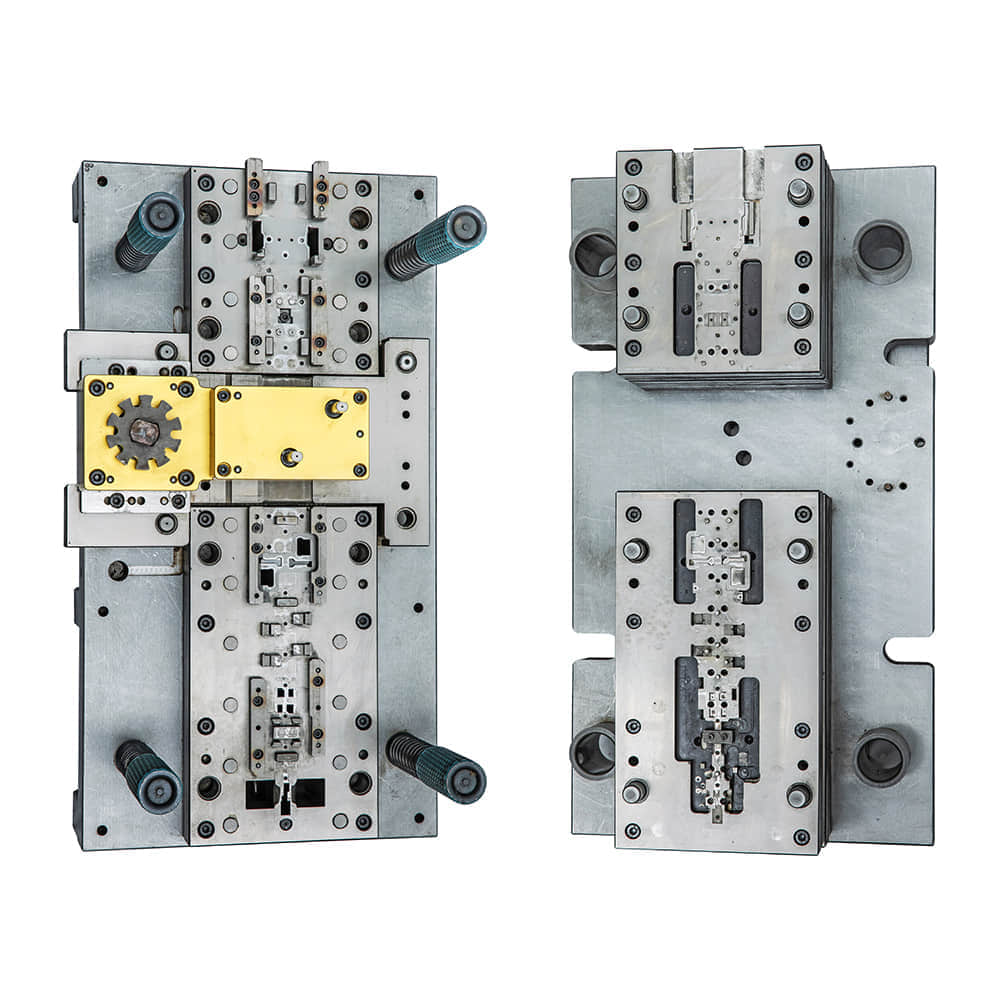

Metal stamping, often referred to as presswork, is a process where metal sheets are precisely shaped into desired forms using specialized machinery. The emergence of ODM manufacturers in this field stemmed from the need for customized, high-quality metal parts that meet stringent industry standards. These manufacturers, with their expertise and technological prowess, have filled the gap effectively. Customization at Its Best One of the standout attributes of Metal Stamping Parts ODM Manufacturers is their ability to offer tailor-made solutions. Every industry has unique requirements, and ODM manufacturers understand this. They work closely with their clients to design and produce metal parts that perfectly align with specific project needs. Whether it’s intricate automotive components or critical aerospace parts, customization is the hallmark of these ODM manufacturers. Cutting-Edge Technology Innovation is the lifeblood of Metal Stamping Parts ODM Manufacturers. They invest heavily in state-of-the-art technology, including computer-controlled stamping machines, laser cutting systems, and advanced quality control equipment. This commitment to technology ensures not only precision but also efficiency in production processes. Quality Assurance Quality control is non-negotiable in metal stamping. ODM manufacturers adhere to rigorous quality standards and have established robust quality assurance processes. From material selection to final inspection, each step is carefully monitored to deliver parts that meet or exceed industry benchmarks. This commitment to quality bolsters their reputation as reliable partners in the manufacturing ecosystem. Cost Efficiency and Scalability Metal Stamping Parts ODM Manufacturers excel in optimizing production costs. Through efficient material usage and streamlined processes, they offer cost-effective solutions without compromising on quality. Moreover, their ability to scale production up or down according to market demands makes them indispensable in industries characterized by fluctuations. Sustainability and Environmental Responsibility In today’s eco-conscious world, sustainable manufacturing practices are paramount. ODM manufacturers take their environmental responsibilities seriously. They implement eco-friendly materials and processes, ensuring minimal waste and reduced environmental impact. This dedication to sustainability aligns with the global trend toward greener manufacturing. Global Reach The impact of Metal Stamping Parts ODM Manufacturers extends far beyond their immediate geographical location. They often serve as vital links in global supply chains, exporting their products to clients worldwide. Their ability to navigate international regulations and standards makes them preferred partners for multinational corporations. Continuous Improvement The manufacturing landscape is in a constant state of flux, with new materials, techniques, and regulations emerging regularly. ODM manufacturers understand the importance of staying up-to-date. They invest in ongoing training for their workforce, keeping them informed about the latest industry trends and technologies. Conclusion Metal Stamping Parts ODM Manufacturers are the unsung heroes of modern manufacturing. Their ability to innovate, customize, ensure quality, and drive cost efficiency has revolutionized industries that rely on precision metal parts. As we move into an increasingly technologically advanced and environmentally conscious future, these manufacturers will continue to play a pivotal role in shaping the industrial landscape, one meticulously stamped part at a time.