In the world of manufacturing, precision and efficiency are paramount. One industry that plays a crucial role in achieving these goals is metal stamping die OEM manufacturing. These manufacturers are the unsung heroes behind the scenes, creating the tools that shape and mold metal into intricate components used in various industries. In this article, we will delve into the world of metal stamping die OEM manufacturers, exploring their significance, processes, and the impact they have on our daily lives.

The Significance of Metal Stamping Die OEM Manufacturers

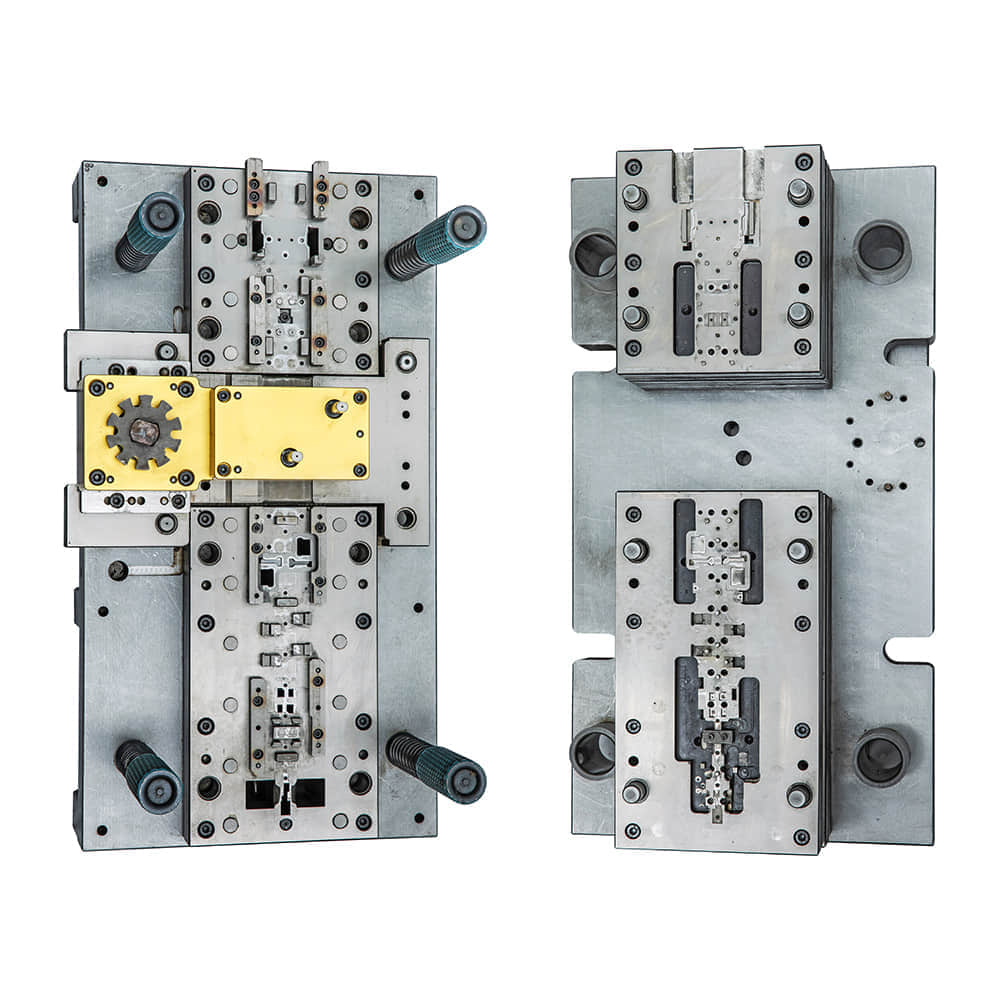

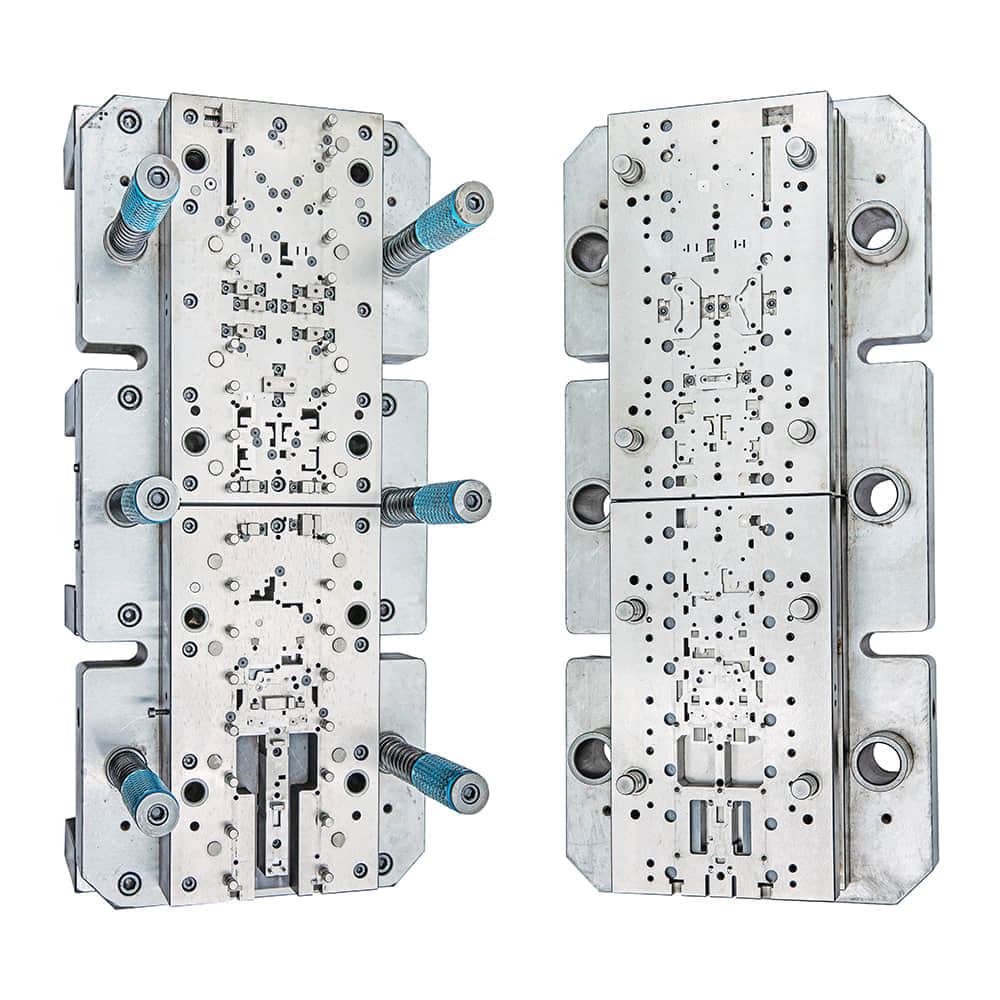

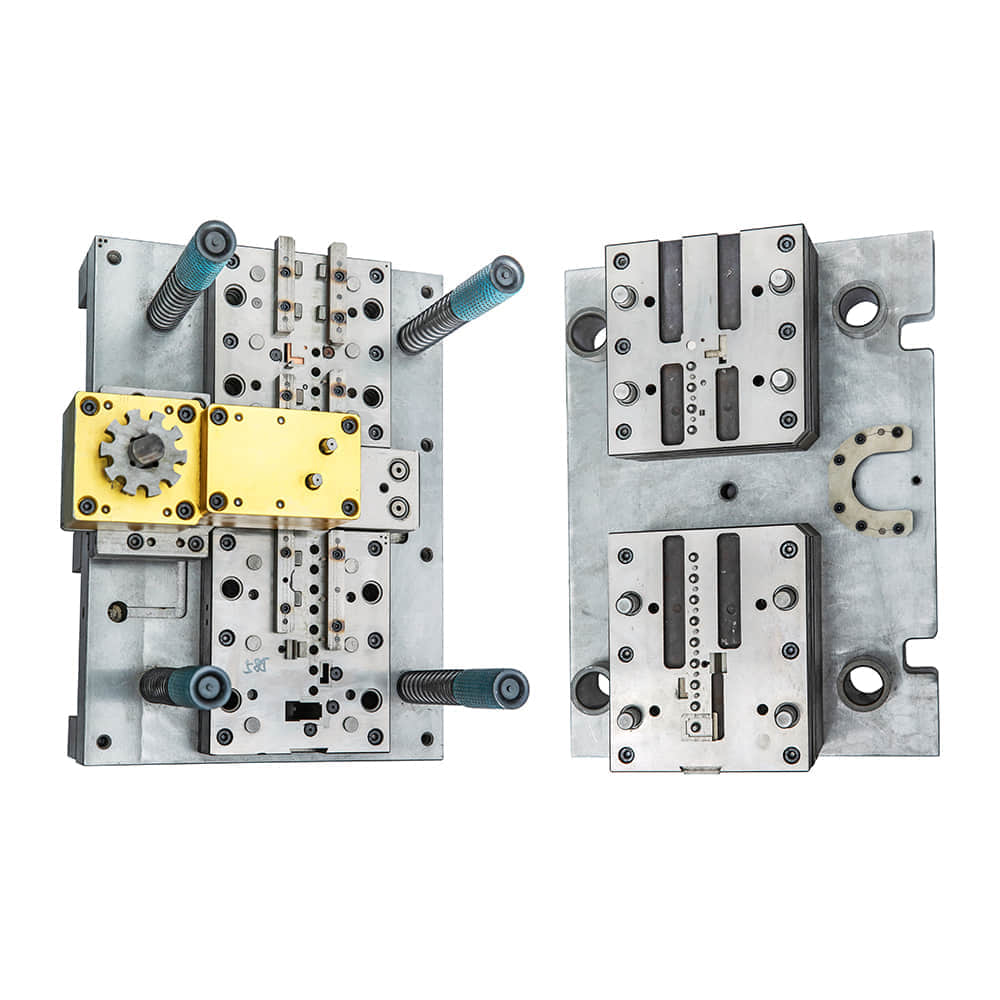

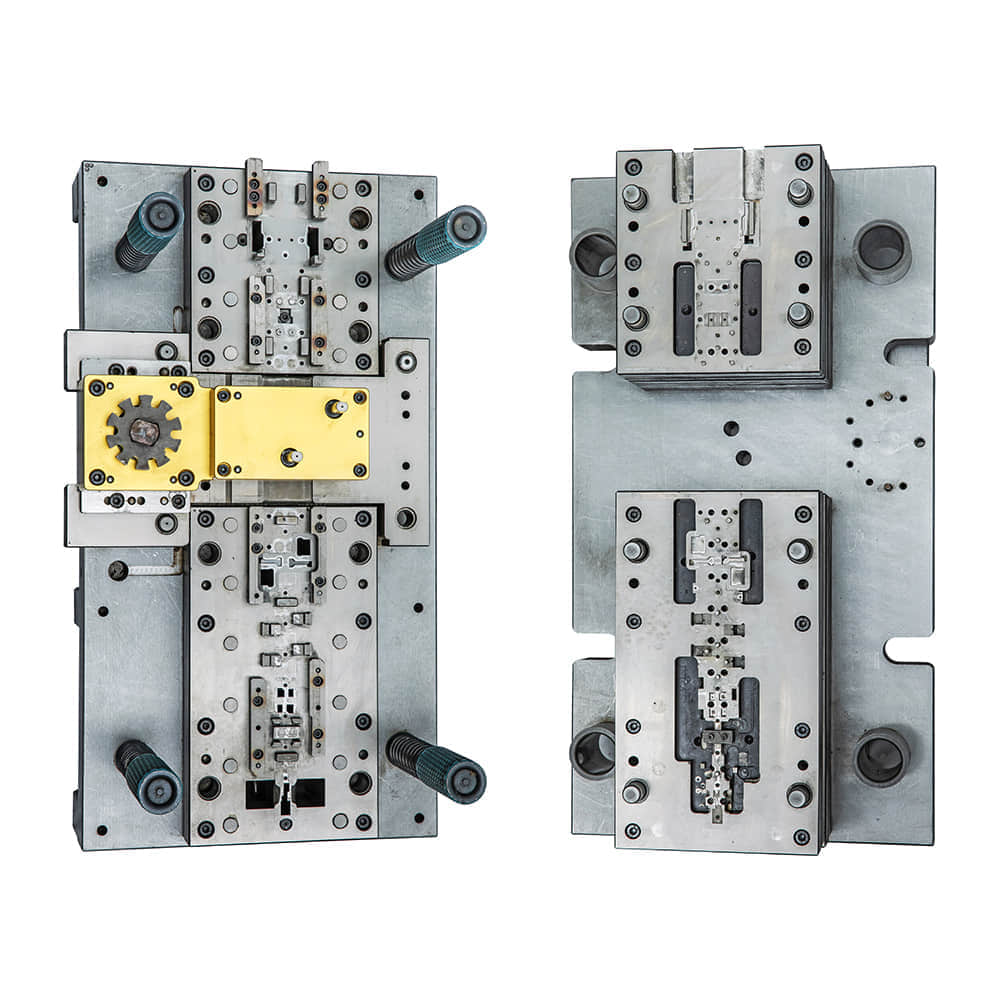

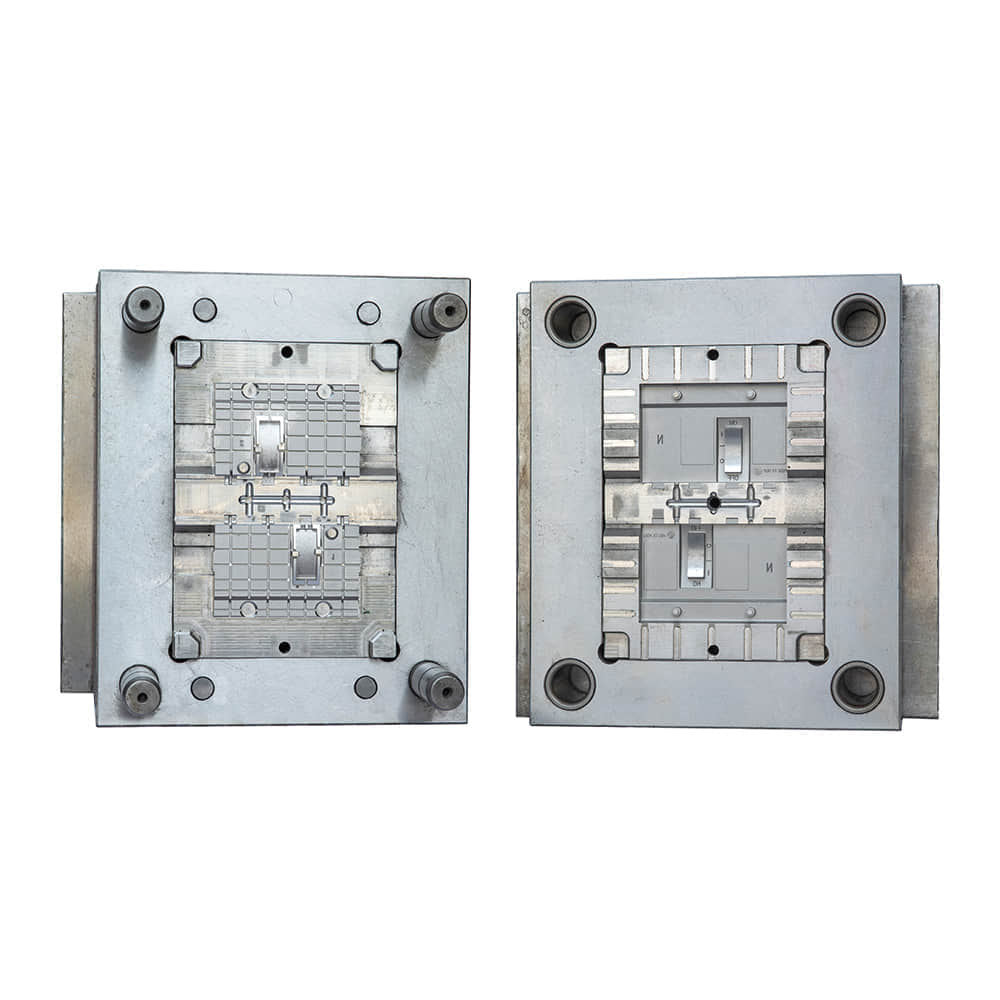

