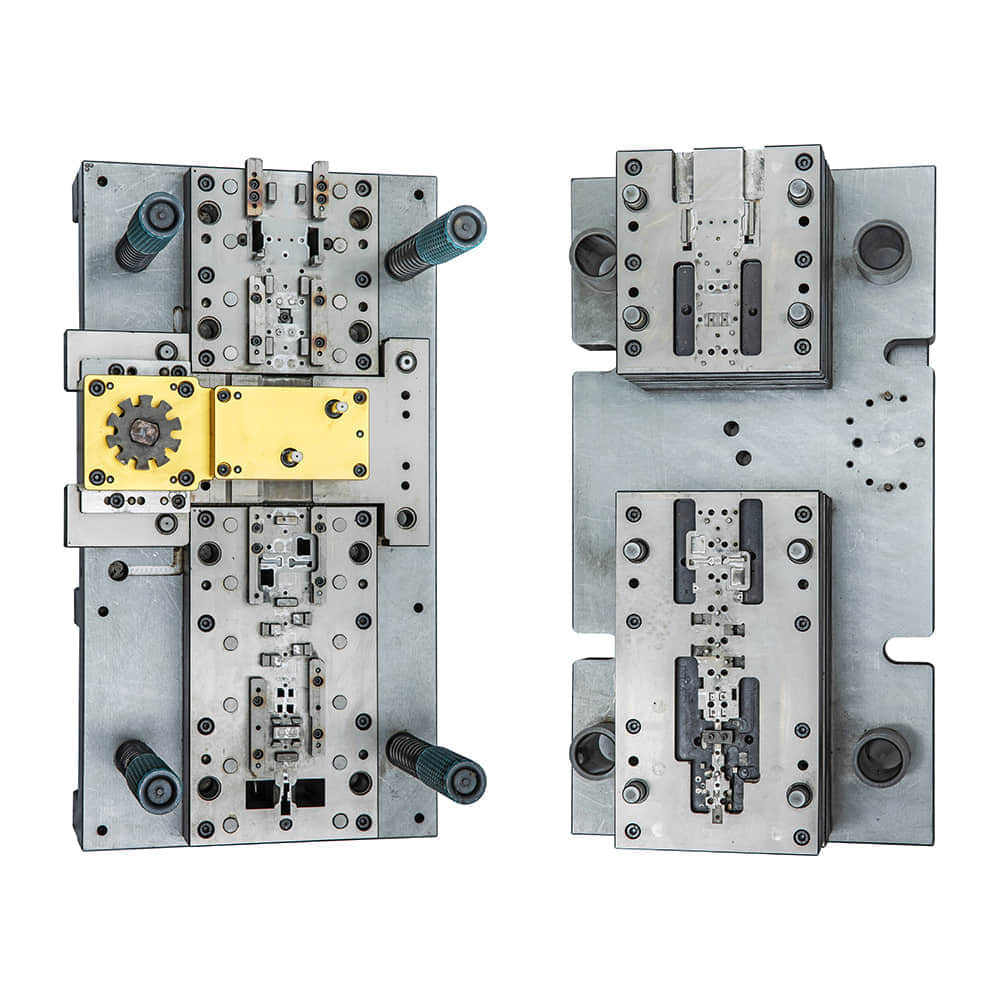

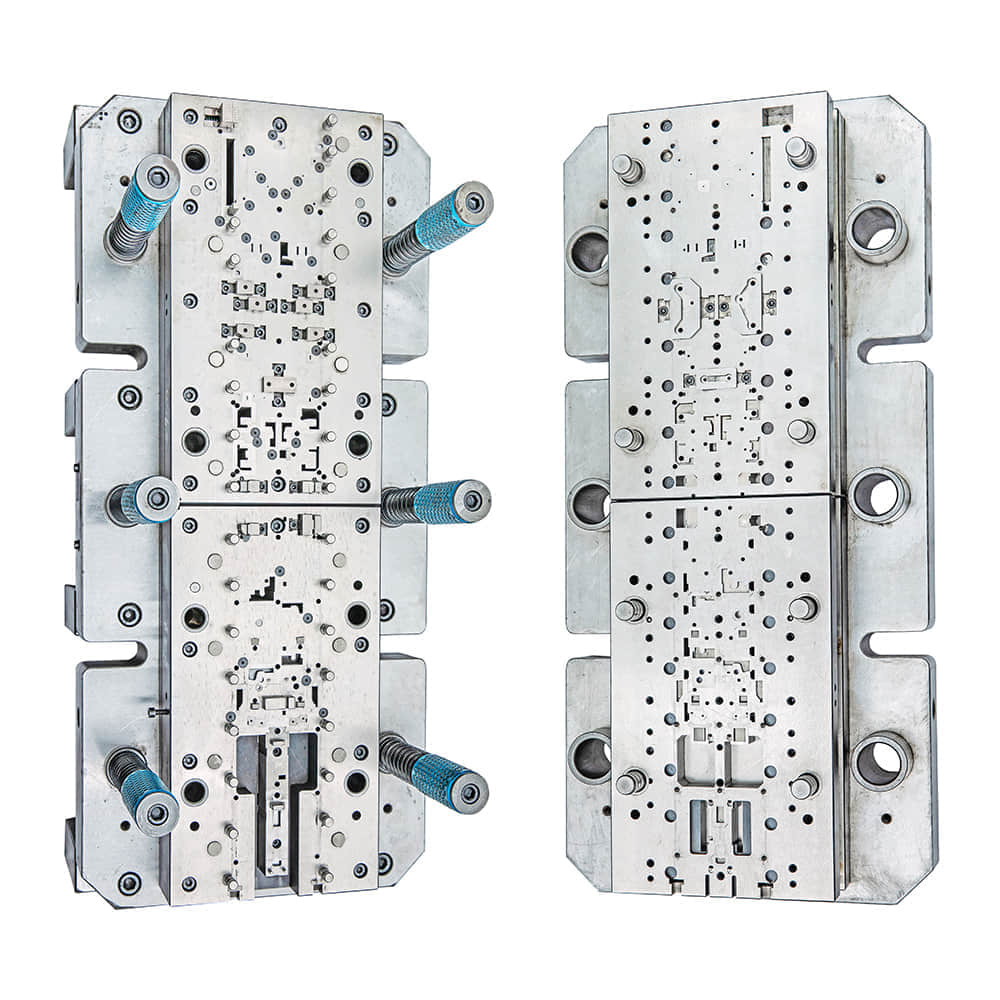

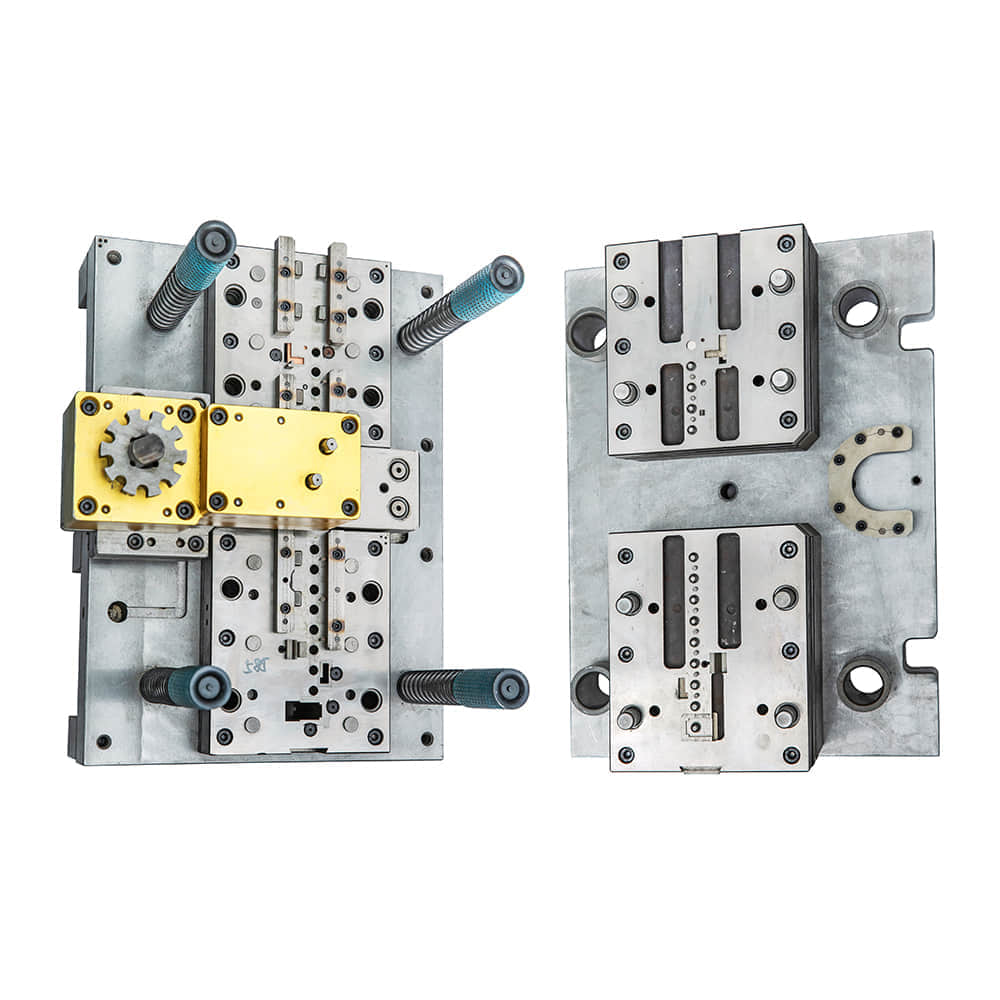

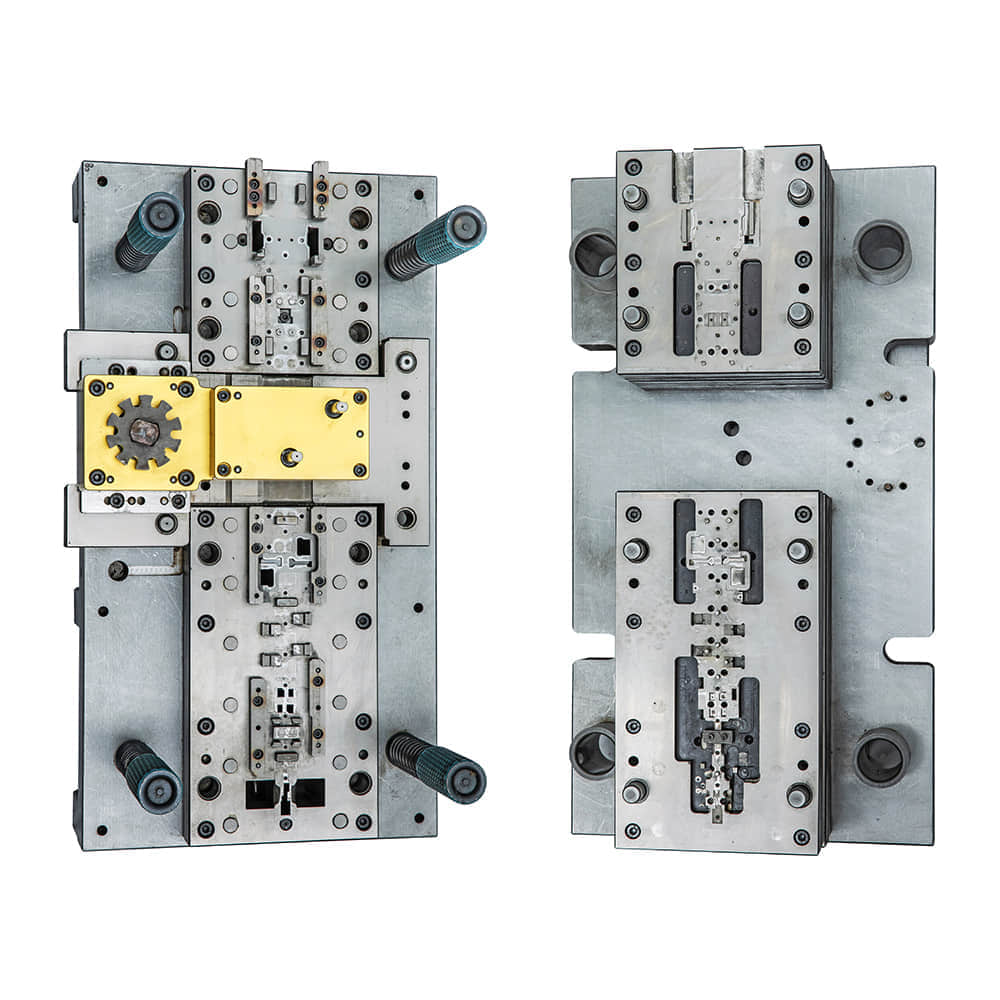

In the realm of manufacturing, precision and quality are paramount. Among the many sectors that rely on meticulous craftsmanship, metal stamping stands out as a foundational process. At the heart of this process lie metal stamping dies, intricate tools that shape raw metal into the desired forms. In recent years, China has emerged as a powerhouse in metal stamping die manufacturing, combining traditional expertise with cutting-edge technology to produce dies of unparalleled precision and quality.

