In the world of electrical engineering, safety and reliability are paramount. One critical component that plays a pivotal role in ensuring the safety and functionality of electrical systems is the frame circuit breaker withdrawal switch. This article sheds light on the significance of frame circuit breaker withdrawal switches and introduces a leading manufacturer in this field.

The Role of Frame Circuit Breaker Withdrawal Switches

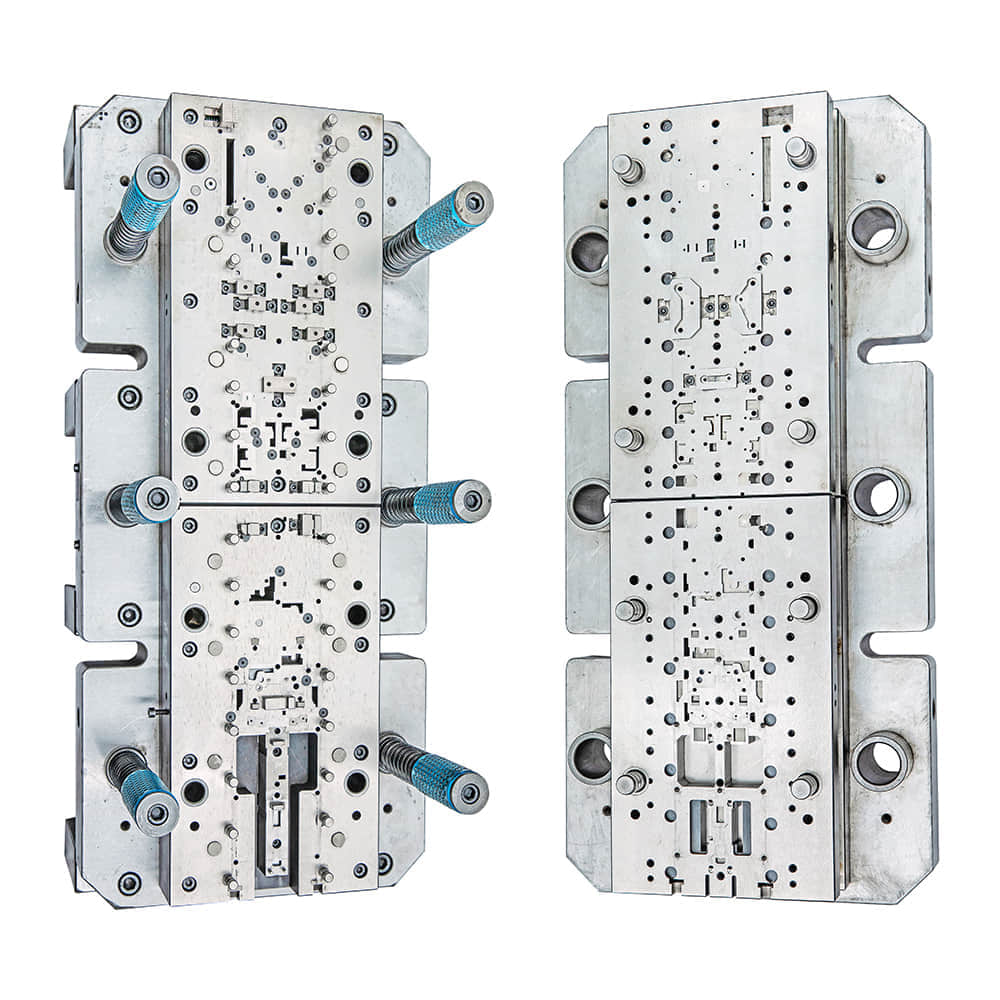

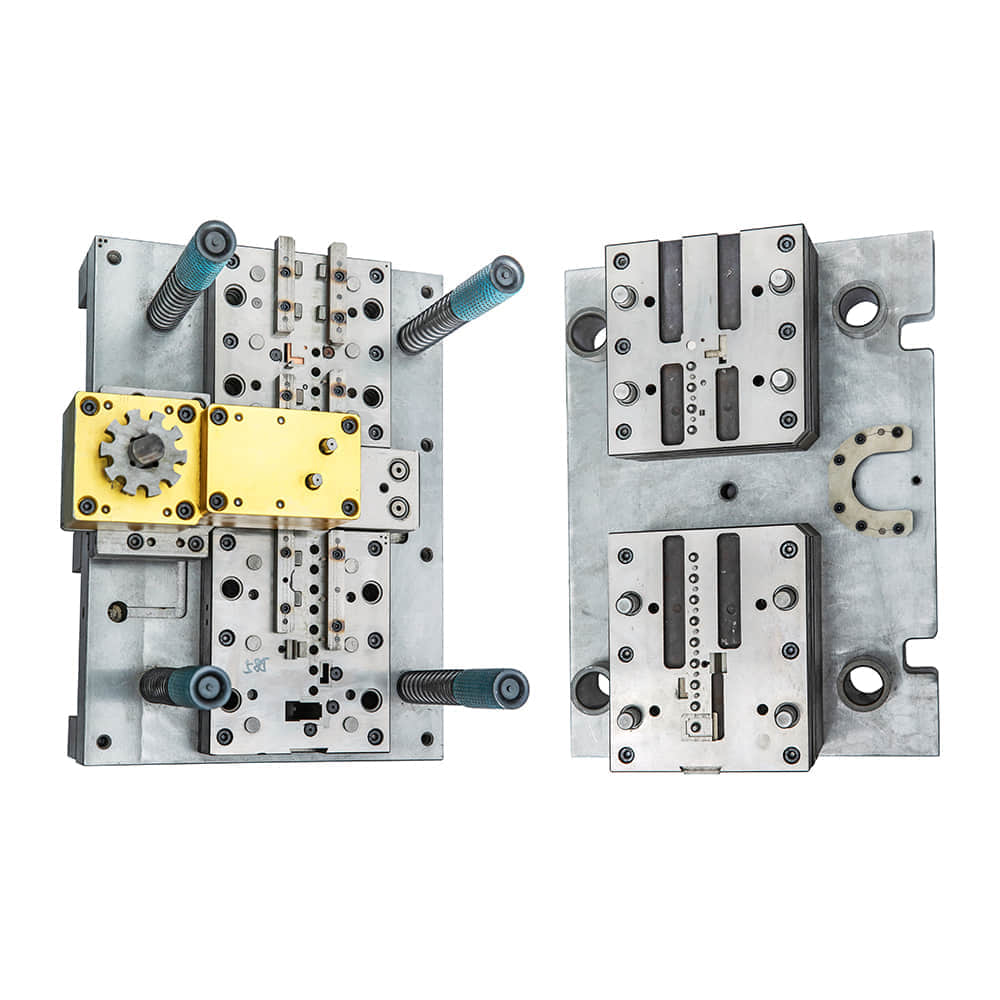

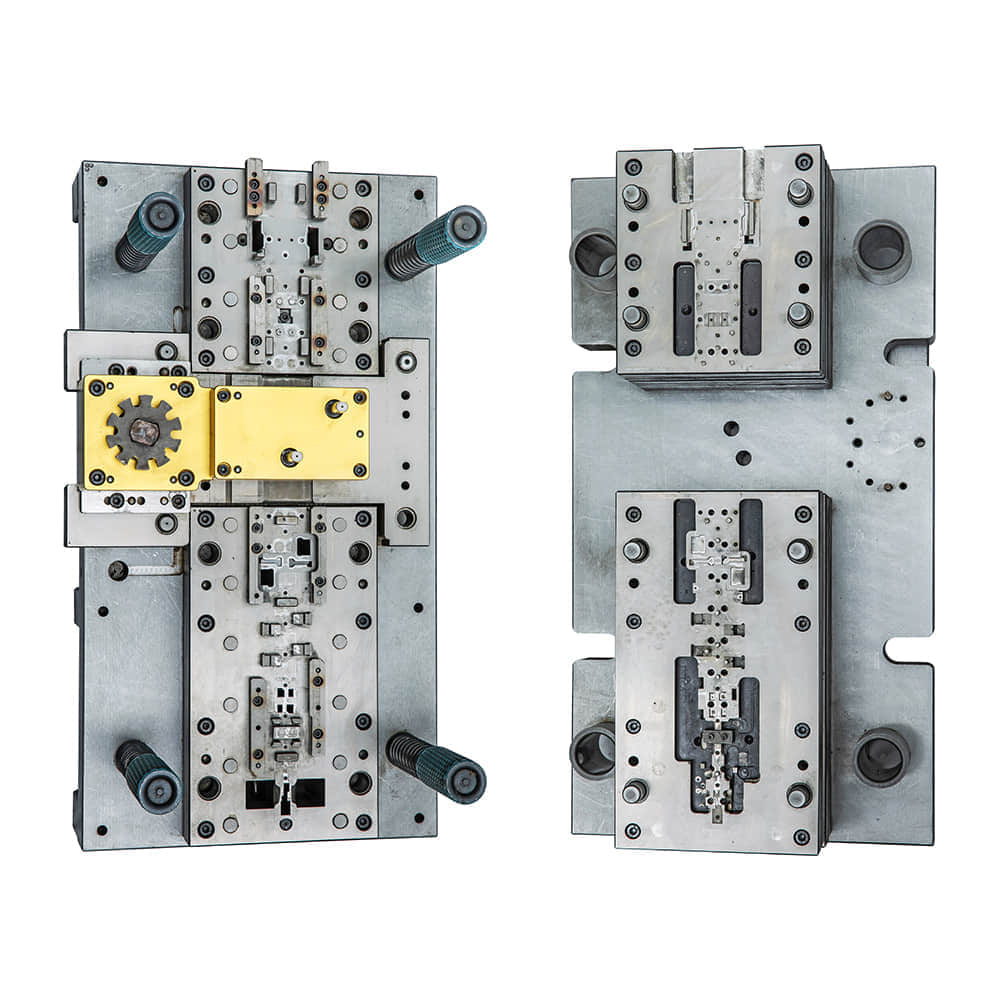

Frame circuit breaker withdrawal switches are fundamental components within electrical distribution systems. These switches facilitate the safe and efficient operation of circuit breakers, enabling electrical engineers and technicians to isolate circuits, perform maintenance, and replace circuit breakers when necessary. They serve as a crucial interface between the circuit breaker and the electrical distribution panel. The primary functions of frame circuit breaker withdrawal switches include: Isolation:These switches allow for the complete isolation of the circuit breaker from the power source, ensuring that electrical work can be conducted safely without the risk of electrical shocks or accidents. Maintenance:Frame circuit breaker withdrawal switches enable the removal of circuit breakers for