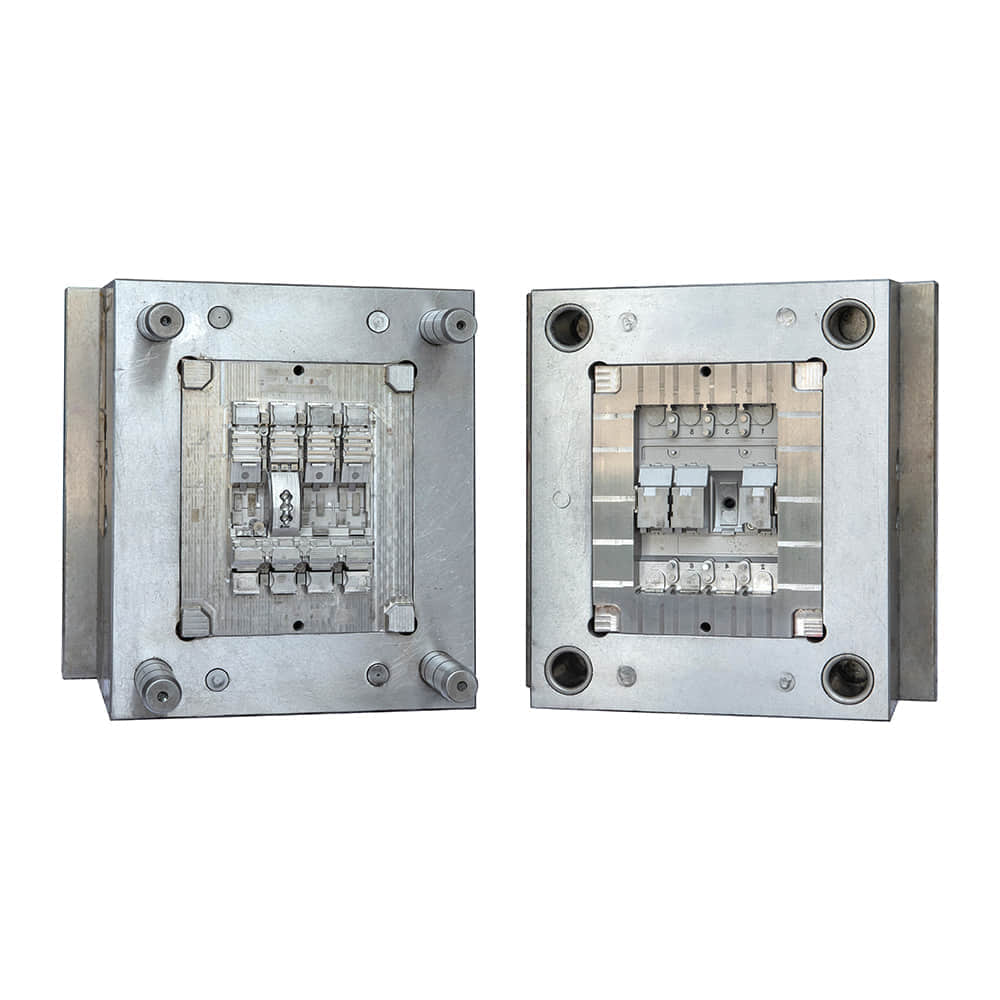

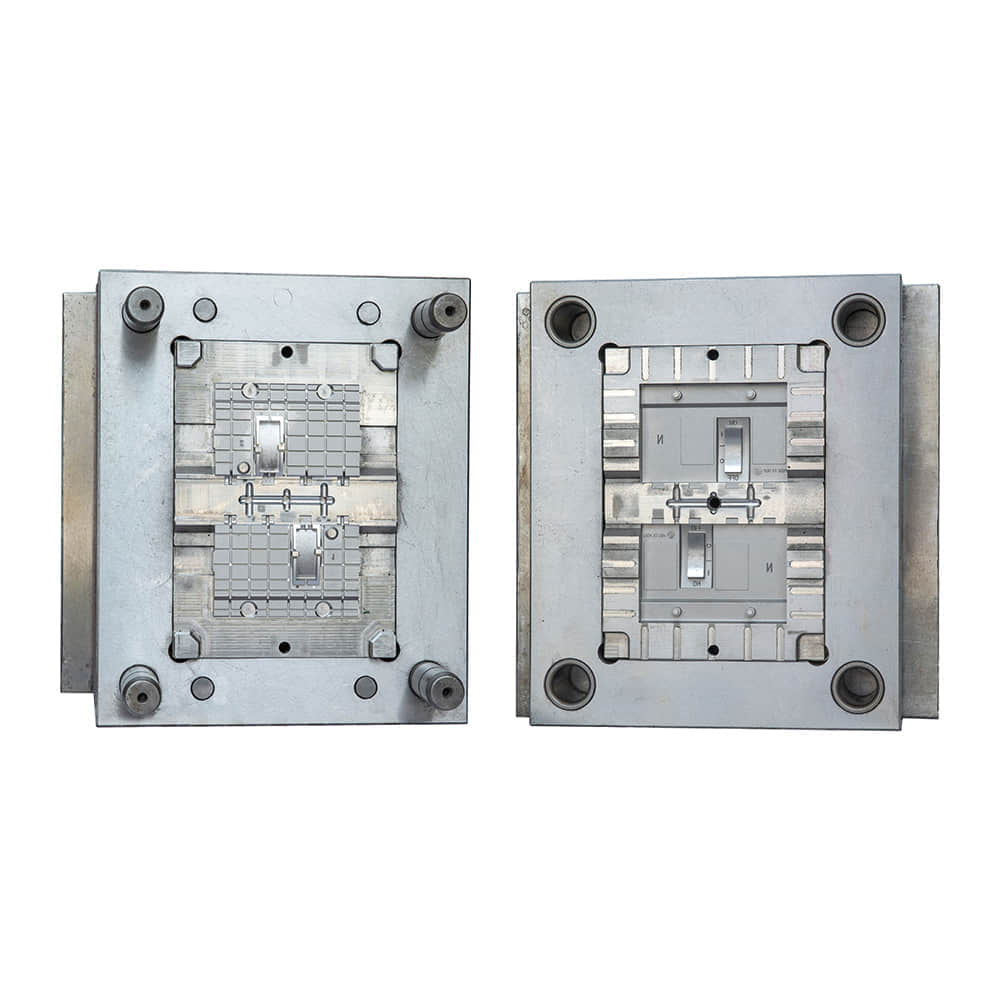

Metal stamping die OEM manufacturers are the driving force behind the production of many everyday items, from automobile parts to household appliances. Their expertise lies in crafting dies – specialized tools used in the metal stamping process. These dies are designed to cut, bend, shape, and form metal sheets into precise components with minimal waste. As a result, manufacturers can produce parts with consistent quality and high accuracy. Precision Engineering and Innovation Precision is the hallmark of metal stamping die OEM manufacturers. These professionals blend traditional craftsmanship with modern technology to create dies that meet stringent tolerances. Computer-aided