Thermosetting compression moulding is a pivotal technique in the realm of manufacturing, offering a diverse range of applications across industries. This method involves the shaping and forming of thermosetting materials, making them indispensable in the creation of a myriad of products. In this article, we delve into the intricacies of thermosetting compression moulding, its process, and its significance in modern production processes.

Understanding Thermosetting Compression Moulding

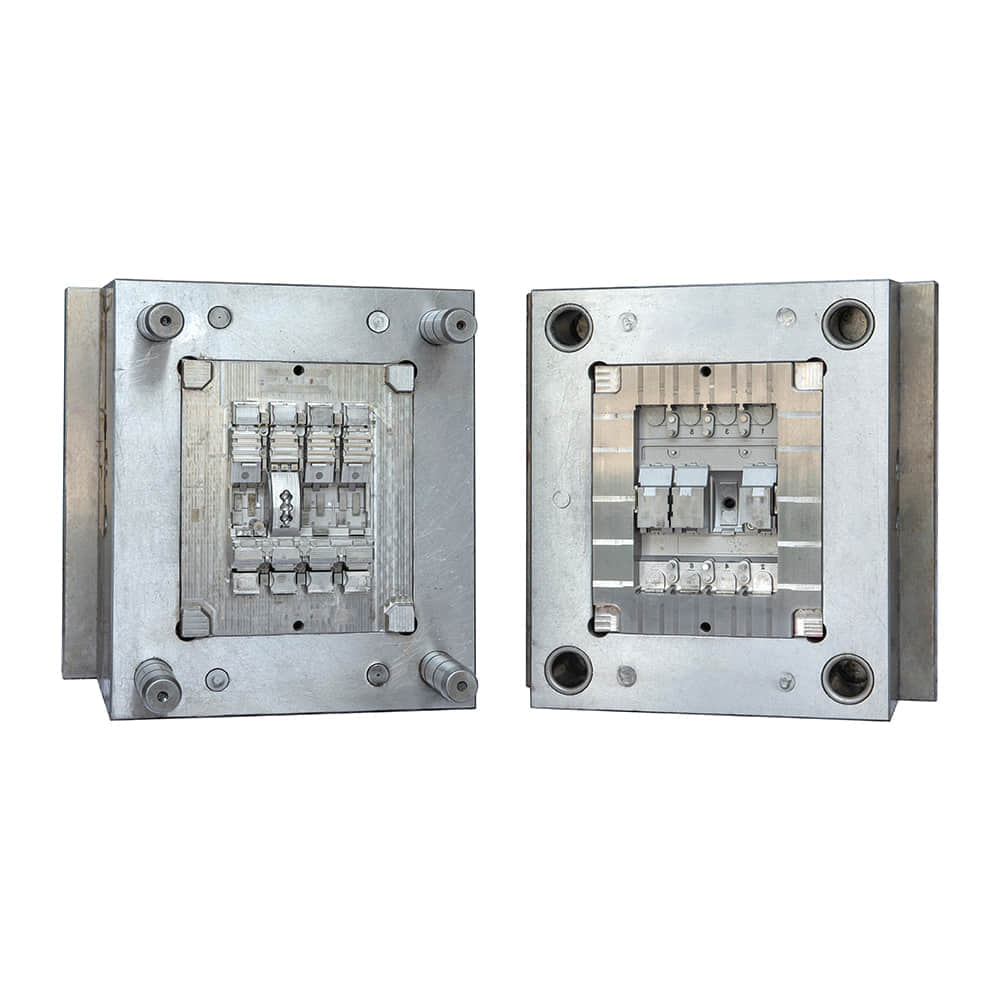

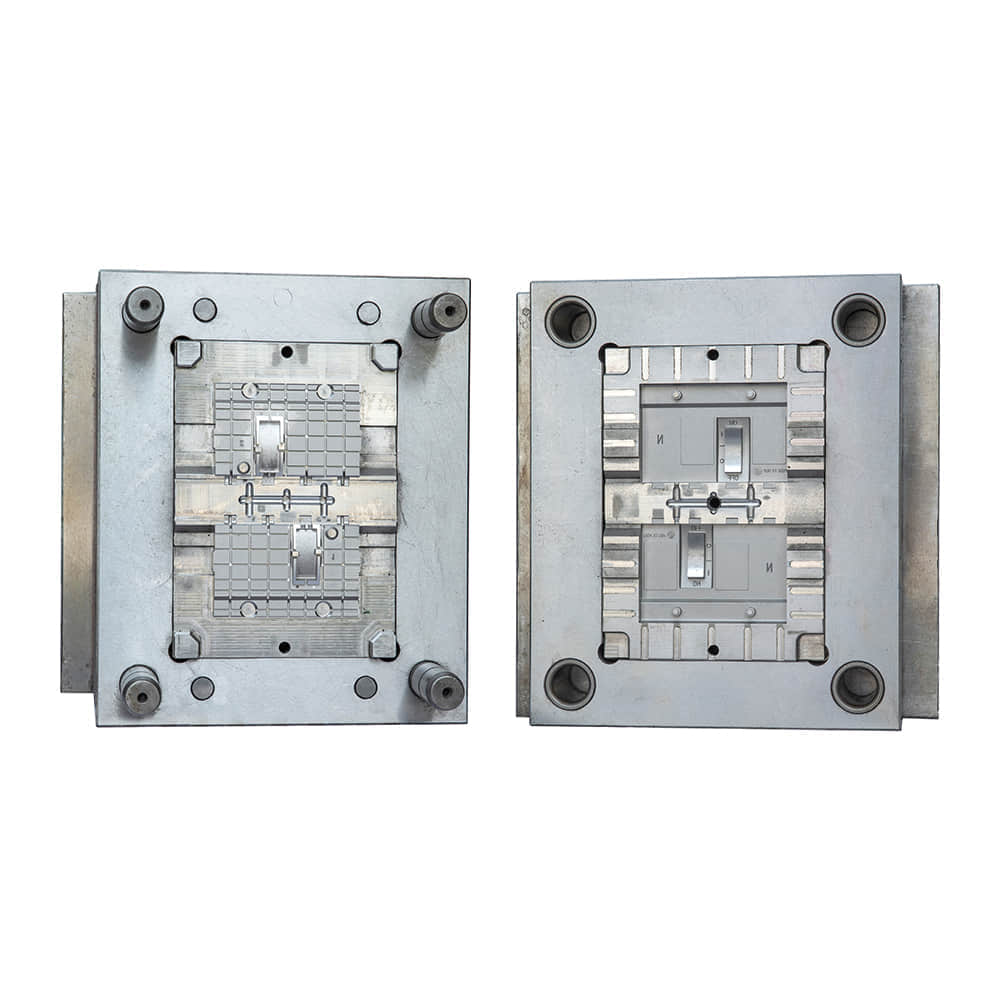

Thermosetting materials are polymers that, once cured, become rigid and infusible. Unlike thermoplastics, these materials undergo a chemical reaction during the curing process that irreversibly solidifies their structure. Thermosetting compression moulding capitalizes on this unique property, allowing for the creation of products that need to withstand high temperatures and exhibit exceptional strength and durability. The Process The process of thermosetting compression moulding involves several key steps: 1. Material Preparation:The first step is to prepare the thermosetting material. This typically involves mixing the base resin with other additives, such as curing agents, fillers, and reinforcing materials like fibers. This mixture is often in the form of granules, pellets, or powders. 2. Loading the Mould:The prepared material is placed into a preheated mould cavity. The mould is typically made from metal and consists of two halves that fit together precisely. It is designed according to the desired shape and dimensions of the final product. 3. Compression:The two halves of the mould are closed with force, compressing the material within. This compression ensures that the material fills the entire mould cavity and takes on the desired shape. 4. Curing:Heat is applied to the closed mould, initiating the curing process. During curing, the thermosetting material undergoes a chemical reaction that transforms it from a pliable state to a rigid and infusible one. The curing temperature and time are carefully controlled to achieve the desired properties in the final product. 