In the realm of electrical engineering, the term “ACB” holds significant importance. ACB stands for Air Circuit Breaker, a crucial component that ensures the safety and stability of electrical systems. As the global demand for electricity continues to rise, China has emerged as a powerhouse in ACB manufacturing, combining precision and innovation to provide solutions that power the world.

Precision Engineering: Setting the Foundation

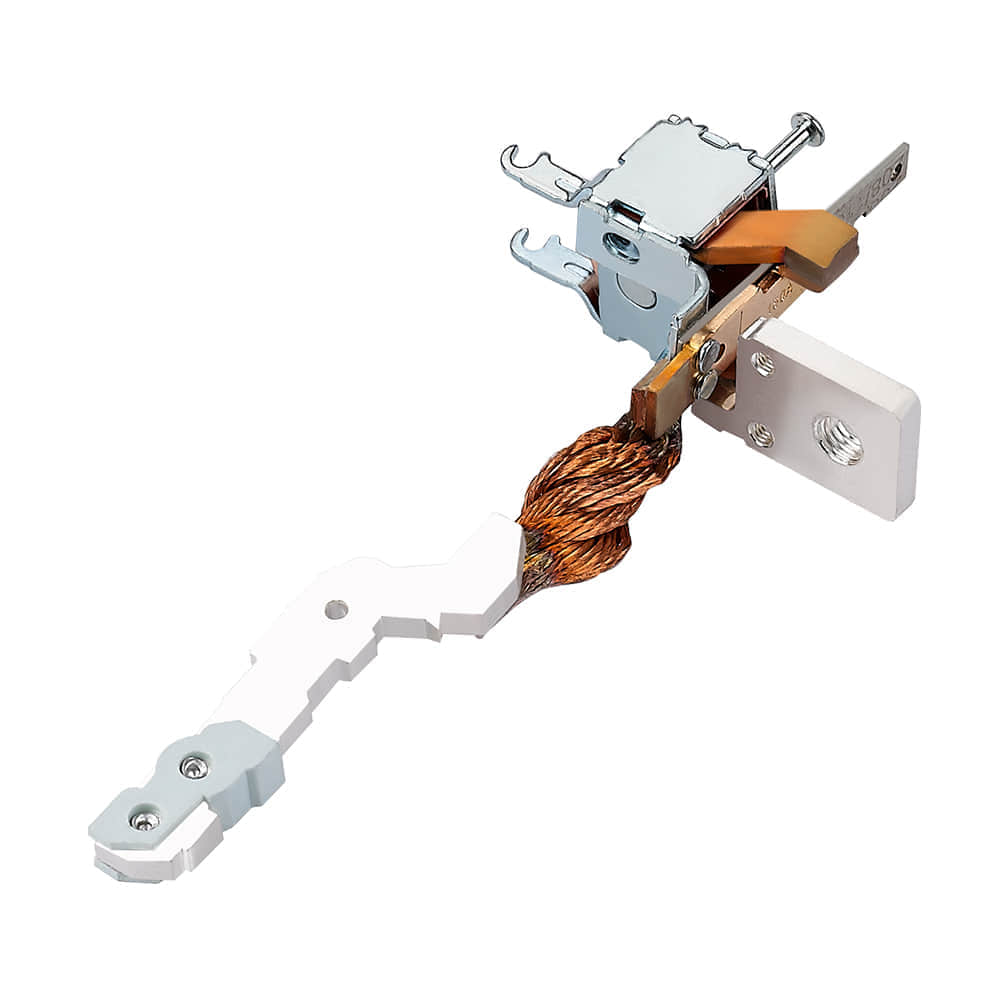

China’s ACB manufacturing industry is built upon a foundation of precision engineering. ACBs are designed to interrupt currents in the event of a fault, preventing potential damage to equipment and infrastructure. The precision required in manufacturing ACBs is immense, as even the slightest deviation can impact their performance. Chinese manufacturers have invested heavily in advanced production techniques and state-of-the-art machinery to achieve the required precision. From the selection of high-quality materials to the intricacies of circuitry and mechanism design, every step is executed with meticulous attention to detail. This commitment to precision ensures that China-produced ACBs can handle varying electrical loads while maintaining reliability, making them an essential component in industries ranging from manufacturing to energy distribution. Innovation at the Core Innovation is the driving force that propels China’s ACB manufacturing industry forward. As technology evolves, so do the demands on electrical systems. ACBs must adapt to new challenges, such as increased energy consumption, renewable energy integration, and smart grid capabilities. Chinese manufacturers have embraced these challenges as opportunities to innovate. One notable innovation is the integration of digital intelligence into ACBs. Smart ACBs can communicate real-time data about electrical currents, temperatures, and operational status. This information enables predictive maintenance, reducing downtime and optimizing system performance. Additionally, smart ACBs can be remotely controlled, enhancing their applicability in complex industrial settings. Furthermore, China’s ACB manufacturers are at the forefront of sustainability. With a global emphasis on reducing carbon footprints, ACBs are being designed to be more energy-efficient. These energy-efficient ACBs not only contribute to a greener environment but also result in long-term cost savings for users. Global Impact and Reach China’s prowess in ACB manufacturing has extended its reach beyond its borders. Chinese ACBs are not only meeting domestic demands but are also being exported to countries around the world. The reliability, precision, and innovation showcased in these products have gained international recognition. In regions where reliable power distribution is crucial, such as data centers, manufacturing facilities, and critical infrastructure installations, China’s ACBs have found a significant market. The ability to seamlessly handle high electrical loads and the integration of intelligent features make them an asset in various sectors. Challenges and Future Prospects While China’s ACB manufacturing industry has achieved remarkable success, it’s not without its challenges. The industry must continuously adapt to evolving technological standards, safety regulations, and customer demands. Competition is fierce, and maintaining an edge requires relentless innovation and dedication to quality. Looking ahead, the future prospects for China’s ACB manufacturing industry remain promising. As the global demand for electricity continues to rise and industries become increasingly reliant on advanced electrical systems, ACBs will remain a critical component. China’s commitment to precision engineering, innovation, and adaptability positions it well to continue making a significant impact on the ACB market. Conclusion In the realm of electrical engineering, ACBs stand as guardians of power systems, ensuring their safe and efficient operation. China’s ACB manufacturing industry has risen to the occasion, combining precision engineering with innovative solutions that meet the demands of a rapidly evolving technological landscape. With a global reach and a focus on sustainability, China’s ACBs are driving the world’s industries toward a future powered by reliability and efficiency.