design (CAD) software allows them to visualize intricate designs before they are manufactured. This precision not only ensures the desired outcome but also reduces material wastage and production time. Innovation is also a driving force in this industry. As new materials and manufacturing techniques emerge, metal stamping die OEM manufacturers must adapt and innovate to remain competitive. They continually push the boundaries of what is possible, developing dies that can work with exotic materials, produce complex shapes, and achieve incredibly tight tolerances. The Manufacturing Process The journey of a metal stamping die from concept to production is a meticulous one. It starts with collaboration between engineers, designers, and clients to understand the requirements of the component to be manufactured. Once the design is finalized, the manufacturing process begins. The first step is material selection. The choice of material depends on factors such as the type of metal being stamped, the desired part’s complexity, and the expected production volume. Next comes the design and engineering of the die itself, which involves intricate planning of how the metal will be formed, cut, and shaped. Manufacturing the die involves a mix of traditional craftsmanship and advanced machinery. Skilled toolmakers use cutting-edge CNC (Computer Numerical Control) machines to shape and precision-grind the components of the die. These components must fit together seamlessly to ensure the final product’s accuracy. After the die is manufactured, it undergoes testing and refinement. This iterative process ensures that the die produces the desired components with high precision and consistency. Once approved, the die is ready for mass production, enabling the creation of countless identical parts. Impact on Industries and Daily Life The work of metal stamping die OEM manufacturers reverberates through numerous industries. The automotive sector relies on them for producing engine parts, chassis components, and intricate electronic connections. The aerospace industry benefits from their ability to manufacture lightweight yet strong parts. Even the electronics sector depends on metal stamping dies to create intricate components for devices we use daily. In our daily lives, metal stamping die OEM manufacturers play a role that often goes unnoticed. The appliances we use, the vehicles we drive, and the gadgets we rely on all incorporate components made possible by their expertise. Without their precise work, modern life as we know it would be vastly different. Conclusion Metal stamping die OEM manufacturers are the unsung champions of precision engineering. Their intricate work shapes the world around us, enabling industries to produce high-quality components with efficiency and accuracy. From concept to production, these manufacturers blend craftsmanship with innovation to create dies that drive progress and innovation in various sectors. As we continue to advance technologically, their role will remain pivotal in shaping the future of manufacturing.