A Legacy of Craftsmanship

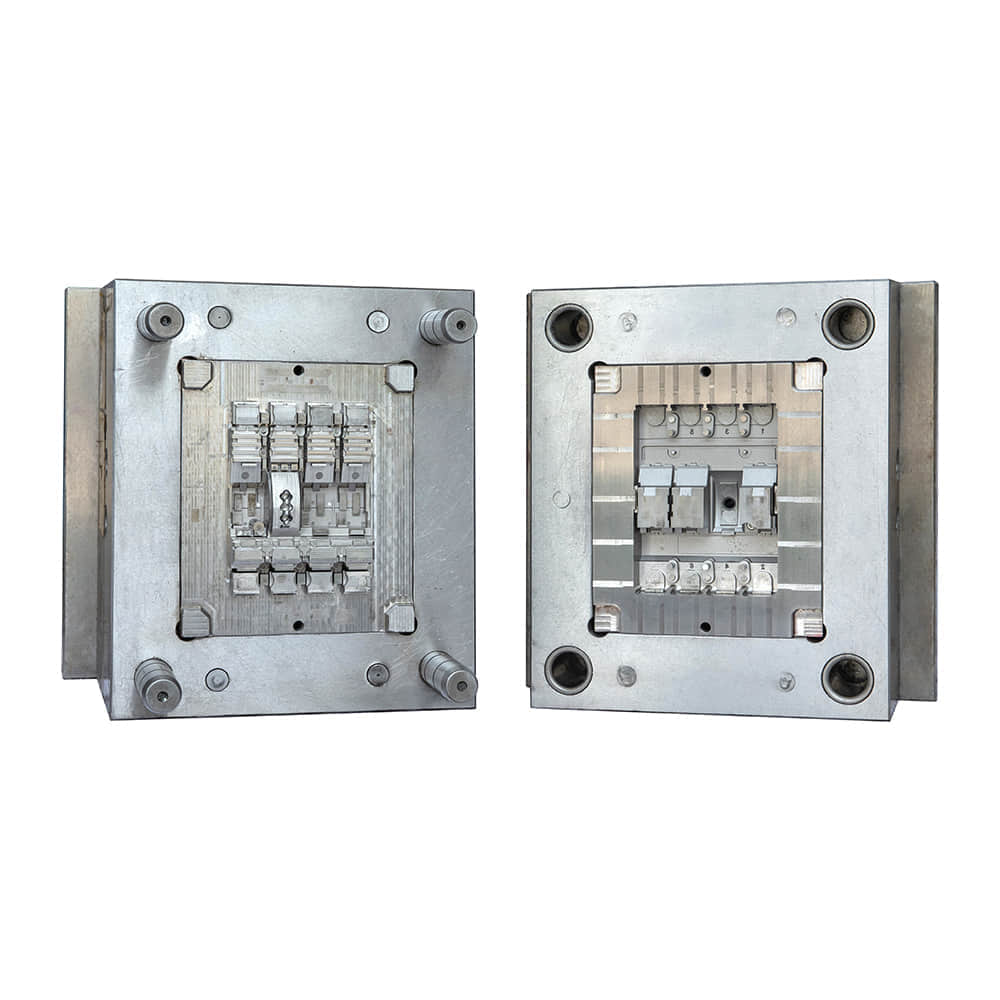

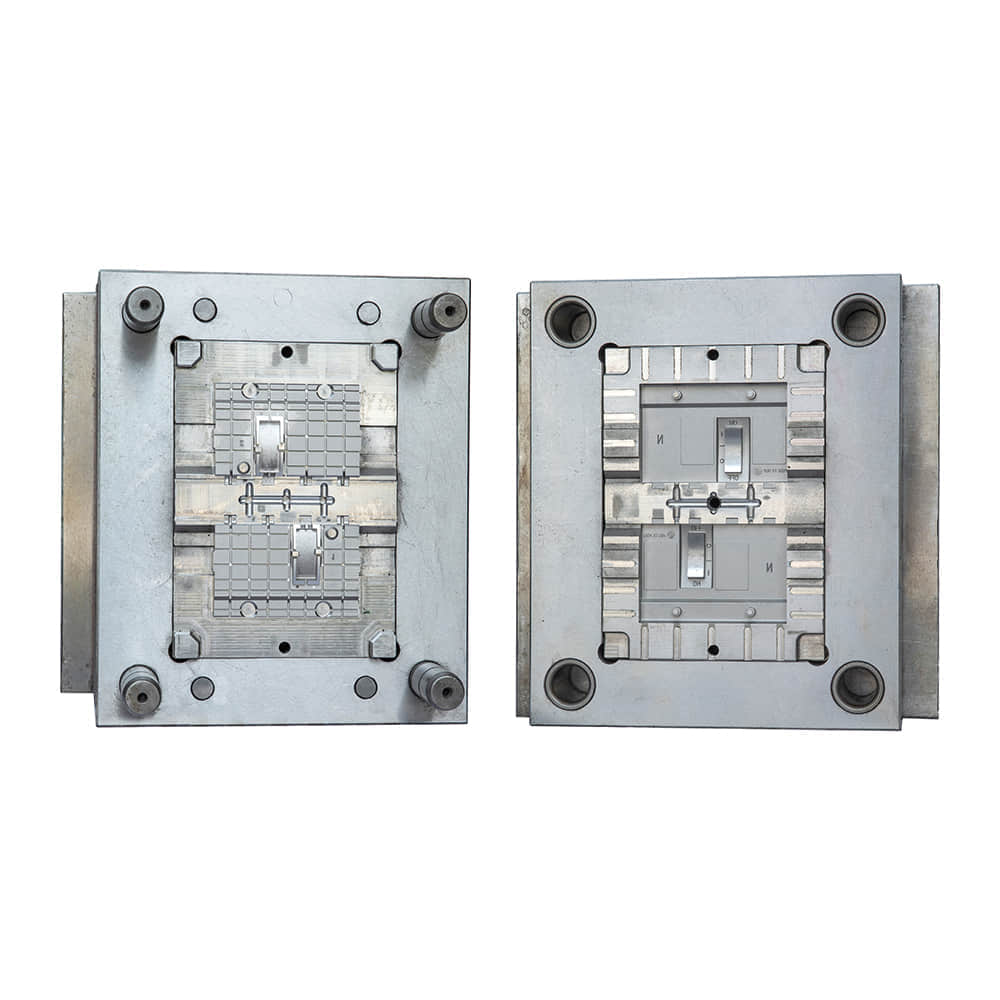

China’s history is rich with examples of skilled craftsmanship, and this legacy has extended to the realm of metalworking. The art of metal stamping, which involves pressing a metal sheet into a specific shape, has been practiced for centuries. From traditional copper coins to ornate metal artworks, Chinese artisans have honed their skills over generations. This foundation in craftsmanship has provided a solid base upon which modern metal stamping die manufacturers have built their expertise. Technological Leapfrogging In the modern era, China’s manufacturing industry has undergone a transformative technological leap. The country’s metal stamping die manufacturers have embraced automation, computer-aided design (CAD), and precision machining technologies. This integration of innovation has propelled China to the forefront of metal stamping die production. Today, Chinese manufacturers are sought after for their ability to create complex dies with tight tolerances, enabling the production of intricate metal components used in various industries, from automotive to electronics. Quality at the Core Quality control is a hallmark of China’s metal stamping die manufacturing sector. Recognizing the importance of precision in industries such as aerospace and medical equipment, manufacturers have implemented rigorous quality assurance processes. These include thorough inspections, advanced measuring techniques, and compliance with international standards. The dedication to maintaining high quality has earned China’s metal stamping die manufacturers a reputation for producing reliable and consistent results. Global Reach and Collaboration The globalization of