routine inspections, repairs, or replacements. This feature is vital for the reliability and longevity of electrical systems. Safety:By providing a physical barrier between the circuit breaker and the operator, these switches enhance safety during maintenance procedures. They prevent accidental engagement of the circuit breaker during maintenance. Versatility:Frame circuit breaker withdrawal switches are designed to accommodate various types and sizes of circuit breakers, making them a versatile solution for different applications. Introducing a Leading Manufacturer When it comes to frame circuit breaker withdrawal switches, one manufacturer stands out for its commitment to quality, innovation, and customer satisfaction: [Manufacturer Name]. With a history spanning over [number] years in the industry, they have earned a reputation as a trusted and reliable supplier of electrical components. Here are some key attributes that set [Manufacturer Name] apart from the competition: Quality Assurance:[Manufacturer Name] places a strong emphasis on quality control and assurance. Their products undergo rigorous testing to meet and exceed industry standards, ensuring reliability and safety in every application. Innovation:The company continuously invests in research and development to stay at the forefront of technological advancements. This commitment to innovation results in products that are not only reliable but also feature-rich, meeting the evolving needs of the electrical industry. Customization:[Manufacturer Name] understands that each electrical system is unique. They offer a range of customization options to tailor frame circuit breaker withdrawal switches to the specific requirements of their customers. Customer Support:Providing exceptional customer support is a core value for [Manufacturer Name]. Their team of experts is readily available to assist with product selection, technical inquiries, and after-sales service. Global Presence:With a global distribution network, [Manufacturer Name] serves customers around the world, ensuring that their high-quality products are accessible to a diverse range of industries and applications. Conclusion Frame circuit breaker withdrawal switches are indispensable components in the world of electrical engineering, ensuring the safety, reliability, and maintenance of electrical systems. When seeking a manufacturer for these critical components, [Manufacturer Name] stands as a trusted choice, backed by years of industry experience, a commitment to quality, and a dedication to customer satisfaction. Whether you are designing a new electrical system or upgrading an existing one, [Manufacturer Name] is your partner in ensuring the utmost safety and efficiency.