5. Cooling and Ejection:After the curing process is complete, the mould is allowed to cool down. Once the material has solidified sufficiently, the mould is opened, and the newly formed product is ejected. Significance in Modern Production Thermosetting compression moulding holds immense significance in modern manufacturing for several reasons: 1. Durability:The cured thermosetting products exhibit exceptional durability and dimensional stability. They can withstand high temperatures, chemical exposure, and mechanical stress, making them suitable for demanding applications in aerospace, automotive, and construction industries. 2. Customization:The flexibility in choosing additives and reinforcement materials allows manufacturers to tailor the properties of the final product according to specific requirements. This customization is particularly valuable in industries where specialized components are needed. 3. Mass Production:Despite being a batch process, thermosetting compression moulding can still be employed for mass production. With proper mould design and automation, manufacturers can produce a large volume of consistent and high-quality products. 4. Reduced Waste:Unlike subtractive manufacturing methods, such as machining, compression moulding generates minimal waste. The material is precisely shaped within the mould, reducing the need for extensive post-processing. 5. Wide Application Range:From electrical components to consumer goods, thermosetting compression moulding finds applications in a diverse array of industries. It is used to create items like circuit breakers, cookware handles, automotive parts, and even intricate components in the electronics industry. In conclusion, thermosetting compression moulding stands as a testament to the ingenuity of modern manufacturing processes. Its ability to harness the unique properties of thermosetting materials has paved the way for the creation of durable, high-performance products across various sectors. As technology continues to advance, it is likely that this method will further evolve, expanding its capabilities and applications even further.