supply chains has further elevated China’s role in metal stamping die manufacturing. Collaborations with international partners have led to the exchange of ideas and expertise, fostering continuous improvement. Chinese manufacturers have not only met the stringent demands of their domestic market but have also positioned themselves as key players in the global manufacturing landscape. Their ability to offer cost-effective solutions without compromising on quality has made them valuable partners for companies worldwide. Sustainability and Innovation China’s metal stamping die manufacturers are not only focused on excellence in production but also on sustainable practices. As environmental concerns rise, the industry has embraced eco-friendly materials and processes. From utilizing recyclable materials to implementing energy-efficient manufacturing methods, these manufacturers are driving innovation not only in precision engineering but also in responsible production. Looking Ahead As technology continues to advance and industries evolve, the role of metal stamping die manufacturers remains pivotal. China’s unique combination of traditional craftsmanship and technological prowess has positioned it as a global leader in this field. With a commitment to quality, innovation, and collaboration, China’s metal stamping die manufacturers are poised to shape the future of manufacturing, one precise cut at a time. In conclusion, China’s metal stamping die manufacturers have seamlessly blended a rich history of craftsmanship with cutting-edge technology to become trailblazers in the industry. Their precision, quality, and commitment to advancement have solidified their place on the global stage, driving innovation and shaping diverse sectors that rely on their expertise.